The use of lubricants and lubricant parameters on ships is an important role managed by the main engine lube oil system. This consists of a pump that pressurizes the oil, circulating it through a set of filters and a cooler before distribution to all the moving components of the diesel engine

Lubrication is necessary to help overcome the evil of friction; lubricant oils can be animal (whale oil), vegetable (linseed), or mineral (petroleum). All three types of lubricant have been used over the centuries to dissipate heat, reduce friction and combat wear and tear between the surfaces of two moving components.

Nowadays however we have a choice of two main types of lube oil;

· Mineral Lubricants – these are obtained from the processing of crude oil.

· Synthetic Oils – a relatively new innovation involving the use of polyglycols or esters.

In the following sections we shall examine the use of mineral lube oil, and its application to marine diesel engines. The use of low quality lubrication oil can lead to several problems, and it is also necessary to maintain the original properties of the oil.

The first section provides an overview of mineral lube oil properties.

An Overview of the Properties of Lubricating Oils

Properties of Lubricating Oils

· Viscosity

This is the most important property of any lubricant; the oil’s ability to flow at particular or specified temperatures and pressures. The viscosity must be calculated by taking into consideration the application and operating temperature range. For example, if the viscosity of the oil is too great, it will affect the operation of the moving components against each other-offering greater resistance to motion, alternatively if the viscosity is too low then it can flow too freely between the surfaces of the components, failing to lubricate them properly.

· Volatility

Volatility is the ability of the oil to ignite due to a low flash point. This is of particular importance when preventing crankcase explosions – if its flash point is low, it will ignite due to the high temperature of a hot spot causing an explosion. The flash-point of a marine diesel engine lube oil should be above 200°C.

· Alkalinity

This is especially important for the cylinder lubrication, as it acts as a neutralizer to the acidic sulphur residues from combustion of HFO.

· Detergents

these are added to the lube oil to inhibit the formation of deposits of the moving components; also helps to keep the oil clean.

· Oiliness

Often referred to as the ‘stickability’ of the oil – its ability to adhere to the surfaces such as white metal bearings.

To maintain the lubricating oil’s operating parameters and properties, the temperature and pressure must be controlled, this being the duty of a watchkeeping engineer. The solids and water should be removed from the oil through centrifuging, often carried out continuously.

Main Engine Lube Oil System

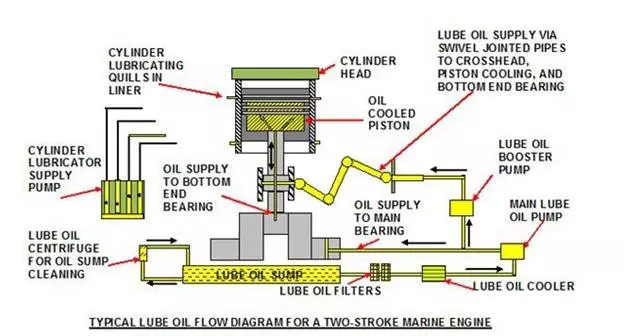

· The oil is pumped from the main engine sump, through a set of duplex oil filters, on through the lube oil cooler and around the main engine components under pressure, in the following manner;

· It is pumped into the main bearings, preventing contact between the steel shaft and the white metal bearings.

· The oil is also being supplied through swivel jointed pipes inside the engine casing, to the crossheads, and guides, piston cooling and bottom end bearings, the oil pressure being increased by a booster pump.

· During this process, the oil also carries away the heat due to friction from the various components, and this heat is then carried away from the oil by the seawater running through the main lube oil cooler.

· The engine cylinders have their own lube oil system and pump as the oil requires to be alkaline, to combat acidity. The oil is injected through a set of concentric nozzles or quills arranged around the cylinder liner. This lubricates the surfaces between the cylinder wall and the piston rings; the oil control ring which is located lower down the piston and apart from the main set of compression rings scrapes off the excess oil, rather than allowing it to be burned in combustion.

· The temperatures and pressures of the main engine lube oil system are displayed on gauges within the main control console or above the engine controls, and should be maintained within the parameters laid down by the Chief Engineer/manufacturers. The engineers will normally mark these limits on the various gauges. I have used both thin strips of black tape and an indelible ink pen to achieve this. The watch-keeping engineer can then tell at a glance if there is a problem with the lube oil system.

· The control of the lube-oil temperature is vital to the efficient running of the main and auxiliary diesel engines; too high a temperature and the oil will lose its viscosity and, its lubricating qualities; too low a temperature can render the oil too viscous, making it ‘claggy’ or too sticky, leading to possible damage to the bearings, filters and oil circulating pump.

A typical lube oil system for a two stroke marine diesel is shown below;

Temperatures and Pressures to be Checked

We have seen how important lubricating oil is to an engine;

· Reducing friction.

· Preventing damage to moving parts.

· Dissipating excess heat.

It is imperative to keep the oil viscous and in good condition. This is carried out by the watch-keeping engineer who is responsible for maintaining a proficient engine-room watch especially, on lube-oil temperature and pressure, but also on the condition of the oil.

The diesel combustion process produces acids/sulphur residues; these in turn can escape between the piston rings and cylinder liners, getting scraped of with excess oil by the oil ring, thus making their way to the sump. This will contaminate the oil, degrading it to such an extent that it will require changing.

Also inherent of the marine diesel engine is cooling water leaking from the jackets due to a worn or damaged rubber seal ring between the cylinder liner landing and the engine block. The jacket cooling water will leak down the engine block, dripping unimpeded right into the lube oil sump. Watch keepers need to be aware of this and check the ‘tell tale leak detecter’ also that the sump oil has not become emusified two or three times a watch, using the dip-stick whilst checking for water in filters and centrifuge outlet.

We must also remember that not only should we depend on instruments to show us various temperatures and pressures but also to rely on our own sense of touch and smell is equally important, whether this is carried out by lightly touching the sides of the crank-case doors with the back of a hand, gripping the lube-oil supply pipes or by examination of the oil itself whilst rubbing a sample of it from the sump dipstick between the fingers when checking oil levels.

Maintenance is also important, oil must be changed regularly, the optimum differential pressure before and after the filters must be maintained and the filters cleaned as required. Any particles of white metal, dirt or water in the filters should be investigated immediately.

Most engines now have in-line lube-oil centrifuge system that will extract particles of dirt and moisture from the oil, helping to preserve the oils inherent properties.

A ship’s engine-room is a dangerous place to work, conceivably the most essential duty of the watch-keeping engineer is to sustain a constant lube oil temperature and pressure vigil, so that any rise in oil temperature or fall in oil pressure or a change in the condition of the oil is fully investigated by him.These conditions can be symptomatic of a bearing or other engine component running hot, and along with an oily mist detector alarm sounding can indicate an imminent serious explosion in the crankcase.