Construction:

• A piston reciprocates inside the cylinder

• The piston is connected to the crankshaft by means of a connecting rod and crank.

• The inlet and exhaust valves are mounted on the cylinder head.

• A fuel injector is provided on the cylinder head

• The fuel used is diesel.

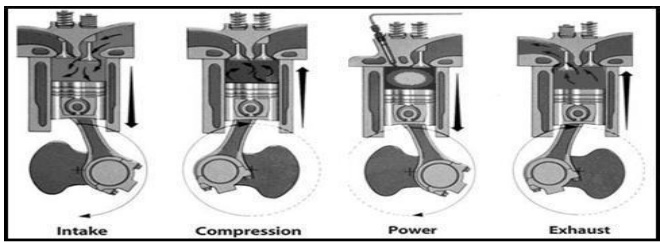

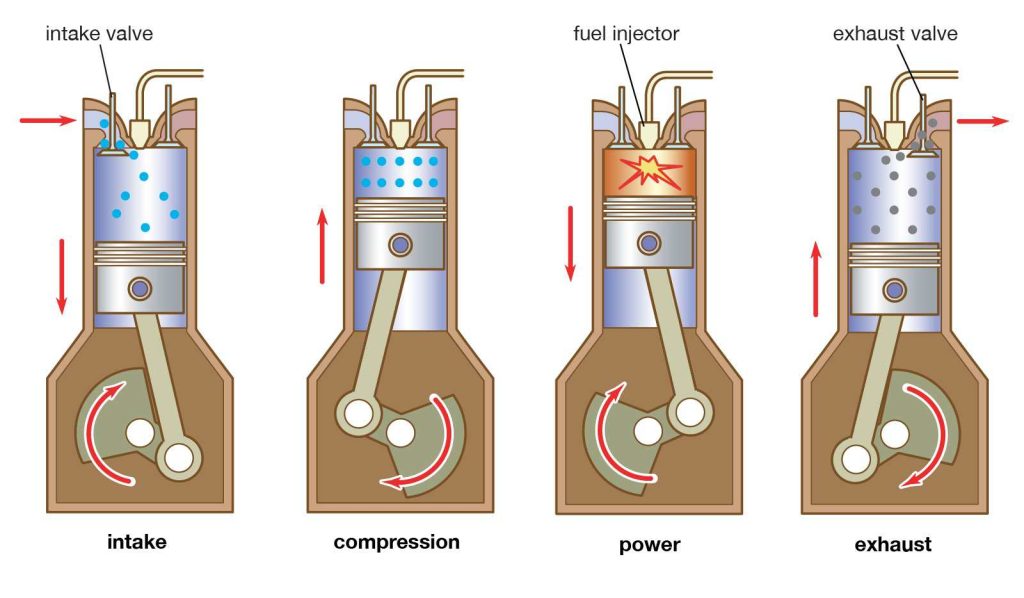

(a) Suction Stroke (First Stroke of the piston)

• Piston moves from TDC to BDC

• Inlet valve is opened and the exhaust valve is closed.

• The pressure inside the cylinder is reduced below the atmospheric pressure.

• Fresh air from the atmosphere is sucked into the engine cylinder through air cleaner and inlet valve.

(b) Compression stroke (Second stroke of the piston)

• Piston moves from BDC to TDC

• Both inlet and exhaust valves are closed.

• The air is drawn during suction stroke is compressed to a high pressure and temperature

(c) Working or power or expansion stroke (Third stroke of the piston)

• The burning gases (products of combustion) expand rapidly.

• The burning gases push the piston move downward from TDC to BDC

• This movement of piston is converted into rotary motion of the crank shaft through connecting rod.

• Both inlet and exhaust valves are closed.

(d) Exhaust Stroke (Fourth stroke of the piston)

• Piston moves from BDC to TDC

• Exhaust valve is opened the inlet valve is closed.

• The burnt gases are forced out to the atmosphere through the exhaust valve. (some of the burnt gases stay in the clearance volume of the cylinder)

• The exhaust valve closes shortly after TDC

• The inlet valve opens slightly before TDC and the cylinder is ready to receive fresh air to start a new cycle.

Comments are closed