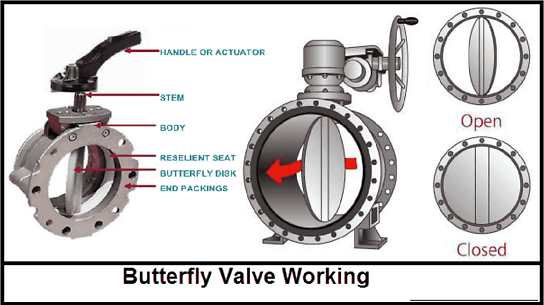

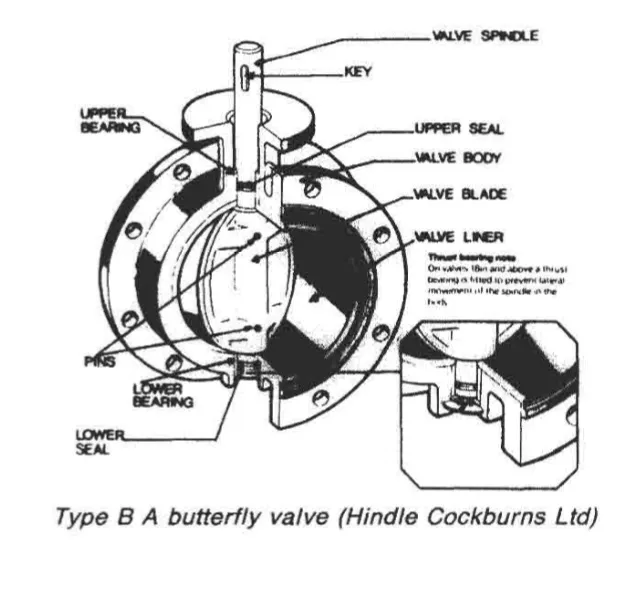

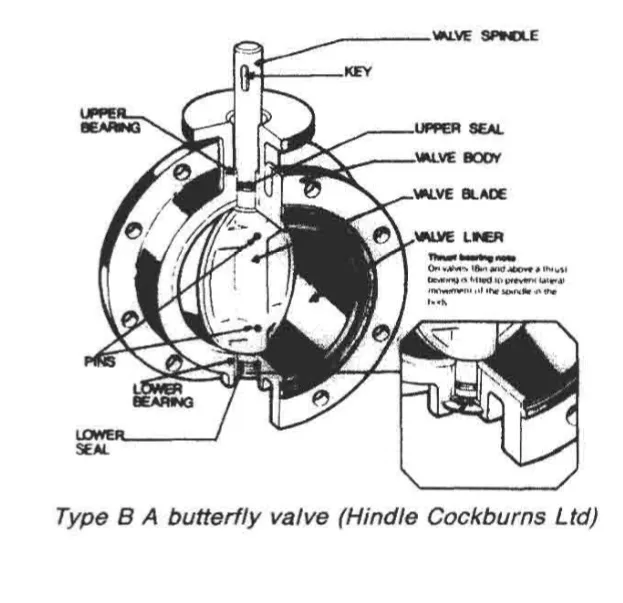

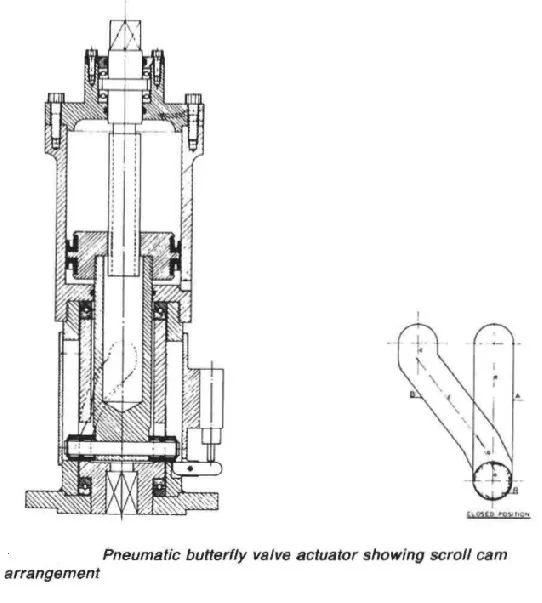

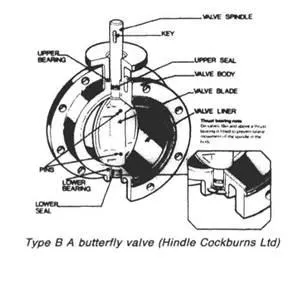

A butterfly valve consists basically of a disc pivoted across the bore of a ring body having the same radial dimensions as the pipe in which it is fitted. The full bore straight through flow arrangement of this type of valve, especially if combined with a carefully streamlined disc profile, gives excellent flow characteristics and low pressure drop. (Figure 1)

Figure 1 : Type B A butterfly valve (Hindle Cockburns Ltd)

