A tidal barrage is a marine renewable energy device dependent on the flooding and ebbing of the tides. It consists of a barrage built across an estuary that allows the seawater to fill the area behind the barrage through gates during flood tide, then empty at ebb tide via turbines driving generator.

Following our examination of wave energy converters and tidal energy extraction devices in previous articles, we will now look at tidal barrages, which are another way used to produce electricity from tidal energy.

A barrage tidal plant consists of a barrage built across an estuary. This barrage has integral gates allowing the area behind it to fill with seawater at flood tide, emptying on the ebb tide through water turbines that generate power. A tidal barrage is undoubtedly one of the most controversial methods of extracting energy from the sea, mainly because of environmental concerns, but it is regarded as a form of renewable energy.

With the ever-escalating costs of fossil fuels and the availability of them to thermal power stations, the UK government were again looking into tidal barrage as a means of generating electricity to the national grid. The River Severn Estuary Tidal Barrage has been the subject of many government studies. However in 2010, the UK Government shelved further studies for this project, proposing numerous nuclear plants instead to lower power plant CO2 emissions.

In the following sections we examine operating principles of tidal barrage, along with three different types of turbines that are suitable to drive the power generators.

The Operating Principles of a Tidal Barrage

Once the site for the tidal barrier has been selected, an extensive Environmental Impact Statement must be prepared by the nominated contractor. This must take into account any effect on fish, waterfowl, and local flora and fauna. Once completed it is submitted to the relative government department and when approved, the massive civil works contract lasting up to five years can commence as noted below.

There are several proposed methods of construction, very briefly…

A foundation for the barrier is laid, usually from rocks from a local supply, then piles are driven in before concrete is poured to form the barrier. As it is being constructed, apertures are formed to accommodate the turbines and sluice gates along with a lock facility, if required, that will allow the passage of ships.

Foundations are laid then pontoons are constructed from concrete or steel incorporating the sluice gates, and shipping locks. The turbines are floated to the location and ballasted to sink onto the founds (var. “molds”). They are piled into the founds and joined to form the barrage and road/rail links are then laid atop.

The components of the barrage are as follows.

· Sluice Gates – these allow the seawater to fill behind the barrage

· Turbines – there are currently three types used to drive the power turbines.

· Power Generators – these can be submerged or built above the turbines driven by a vertical or inclined shaft.

· Lock Gate – some of the dissenters are against barrages because it stops the passage of ships up the river. A lock gate can facilitate this.

· Basin – the area behind the barrier, this can prove a recreation facility for sailing, fishing and

other water sports.

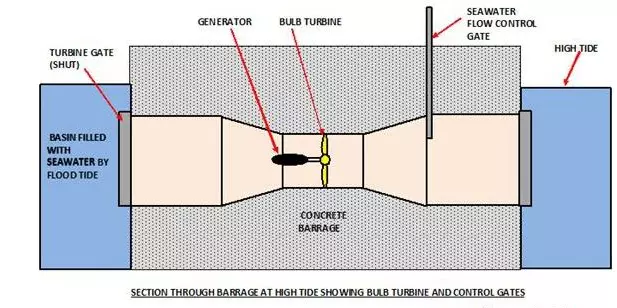

Operational Overview

The incoming tide fills the basin, which is the area behind the barrage, through the sluice gates that are then closed at high tide. The sluice gates remain closed and once the ebb tide has receded below the barrier sluice gates, the turbine gates are opened. This allows the seawater to pass out through the turbines producing a large electrical output of power via the generators. This power generation can be extended by allowing the incoming tide to pass through the turbines as it fills up the basin on the flood tide, but this is both inefficient and uneconomical, and therefore most designs incorporate a one-way power generation system.

However, if the turbine can be reversed with the generator used as a drive motor, water can be pumped into a storage area using cheap electricity. This normally operates at night, and then used to generate power at high demand times charging premium rates.

The sketch below shows a section through the barrier turbine aperture, with a bulb turbine installed.

Tubular Turbine

This turbine is the most recent innovation and was selected as the preferred type for the river Severn barrage.

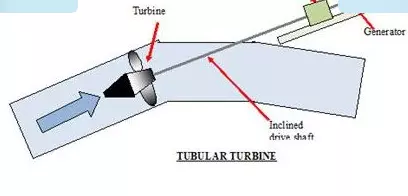

It is a three bladed turbine that is mounted at an angle in the aperture in the barrage. The generator drive shaft protrudes upwards to the generator that is mounted on the concrete structure above the waterline.

Once again this allows for maintenance of the generator without withdrawal from the water, but cannot be reversed to operate on flood tide or used to pump storage.

A sketch showing a typical tubular turbine follows

Bulb Turbine

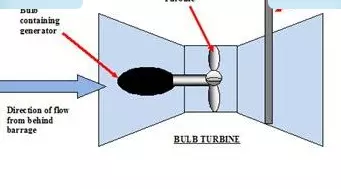

This is the type of turbine used at the La Rance river estuary on the coast of France, where it has been generating 240MW since the sixties. The generator is contained within a bulb, with the turbine and generator being completely submerged. The turbine and generator are reversible either to generate power on the flood tide or act as a motor to pump seawater for storage in an integrated basin or to supplement the stored water behind the barrage, as discussed earlier.

The big disadvantage with the bulb turbine generator is that it has to be lifted clear of the water for generator maintenance

A sketch of a typical bulb turbine is shown below.

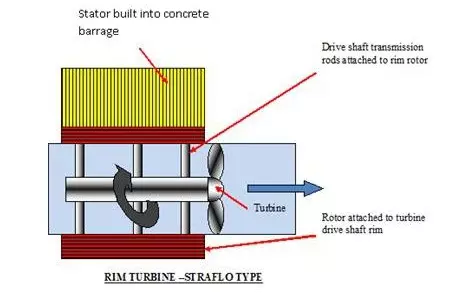

Rim Turbine

This type of turbine has been used in a few small output tidal barrages, but larger versions have had trouble with water seals. However the rim turbine is used successfully in a lot of “run of river” hydropower plants, such as one on the River Rhine.

The generator rotor is located in the rim of the turbine with the stator on the barrage structure. This leads to a more compact, but less flexible component that can only operate one way – on the ebbing tide. It also has the disadvantage of having to be removed for maintenance of the turbine, but the generator can be accessed the when water inlet gate has been closed and the water drained off.

A sketch of a typical rim turbine follows.