How would you move a gigantic oil rig from one place to another after installation or after dismantling? Or how would you transport a large passenger vessel with its hull damaged beyond vulnerability and exhausted of the very chances of mending it on-spot? Well, the first impression that enthuse us is the applicability of tugs or similar towing systems. However, everything has its own limitations and sometimes the situation demands that we bank on other options more inventively. Necessity is the mother of invention. So, one of the most tantalizing outcomes in the shipping world is the Heavy Lift Ships.By definition, they are specialized ships that carry out tedious heavy load in-taking operations that cannot be handled by normal or regular ships. They are segregated into two types : semi-submerging vessels capable of lifting another ship out of the water and transporting it; and vessels that augment or cater to heavy unloading facilities at inadequately equipped ports.

| Fig.1 Heavy Lift Ship carrying a cylindrical SPAR Platform |

A Brief History of Time

In the early stint of the previous century, most of the existing offshore technologies like rigs, platforms, oilwells, floating drydocks, drilling rigs,etc. were directly towed across the seas in what was known as “wet tow”. The mobilization was long, tedious,cumbersome and often posed risks of on-voyage damage. By the end of the 1960s,the towage companies realized that if they could manage a large barge-like vessel that would carry on themselves all these bulk items in what was conceptualized as the ” dry tow”, things could be easier. There was this ideal of carrying a floating cargo as a cargo on another floating object! All these had a bottom reaction” having a capability of a submergence stern resting on the seabed. In 1976, a renaissance was sparked off when the first heavy-lifter semi-submersible barge ‘Ocean Servant I’ entered the heavy lifting market. the induction of the buoyancy casings at the four corners enabled it to remain afloat and submerged without the need of bottom reaction. It had two 500-hp omni-directional propellers and was still self-towed. In 1979,the 1st self-propelled semi-submersible mighty barge ‘Super Servant’ came into the limelight.

It had a depth of 15 m , 6.5 m water level above the deck and had ballasting and de-ballasting features automated. Further down the timeline, in 1983, three ‘Mighty Servants’ with more advanced mechanisms and larger cargo-carrying capacity formed the most versatile class of the Heavy-lifters. A stark feature of these trio was the presence of three buoyancy casings which were removable. April 1985 saw the birth of two more of its breed namely, the ‘Dan Lifter’ and ‘Dan Mover’, which were rechristened Super Servants 5 & 6. By that time, technology had strode further with Heavy Lifters gradually acquiring the stake of major heavy lifting operations which also saw a further up-soar in the field of offshore like more semi-submersibles entering the deals. With doing away with stowage, mightier structures could easily be shouldered by these marvels and that too much easily by having the deck margin line absolutely parallel to the keel of the cargo. In April 1990, the ultramodern Heavy Lifter made by Russia ‘Transshelf’ created an upheaval in the revolution of modern Heavy Lifters.

Why heavy lift ships and how?

Heavy lift ships to be precise are hefty and ginormous special-purpose vessels that are about 3000 times the capacity of a blue whale! Sounds quirky, isn’t it? They miraculously have a lifting capacity of over 10000 tons. These ships have a large, wide and longish carriage deck which is mainly allowed to submerge below the water line and large bodies like oil rigs or whole ships are allowed to float on it or mounted on a dry dock. The alternation in freeboard and buoyancy is carried out by suitable ballasting and de-ballasting practices. The deck, henceforth comes out or remains submerged in water in such cases. Probably, you may wonder out of curiosity as to how the ship still remains unsinkable even after carrying such brawny loads. Well, we do give a quick glance at one of the most quintessential aspects naval architecture namely, draught, floatation and buoyancy .

A brief recall of Buoyancy and Displacement

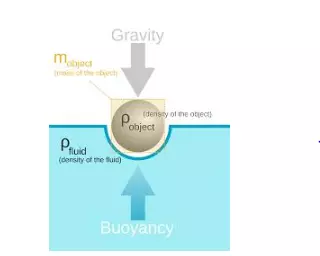

We all since our good old school days are not alien to a fundamental concept of Archimedes’ Principle. According to the statement, it is said that : “When a body is completely submerged in a fluid, or floating so that it is partially submerged, the body is subject to an upwardly acting buoyant force, which in turn is equal to the weight of the fluid displaced by the body.”

In other words, irrespective of the shape, size and other parameters of the body this upthrust or Buoyant force acts vertically upwards opposite to its weight. This force acts through the geometric centroid of the body and this particular point is christened as Centre of Buoyancy of the body. Though I do not delve much into the mathematical content and its diversities for different scenarios, one important thing we must confide is that not just a light paper but even the heavy lift ships weighing over 10000 tons obeys this classic principle thereby accounting for its habitability. Hence, if you do have a myth about these structural giants, do get rid of it! Even these hefty giants about 3000 times the size of a blue whale float like a normal paper-boat!Finding it a bit weird to be true? The phenomenon is the same old buoyancy governing all other marine vehicles. The displacement or the volume of water substituted by the submerged body accounting for the validity of Archimedes’ Principle is the main governing factor.So, heavy lift ships having a large scale displacement of the order of 10^5 square ms.have a large upthrust and the draught varies within certain limits depending on the temperature and salinity parameters of the water and also the load.

Fig. 2 Buoyancy and Archimedes’ Principle

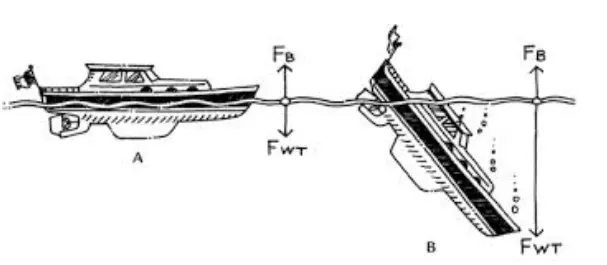

For high stability and to prevent heeling of the vessel sideways, stability is a quintessential aspect in such heavy lifting operations about which will be discussed shortly. However for a simple piece of reasoning that a ship does not lose its trim and tilt at one end, there should be a uniform weight distribution. Hence for a Heavy Lift Ship, the load is generally kept on the larger span of the weather deck which on many occassions remain submerged beforehand to handle larger displacements(and hence larger load capacities).

Fig. 3 Floating of a ship and its loss of floatation

Fig.4 Heavy Lift Ship carrying a smaller vessel.Has a submerged main

deck

Comments are closed