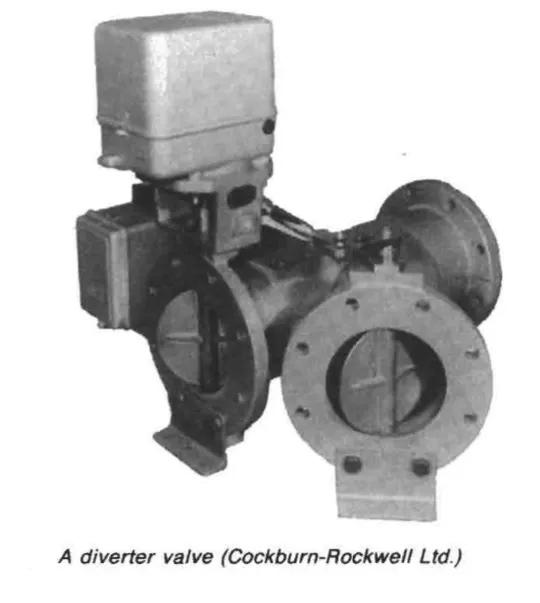

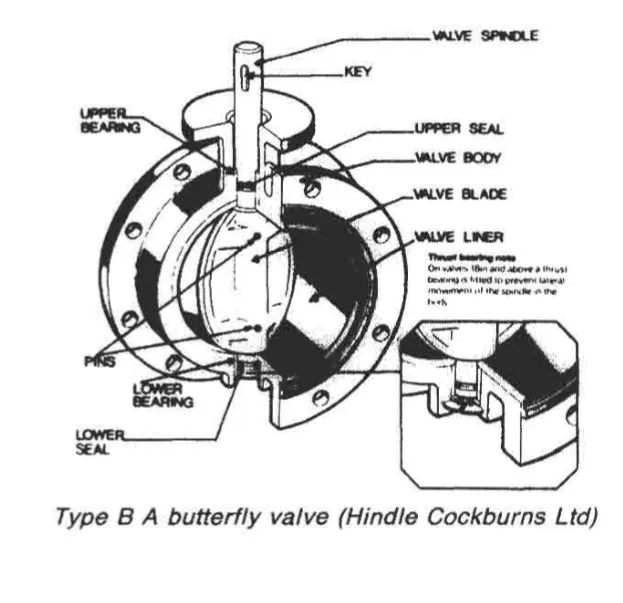

The valve is quick-acting if required, as only a quarter of a turn of the spindle is required to move the valve from the fully open to the fully closed position. Sizes range from 6 mm to over 1000 mm bore. For fine control of cooling water temperature a special type of ganged butterfly valve may be used to bypass coolers. Known as a diverter valve it consists of a Y or T casting with butterfly valves in two of the legs (Figure 2),

Figure 2: A diverter valve (Cockburn-Rockwell Ltd.)

A pneumatic actuator working from a signal provided by a temperature sensor opens one valve while closing the other. This gives precise control of the flow rate in the main and branch lines. In the event of a temperature controller failure, a built-in return spring opens or closes the main and branch lines (as appropriate to the system of operation) to provide maximum cooling flow. Manual control is available for emergencies.

Valve actuators

A variety of valve actuators to control the opening and closing of globe, gate and butterfly valves are available. In some types an electric motor, fitted with limit switches is used to turn a threaded stem through a yoke, purely substituting the action of a handwheel.

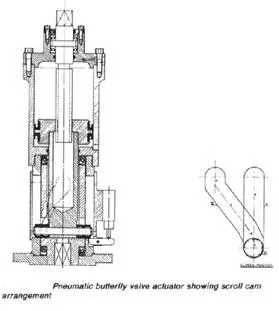

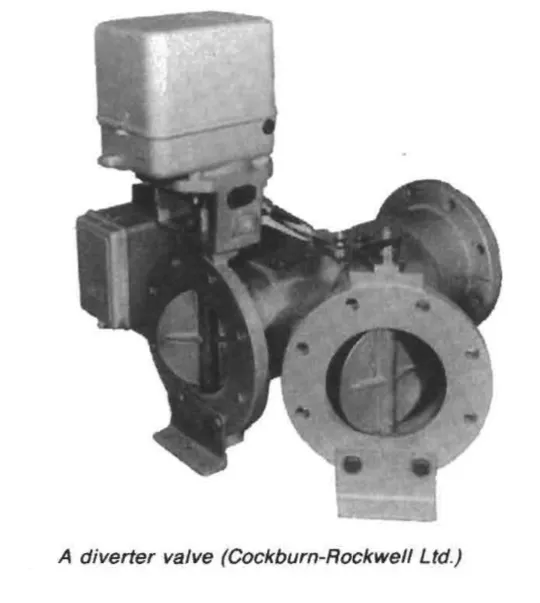

Most remotely operated valves have pneumatic or hydraulic actuators. These give linear motion to a piston which for a globe or gate valve moves the valve stem axially up or down. The globe valve disc may be given a slight turn on landing to clean the seat. The piston actuator for a butterfly valve rotates the valve disc through 90° directly or through a scroll arrangement (Figure 3 )

Figure 3:Pneumatic butterfly valve actuator showing scroll cam arrangement Butterfly valves

A butterfly valve consists basically of a disc pivoted across the bore of a ring body having the same radial dimensions as the pipe in which it is fitted. The full bore straight through flow arrangement of this type of valve, especially if combined with a carefully streamlined disc profile, gives excellent flow characteristics and low pressure drop. (Figure 1)

Figure 1 : Type B A butterfly valve (Hindle Cockburns Ltd)

The valve is quick-acting if required, as only a quarter of a turn of the spindle is required to move the valve from the fully open to the fully closed position. Sizes range from 6 mm to over 1000 mm bore. For fine control of cooling water temperature a special type of ganged butterfly valve may be used to bypass coolers. Known as a diverter valve it consists of a Y or T casting with butterfly valves in two of the legs (Figure 2),

Figure 2: A diverter valve (Cockburn-Rockwell Ltd.)

