Manual actuation

In this type, the spool is operated manually. Manual actuators are hand lever, push button and pedals etc.

Mechanical actuation

The DCV spool can be operated by using mechanical elements such as roller and cam, roller and plunger and rack and pinion etc. In these arrangements, the spool end is of roller or a pinion gear type. The plunger or cam or rack gear is attached to the actuator. Thus, the mechanical elements gain some motion relative to the actuator (cylinder piston) which can be used for the actuation.

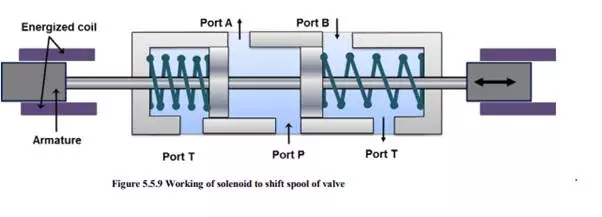

Solenoid actuation

The solenoid actuation is also known as electrical actuation. The schematic of solenoid actuation is shown in Figure 5.5.9. The energized solenoid coil creates a magnetic force which pulls the armature into the coil. This movement of armature controls the spool position. The main advantage of solenoid actuation is its less switching time.

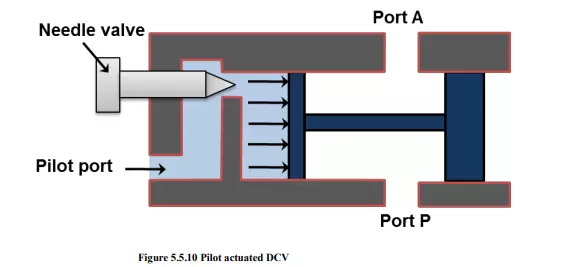

Hydraulic actuation

This type actuation is usually known as pilot-actuated valve and a schematic is shown in Figure 5.5.10. In this type of actuation, the hydraulic pressure is directly applied on the spool. The pilot port is located on one end of the valve. Fluid entering from pilot port operates against the piston and forces the spool to move forward. The needle valve is used to control the speed of the actuation

Pneumatic actuation

DCV can also be operated by applying compressed air against a piston at either end of the valve spool. The construction of the system is similar to the hydraulic actuation as shown in Figure 5.5.10. The only difference would be the actuation medium. The actuation medium is the compressed air in pneumatic actuation system.

Indirect actuation of directional control valve

The direction control valve can be operated by manual, mechanical, solenoidal (electrical), hydraulic (pilot) and pneumatic actuations. The mode of actuation does not have any influence on the basic operation of the hydraulic circuits. Mostly, the direct actuation is restricted to use with smaller valves only because usually lot of force is not available. The availability of limited force is the greatest disadvantage of the direct actuation systems. In practice, the force required to shift the spool is quiet higher. Therefore, the larger valves are often indirectly actuated in sequence. First, the smaller valve is actuated directly and the flow from the smaller valve is directed to either side of the larger valve. The control fluid can be supplied by the same circuit or by a separate circuit. The pilot valve pressure is usually supplied internally. These two valves are often incorporated as a single unit. These valves are also called as Electro-hydraulic operated DCV.

Comments are closed