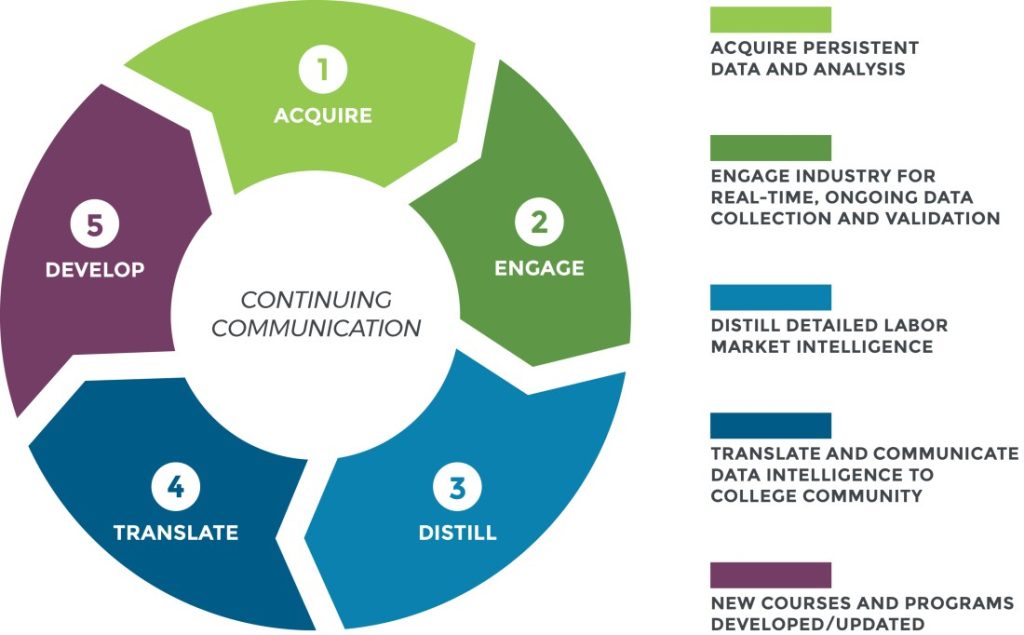

A sequence of four operations called the work cycle must occur for engines to work:

Induction – a charge of air (diesels) or air/fuel mix (petrol) is directed into the cylinder to provide the oxygen required for combustion.

Compression – the charge is compressed to optimise the result of combustion. Power – the air/fuel mix (petrol) is ignited by a spark, or with diesels the fuel is injected to ignite in the superheated compressed air. The expansion of the gasses from this explosive ignition exerts a force upon the piston that turns the crankshaft.

Exhaust- The products of this explosion (the exhaust gasses) is ejected so the cycle can be repeated.

The work cycle of induction (suck), compression (squeeze), power (bang) and exhaust (push) are achieved by differing configurations or types of engines including four stroke or two stroke engines. The term stroke means the directional travel of the piston along the cylinder from tdc – bdc or from bdc – tdc.

The four-stroke engine takes two complete revolutions of the crankshaft to complete the work cycle. The two-stroke does it in one complete revolution of the crankshaft. This means that a two-stroke engine has twice as many power operations as a four stroke engine at the same speed, so it may produce more power and acceleration but at the expense of fuel efficiency and reliability.

Petrol or diesel

Due to availability and convenience of handling, petrol (or gasoline) and diesel (or distillate) are the most common small vessel marine propulsion fuels. Larger vessels often use a cheaper and less refined tarry fuel oil requiring heat to liquefy sufficiently for the combustion process. Petrol and diesel are cocktails of hydrocarbons wth differing flash points, commonly from – 40°C to 0°C for petrol and 60°C for diesel, this being the temperature that they will vapourize to ignite. Diesel’s higher flash point makes it safer than petrol as any escaping fuel vapours can pool in a boat’s bilges with consequent risk of explosion.

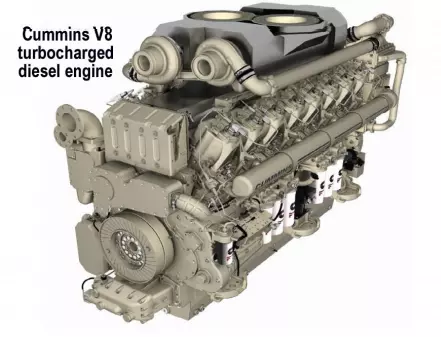

The diesel engine uses the piston’s sweep of the cylinder from bdc position up to tdc position to compress the inducted air, raising its pressure and consequent heat to such an extent (1000ºC) that when fuel is injected it immediately ignites. Diesel engines need a high compression ratio compressed the air sufficient to reach the temperature for ignition. A 16:1 to 20:1 compression ratio, common to small high speed diesel engines means that the air has been compressed to one-sixteenth or one twentieth of its original volume. The wall of the cylinder needs to be heavy gauge to contain the pressure.

Considerable power is needed to overcome that amount of compression to get a diesel engine started. Larger diesel engines have decompression levers that open the cylinder to the atmosphere so relieving the force needed for the starter mechanism to get the engine turning over. When the flywheel is spinning rapidly they are closed for the first compression and power operation to start.

The petrol engine, using the more flammable fuel, can ignite the fuel/air mix by an electrically generated ignition source at its spark plug, more fully described in Chapters 1.4 and 8.2. A compression ratio of 10:1, common to small high speed petrol engines means that the air has been compressed to one-tenth of its original volume, requiring less energy to turn over in starting than the diesel.

While advances in design are ever improving, the advantages and disadvantages of the typically ponderous but reliable diesel against the responsive but explosive petrol is demonstrated in the proliferation of diesel engines for inboard installation (required for commercial vessels) and petrol engines for outboards. In short, the strengths and weaknesses of petrol versus diesel engines can be summarised as:

Petrol driven engines use fuel with high fire risk, require electrical sparking that is not ideal in a damp environment but can be low weight for power capacity with high acceleration performance.

Diesel driven engines operate using a fuel with lower fire risk, do not rely on electrical connections but can be heavy for power capacity with slow naturally aspired acceleration balanced by reliability and longevity. Though of a heavier build than petrol engines, in order to sustain the forces resulting from higher compression, they are known for producing working power (grunt) at lower speeds