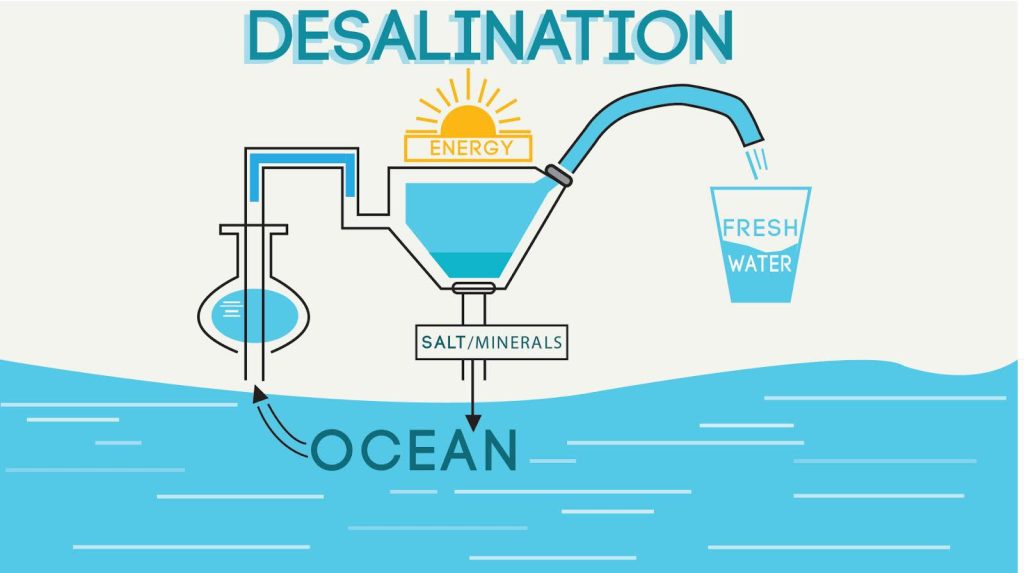

Water desalination processes separate dissolved salts and other minerals from water. Feedwater sources may include brackish, seawater, wells, surface (rivers and streams), wastewater, and industrial feed and process waters. Membrane separation requires driving forces including pressure (applied and vapor), electric potential, and concentration to overcome natural osmotic pressures and effectively force water through membrane processes. As such, the technology is energy intensive and research is continually evolving to improve efficiency and reduce energy consumption.

Seawater desalination has the potential to reliably produce enough potable water to support large populations located near the coast. Numerous membrane filtration seawater desalination plants are currently under construction or in the planning stages up and down California’s parched coast, with the 50 million gallons per day (mgd) Carlsbad Desalination plant scheduled to be operational by 2016.

Reverse osmosis (RO) and Nanofiltration (NF) are the leading pressure driven membrane processes. Membrane configurations include spiral wound, hollow fiber, and sheet with spiral being the most widely used. Contemporary membranes are primarily polymeric materials with cellulose acetate still used to a much lesser degree. Operating pressures for RO and NF are in the range of 50 to 1,000 psig (3.4 to 68 bar, 345 to 6896 kPa).

Electrodialysis (ED) and Electrodialysis Reversal (EDR) processes are driven by direct current (DC) in which ions (as opposed to water in pressure driven processes) flow through ion selective membranes to electrodes of opposite charge. In EDR systems, the polarity of the electrodes is reversed periodically. Ion-transfer (perm-selective) anion and cation membranes separate the ions in the feed water. These systems are used primarily in waters with low total dissolved solids (TDS).

Forward osmosis (FO) is a relatively new commercial desalting process in which a salt concentration gradient (osmotic pressure) is the driving force through a synthetic membrane. The feed (such as seawater) is on one side of the semi permeable membrane and a higher osmotic pressure “draw” solution is on the other side. Without applying any external pressure, the water from the feed solution will naturally migrate through the membrane to the draw solution. The diluted solution is then processed to separate the product from the reusable draw solution.

Membrane Distillation (MD) is a water desalination membrane process currently in limited commercial use. MD is a hybrid process of RO and distillation in which a hydrophobic synthetic membrane is used to permit the flow of water vapor through the membrane pores, but not the solution itself. The driving force for MD is the difference in vapor pressure of the liquid across the membrane.

Comments are closed