The most important element of any machine is screw threads without screw threads. There can not be any development in the field of engineering. Even machine tools operated by computers. Lead screw threads for moving different slides. The size of screw threads for different purposes varies a fraction of mm to as high as 300 mm. These screw threads are made in quantities from one to several millions. Some screws are to be very accurate and some screws can be very rough. A number of processes are available for manufacturing screw threads. The correct process is selected so that the required quantity and quality of screw threads are produced at the lower cost. Those basic processes are used in the manufacture of threads. They are casting process can be used for producing both external and internal threads. Die casting or investment casting methods are used for producing screw threads in plastics.

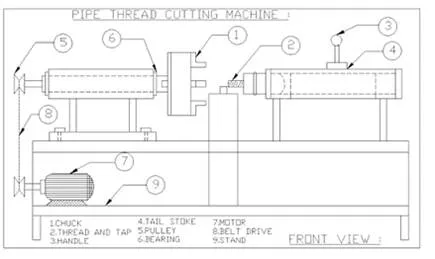

Diagram And parts Of Pipe thread Cutting Machine

Metal cutting process like thread milling, thread grinding and thread chasing are used for producing large variety of screw threads in different sizes. Thread rolling process is used in the mass production of screw threads in ductile materials. Only external threads can be produced in this process. The process is generally restricted to produce simple threads in standard forms.

WORKING PRINCIPLE

In this machine the work is threaded by holding the work piece in three jaw self – centering chuck. The tool is held in the adapter. The adapter is fitted on the hallow shaft. By giving force and turning the handle the spindle moves towards the work piece. By moving this external thread is formed on the work piece. After the formation of thread, the handle is rotated in the reverse direction; the die is removed from the work piece.

ADVANTAGES

1. Accurate threading can be done

2. Setting and operating time is less

3. Number of skilled labour is less

4. Centering of work is easy

5. Both internal and external treading can be done

6. It is used for mass production.

DISADVANTAGES

1. Only single start thread can be done.

2. Threading can be done by upto 1”