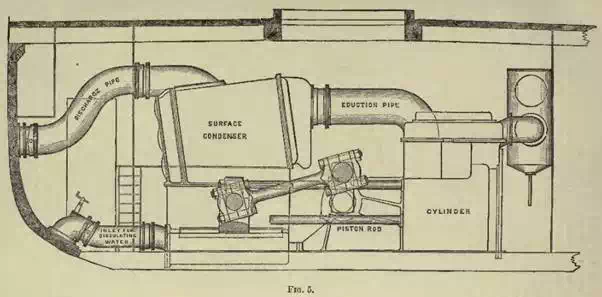

This kind of engine was adopted by the majority of marine engineering firms to enable the horizontal cylinders to be brought close to the crank-shaft, and, as usually fitted, is shown in Fig

There were two rods to each piston, one passing above, the other below the crank-shaft, to the opposite side of the ship, while the further ends of the piston-rods were fixed to a cross-head, having a journal at its centre, from which the connecting-rod worked back to the crank.

In some later examples, in order to obviate the disadvantage of having more than one stuffing-box for each cylinder, and simplify the design of the piston, a single piston-rod was fitted, attached to a cross-head between the cylinder and the crankshaft, from which two rods were carried, one above, the other below, the shaft, to a similar cross-head on the opposite side, as in the ordinary return connecting-rod arrangement.

Direct-acting engines.

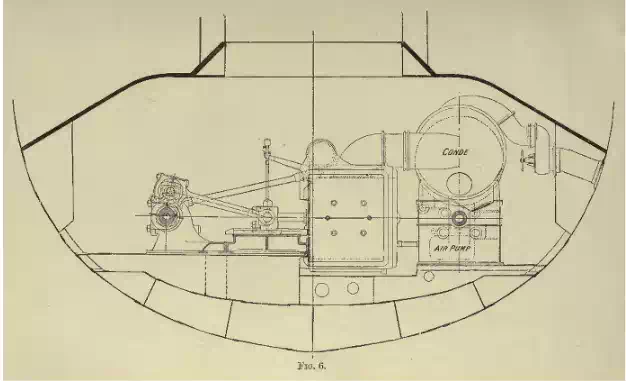

The direct-acting engine shown in Fig. 6, having the connecting-rod between the cylinder and the crank, was often employed, especially by Messrs. Humphrys, in the later horizontal examples, the parts being stowed as compactly as posslble in the limited space available, and a short connecting-rod fitted. It is the simplest type, and the most suitable for general work, and, whenever sufficient room can be obtained, it is usually adopted. For vertical engines, with the cylinders at the top working down to the crank-shaft, which are now generally fitted for marine purposes, this type is universally adopted.