Marine cooling systems

The purpose of a cooling system is to maintain a constant temperature throughout the engine that minimises hot spot expansion leading to seizing of the moving parts. Small lightweight auxiliary engines use ambient air cooling with carefully designed cooling fins around the hottest component, the cylinder head. More complex auto engines use a heat exchanger system of a wind cooled fresh water radiator circulating fresh water coolant around the water jackets within the engine block. Water cooling systems are universally used in marine main engines where speed driven cooling is insufficiently constant for reliability. These systems include:

Direct water cooling (fresh or salt);

Heat exchanger cooling (tube or keel cooling).

Direct water cooling

All vessels have an unlimited supply of cooling water over the side. Simpler engines working in fresh water have no difficulty in pumping water up into the internal water jacket that surrounds the engine’s cylinder and dumping the used water back overboard. The water pick up pipe will exclude large waterborne debris with a clam shell external grate. A fine strainer and sacrificial zinc anode may be included. Crude systems such as these rely on flow designed around an average water temperature, and may cool the engine more than the optimum running temperature.

Outboards typically use direct (salt) sea water cooling with its added problem of salt induced corrosion and salt deposit build up. The cooling water pick up is positioned in the outboard leg so designed that water is both directed towards the gear box driven impellor pump and strained of debris. Anti-corrosive constructional metals strategically placed sacrificial anodes and flow design are critical in the piping and water-jacket layout. Moreover, a strict regime of flushing out the motor with fresh water after every trip is essential. Outboard motors have a leak off pipe from the cooling water system called a tell tale placed in a visible position to indicate that water is circulating freely, a requirement being that the leg and water pick up are constantly immersed.

Heat exchanger cooling

The heat exchanger cooling system maintains a constant temperature throughout the engine by removing heat from the hottest part of the engine in the vicinity of the combustion space and transfers it to the cooler parts. Used salt cooling water is ejected directly overboard or via the exhaust. Marine systems are designed to operate at temperatures of typically 85°- 90° C and may be pressurised to raise coolant boil temperature and provide more efficient circulation. An engine can operate intermittently up to 96° with a header tank cap pressure of 103 kPa (1.03 bar or 15 psi). The cooling water high temperature alarms are set at around 96° C

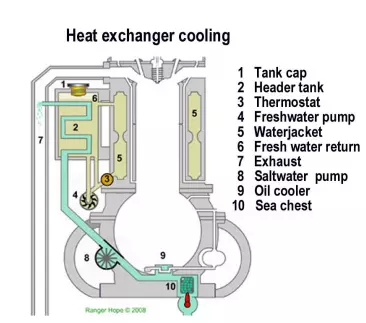

In the schematic system shown below, engine driven pump sucks sea water from the sea chest through the cooler (header tank and heat exchanger) and another circulates fresh water through the engine water jackets and the cooler. The close contact of the engine’s hot fresh water is cooled (heat exchanged) by the piped cold salt water on its way to be ejected (and cool) the exhaust.

The salt water or raw water components include:

Rose or grid – The sea water intake is through a corrosion resistant (bronze or stainless steel 316 grade) rose or grid on the vessel’s hull in order to prevent large pieces of foreign matter entering or blocking the flow.

Sea cock and valve – is attached directly to the inside of the hull so that the sea water can be shut off during maintenance or repair whilst the vessel is afloat.

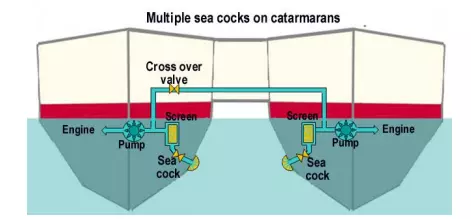

Multi sea cocks are used on catamaran hulls allowing a cross over facility in case one strainer (screen) gets blocked.

On some vessels there is a high and low sea water intake valve. Only one is used at a time. The high one is used for smooth water operations where there is shallow water so that sand and mud are not sucked up into the system. The low one is used at sea so when the vessel rolls, the intake does not come out of the water. It can also be used on smooth water operations where there is deep water.

Strainer or screen- is fitted into the pipe work before the pump, to avoid small foreign matter being drawn into the system. The strainer may be fitted with a sight bowl. The strainer must be easily accessible for frequent cleaning and inspection. A sacrificial zinc anode plug is often fitted to the top of the sea chest.

