Air ejectors on a ship help in removing air blocks from the ship’s feed water system. There are several types of air ejectors used on ships. The article describes as to how an air ejector works and what are its important parts are.

Removing any amount of trapped air from working systems on a ship is an essential task. Trapped air is mainly found in systems which deal with carrying steam and vapours. Air in the system not only leads to loss of differential pressure across the system but also to many harmful conditions in the long term. One such system on ship wherein air is commonly found is the feed water system. To eradicate the problem of trapped air from feed water system, air ejectors are used. We will learn how an air ejector works in the following article does.

Air Ejector Theory

ejector is an essential component of any type of feed system on the ship. As the name suggests, the equipment completely removes the air from any system and also draws out the vapours released from the condensing steam in the condenser.

Presence of air in the system leads to several detrimental effects on the boiler. Corrosion is one such effect that in long run results is failure of the boiler from the inside. Also, the accumulation of air inside the condenser affects the condensing process, which results in the production of back pressure. The back pressure thus generated leads to increase in exhaust steam pressure and reduction in thermal efficiency of the plant. Let’s take a look at the construction and working of conventional air ejectors.

Construction of a Simple Air Ejector

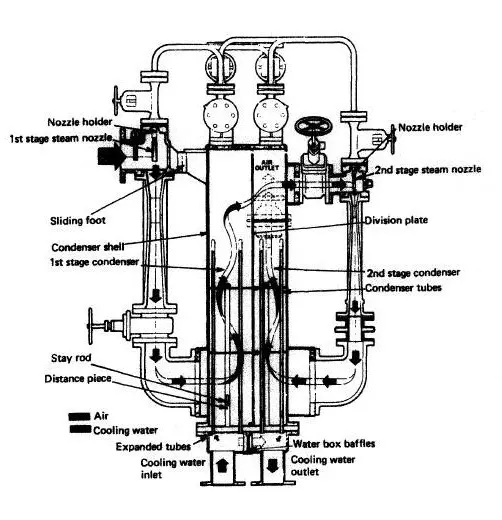

For understanding purpose, we would consider a two stage twin element air ejector. This type of air ejectors are usually steam operated. The air ejector system is divided into two main stages. The first stage acts as a pump to draw in the air and vapours from the condenser and the condensing unit of the system forms the second part. Not all the part of the steam entering the second stage is converted into condensate and for this reason, a return line is provided for the non-condensed steam to go back to the second stage. The feed water for the cooling purpose is supplied to both the stages through a U-tube arrangement as shown in the figure.

How Does an Air Ejector Work?

The air from the condenser or any other part of the system is sucked in by the first stage of the air ejector, which acts as a pump. The air and vapours then passes to the second stage which is a condensing unit. A continuous circulation of feed water inside the condensing unit cools the steam and vapours entering the second stage. The condensed steam through a drain goes to the main condenser unit of the feed system. All the remaining air and vapour that are not condensed in the second stage are sent back to the condensing unit through a return line and the process is repeated again. Any other gases are released to the atmosphere through a vacuum retaining valve.

Air ejectors are always mounted in pairs in the feed system. Though only one is required for appropriate functioning of the system, the alternate air ejectors act as standby or helper units. Adequate numbers of valves are fitted on the steam, vapour and feed water line to isolate each line whenever required.