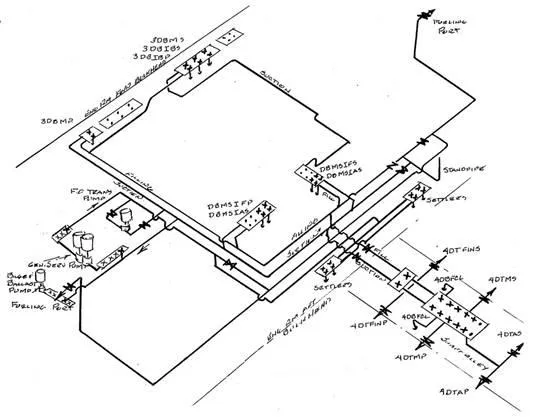

There are two fuel oil filling stations on the “B” Deck located at frame 125 port and starboard sides. Fuel oil filling lines from each station are combined into a common 8″ filling and discharge main. The fuel oil main is connected to the fuel oil side of the double manifolds in the fuel oil and oily ballast system; on the other side of the manifolds, pipe is led from each pair of valves in the double manifolds to one of the fuel oil tanks. These single lines connecting the manifolds and tanks are thus used for fuel oil suction and discharge, and oily ballast suction and discharge.

Reference should be made to the capacity tables for a tabulation and location of the various fuel oil and ballast tanks.

All tank filling, transfer and discharge services are controlled at double valve manifolds. In addition to local manual operation, the double valve manifolds for the port and starboard fuel oil settling tanks are equipped with air-operated heads for remote operation. On the manifolds, the stop valves on the oily ballast side are interlocked with its corresponding valve on the fuel oil transfer side. This prevents opening the valve to the ballast main when pumping fuel oil and vice versa.

Double valve manifolds serving the fuel oil or ballast tanks have 3/4″ hose valve connections on the manifold for blowing out cold plugs of oil in the tail pipes with steam.

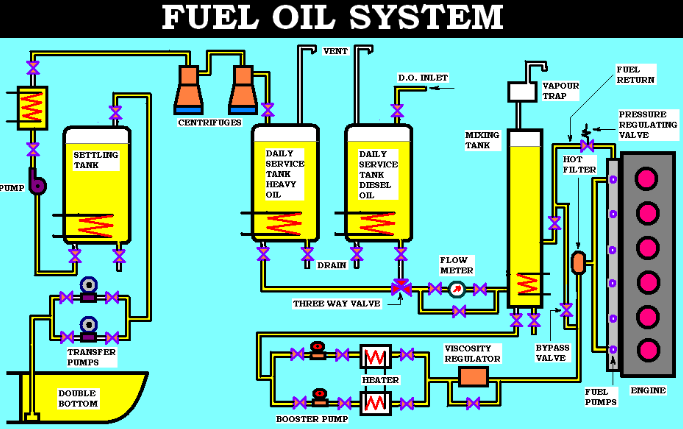

A motor driven, vertical rotary fuel oil transfer pump is installed in the engine room. This pump has a capacity of 225 gpm at 100 ft. total head. The discharge side of the pump is protected from excessive pressure by a relief valve set at 110 psig.

The fuel oil transfer piping is arranged to permit the following flexibility:

- Discharge of fuel oil from filling stations to all tanks.

- Transfer of fuel oil from any storage tank to the settling tanks.

- Transfer fuel oil in either direction between port and starboard inboard, outboard or centerline inner-bottom tanks.

- Discharge fuel oil to filling stations from any fuel oil tank.

Four fuel oil settling tanks are provided. To reduce the possibility of contaminated oil reaching the burners, any water that may have been introduced into the oil during storage or transfer should be allowed to settle out before the fuel is used. When water has settled to the bottom of the tank, it can be removed with the fuel oil transfer pump. On most ships the low suction is normally used. If the burner flame sputters or goes out due to water contamination, the settler suction can be quickly switched to the high suction. On the Patriot State, we normally use the high suction, and switch to alternate settlers in the event of contamination.

The fuel oil settling tanks are fitted with independent overflows that discharge overboard through a common sea chest after passing through individual swing check valves. There is a disc type check valve located before the sea chest. The sea chest itself is located about 31′-4″ above the base line of the ship.

Each fuel oil settling tank is fitted with a high level alarm to give warning against excessive filling. Contacts operate when level rise to 18″ from top of tank, sounding an alarm.

The oily ballast system is served by the bilge and ballast pump. This pump is a motor driven, single stage, vertical, centrifugal type unit with capacity of 600 gpm at 60 ft. total head.

Stand-by service is provided for the oily ballast system by the general service pump.

Through the double valve manifolds, which service the fuel oil filling, transfer and oily ballast systems, the bilge and oily ballast pump delivers salt water ballast to the fuel oil or ballast tanks. Ballast is withdrawn from these tanks through the same manifolds.

Comments are closed