A pneumatic actuator working from a signal provided by a temperature sensor opens one valve while closing the other. This gives precise control of the flow rate in the main and branch lines. In the event of a temperature controller failure, a built-in return spring opens or closes the main and branch lines (as appropriate to the system of operation) to provide maximum cooling flow. Manual control is available for emergencies.

Valve actuators

A variety of valve actuators to control the opening and closing of globe, gate and butterfly valves are available. In some types an electric motor, fitted with limit switches is used to turn a threaded stem through a yoke, purely substituting the action of a handwheel.

Most remotely operated valves have pneumatic or hydraulic actuators. These give linear motion to a piston which for a globe or gate valve moves the valve stem axially up or down. The globe valve disc may be given a slight turn on landing to clean the seat. The piston actuator for a butterfly valve rotates the valve disc through 90° directly or through a scroll arrangement (Figure 3 )

Figure 3:Pneumatic butterfly valve actuator showing scroll cam arrangement Butterfly valves

A butterfly valve consists basically of a disc pivoted across the bore of a ring body having the same radial dimensions as the pipe in which it is fitted. The full bore straight through flow arrangement of this type of valve, especially if combined with a carefully streamlined disc profile, gives excellent flow characteristics and low pressure drop. (Figure 1)

Figure 1 : Type B A butterfly valve (Hindle Cockburns Ltd)

The valve is quick-acting if required, as only a quarter of a turn of the spindle is required to move the valve from the fully open to the fully closed position. Sizes range from 6 mm to over 1000 mm bore. For fine control of cooling water temperature a special type of ganged butterfly valve may be used to bypass coolers. Known as a diverter valve it consists of a Y or T casting with butterfly valves in two of the legs (Figure 2),

Figure 2: A diverter valve (Cockburn-Rockwell Ltd.)

A pneumatic actuator working from a signal provided by a temperature sensor opens one valve while closing the other. This gives precise control of the flow rate in the main and branch lines. In the event of a temperature controller failure, a built-in return spring opens or closes the main and branch lines (as appropriate to the system of operation) to provide maximum cooling flow. Manual control is available for emergencies.

Valve actuators

A variety of valve actuators to control the opening and closing of globe, gate and butterfly valves are available. In some types an electric motor, fitted with limit switches is used to turn a threaded stem through a yoke, purely substituting the action of a handwheel.

Most remotely operated valves have pneumatic or hydraulic actuators. These give linear motion to a piston which for a globe or gate valve moves the valve stem axially up or down. The globe valve disc may be given a slight turn on landing to clean the seat. The piston actuator for a butterfly valve rotates the valve disc through 90° directly or through a scroll arrangement (Figure 3 )

Figure 3:Pneumatic butterfly valve actuator showing scroll cam arrangementA butterfly valve consists basically of a disc pivoted across the bore of a ring body having the same radial dimensions as the pipe in which it is fitted. The full bore straight through flow arrangement of this type of valve, especially if combined with a carefully streamlined disc profile, gives excellent flow characteristics and low pressure drop. (Figure 1)

Figure 1 : Type B A butterfly valve (Hindle Cockburns Ltd)

The valve is quick-acting if required, as only a quarter of a turn of the spindle is required to move the valve from the fully open to the fully closed position. Sizes range from 6 mm to over 1000 mm bore. For fine control of cooling water temperature a special type of ganged butterfly valve may be used to bypass coolers. Known as a diverter valve it consists of a Y or T casting with butterfly valves in two of the legs (Figure 2),

Figure 2: A diverter valve (Cockburn-Rockwell Ltd.)

A pneumatic actuator working from a signal provided by a temperature sensor opens one valve while closing the other. This gives precise control of the flow rate in the main and branch lines. In the event of a temperature controller failure, a built-in return spring opens or closes the main and branch lines (as appropriate to the system of operation) to provide maximum cooling flow. Manual control is available for emergencies.

Valve actuators

A variety of valve actuators to control the opening and closing of globe, gate and butterfly valves are available. In some types an electric motor, fitted with limit switches is used to turn a threaded stem through a yoke, purely substituting the action of a handwheel.

Most remotely operated valves have pneumatic or hydraulic actuators. These give linear motion to a piston which for a globe or gate valve moves the valve stem axially up or down. The globe valve disc may be given a slight turn on landing to clean the seat. The piston actuator for a butterfly valve rotates the valve disc through 90° directly or through a scroll arrangement (Figure 3 )