Sea water pump – is an engine or belt driven positive displacement pump, usually of the flexible impellor type (often called after the common brand, Jabsco)

Fresh water cooler – The cooler is on the discharge side of the sea water pump and is usually protected against the corrosive effect of the water by a sacrificial zinc anode plug. To further protect against salt water corrosion the constructional materials used are non corrosive and consistent in their electrolytic reactivity.

Exhaust box or swan neck – In a wet exhaust system the raw water is ejected into the exhaust flow to cool and quieten the exhaust. It is injected into the exhaust pipe after a gravity lock (a bend or bucket) in such a way that water will not drain back through the exhaust manifold and into the cylinders. This is to prevent the potential for serious damage of turning over uncompressible water filled cylinders (hydraulicing) and/or introducing a corrosion source. This remains a possibility if an engine is repeated turned over without starting, as the build-up of salt water may over flow the water lock. More complex engines may have a salt water leak off pipe with control valve whereby exhaust back pressure generated by the salt water injection into the exhaust can be optimally adjusted to manufacturer’s specification. Some vessels use an insulated dry exhaust and eject the used raw water directly overboard.

The fresh water or coolant circulation components include:

Fresh water or coolant circulation – The circulating liquid may be fresh water of a mix of water and additives. Coolant glycol based additive (often called antifreeze) assists to reduce corrosion, minimise freezing, raise boiling point and promote efficient coolant flow. Such corrosion inhibitors have a maximum service life and should be replaced as recommended by the manufacturer. In most high speed engines the fresh water system is pressurised both to raise the boiling point and to promote efficient pumping. Care must be taken when opening the cap of a warm header tank that the release of pressure does cause a gushing release of boiling water and steam.

The top of the cylinder liner and the inlet and exhaust valve area are where combustion takes place. Fresh water with additives called coolant is circulated under pressure through the block and cylinder head to cool this hottest part of the engine.

There are spaces around the cylinder liner and the block that are called jackets. The fresh water circulates through them. The fresh water then flows through the holes in the top of the block and corresponding holes in the cylinder head gasket and cylinder head. In the cylinder head the water circulates around the inlet and exhaust gas passages to the thermostat.

The fresh water in some engines may be fed through the exhaust manifold and turbo charger. Cooling them minimises the radiant heat given off thereby keeping the engine space cooler and providing better engine power. Fresh water cooling of these parts does not leave the deposits that sea water cooling does.

Fresh water or coolant pump – is engine driven and as it is constantly immersed (needing no priming) is usually of the low maintenance centrifugal type.

Header tank or expansion tank – This allows for expansion of the fresh water as it heats. Modern engines typically also have a vent and additional overflow reservoir. The tank provides an adequate method of venting air and combustion gases from the fresh water system during engine operation. Since combustion gases may enter the fresh water system, it will be necessary to remove these gases before they cause deterioration of the engines cooling water system’s performance. Gases in the system reduce coolant flows and may result in engine failure if adequate venting capacity is not provided. In many engines the header tank is situated above the fresh water cooler to form one unit.

Venting – Initial venting of the system is critical in order to ensure that the system is completely filled with coolant. Fill the engine slowly to allow the coolant to fill from the bottom up. Quickly filling the expansion tank can fill the vent pipes with coolant and result in slow or incomplete fill of the engine. If vent cocks are fitted, they are to be used to help any air to escape. After initial filling of the system, run the engine, keep checking and if necessary top up the water level until the coolant operating temperature is reached. Any trapped air should make its way up to the header tank in the form of bubbles.

Thermostat – A thermostat is a heat sensitive valve that enables the engine to reach its normal operating temperature quicker to minimise warming up wear. When the engine is cold, the closed thermostat closes the coolant off from the heat exchanger. When the engine reaches its normal operating temperature the thermostat opens and directs the water to the heat exchanger.

Heat exchanger or fresh water cooler – The heat exchanging process takes place below the header tank. When the thermostat is open, fresh water will flow through the bath of the cooler (shell) and be cooled by the nest of tubes through which the raw water flows, hence the name of a tube nest and shell heat exchanger.

Comments are closed