The components mentioned in this section are referring to the general arrangement drawing of the boiler.

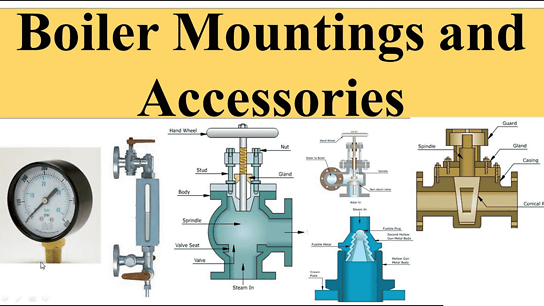

Safety valves

Two safety valves are fitted to the pressure vessel of the boiler. They are installed for security reasons, and designed to prevent the boiler pressure from rising above the design value.

The safety valves must be supplied with waste steam pipes and either expansion devices, or bellows.

Main steam valve

The main steam valve is a shut off valve. When closed, it isolates the boiler from the main steam line. A check valve is mounted after the main steam valve which prevents steam from flowing backwards into the boiler.

The steam piping up to the main steam valve must be flexible in order to minimise external loads on the main steam valve and associated branch. The flexibility can be achieved with loops build into the main steam line to take up heat expansion from the boiler and steam piping or with an expansion joint next to or close to the main steam valve.

By-pass valve

The by-pass valve is a shut off valve. The purpose of the valve is to equalise the pressure between the boiler and the steam system when the main steam valve is closed. Please note that the by-pass valve is only supplied for larger boilers.

Feed water valve / feed valve (SDNR)

Two groups of feed water valves are provided in the boiler. Each group comprises a shut-off valve and a non-return valve. The shut-off valve in the ordinary group must be open when the boiler is in operation, or if the boiler is used as a steam drum. The shut-off valves should be closed when the boiler is not in use.

Water level gauges

Two local water level gauges are connected to the front of the boiler, each gauge being provided with two shut-off valves and a drain valve. The shut-off valves, fitted at the top and bottom of the sight glass, have a quick-closing mechanism to be used in case of broken glass. The pipes from the drain cocks on the water level gauge must lead to an open drain, visible for inspection.

Blow-down valve

Two blow-down valves are mounted at the bottom of the boiler body. If connected to a separate drainage system the valves are of the ball type. When connected to a common drainage system two valves are provided in each group, one shut-off valve and one shut-off/non-return valve. The shut-off function is for security and the non-return function prevents steam/water from flowing into an empty boiler by mistake.

Air valve

The air/ventilation valve located on top of the boiler is a shut-off valve. It is normally closed except when the boiler is being filled or completely drained. The end of the drain pipe from the air valve must be visible in order to determine when water or steam is coming out.

Scum valve

The scum valve is mounted at the top of the boiler body. In the event of scum in the boiler, this scum can be blown off from the water surface by opening this valve. If connected to a separate drainage system the valve is of the ball type. When connected to a common drainage system two valves are provided, one shut-off valve and one shut-off/non-return valve.

Sample valve

A sample valve is installed enabling connection to a sample cooler for taking test samples to perform boiler water analyses.

Inspection hole

Two small inspection holes are provided in the furnace wall to enable inspection of the burner flame. A proportion of the air supply is bled off from the burner fan to cool the window of the inspection hole, and prevent soot deposits.

Manhole

Two manholes placed at the boiler top and boiler bottom allow inside inspection of the steam/water drum.

Access doors

Access to the furnace and smoke outlet box are possible through the access doors placed at the bottom of the furnace and at the smoke outlet box respectively. Both access doors enable inspection of the generating tube bank.

Drain for furnace

The furnace bottom is provided with a socket for drain of the washing water.

Comments are closed