After a brief insight into the material properties commonly used, let us have a glance at the big and small structural members that make up a ship’s hull!

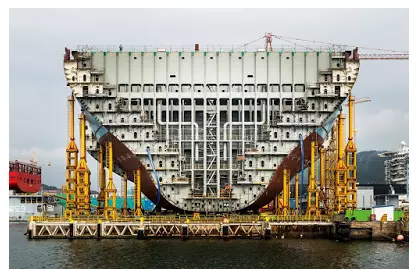

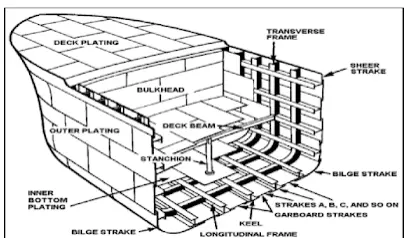

Fig. 5 General steel plating arrangement of the ship’s hull (Courtesy: wikipedia.org)

Plating:

They are the primary building blocks to any vessel just as bricks are to any house ! Right from the day when wooden vessels were made of wooden boards to the present day where steel/composite plating form the hull. Plates of varying dimensions or scantlings are used depending on the functionality, general arrangement and stress considerations. The final placement of the plates give rise to the structural truss which along with the outfitting and ancillary components give rise to the entire vessel form. Platings broadly referred to the outershell plating as well as the inner walls of the hull. They may also be found in the modified form of bulkheads or as components in decks and other outfitting. Platings prove their versatility in the role of taking up any shape as per the criteria, like round or being curved.

Well, a question which is definitely going to arise in your minds at this juncture: How are these mere plates joined or concatenated to give rise to the final shape?

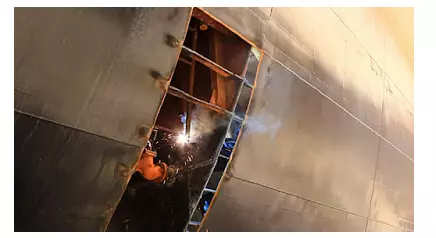

Fig. 6 Ongoing welding jobs within a ship’s hull

The answer is quite simple. Joining is very catalytic component in shipbuilding not only a ship’s production but also its subsequent productivity, performance and safety is highly dependent on the joining methods. The total length of structural joints in a large cruise ship is of the order of 400 -500 km! Even that too has an evolution like the ship itself.

Earlier,the method of caulking was used to make the seams in wooden boats and ships watertight, by driving fibrous materials into the wedge-shaped seams between boards.Till the World War era, it’s successor riveting was the chief technique employed which was the . The entire ship was exacted by joining cogs and nuts at every plate/board itself. This was a tedious task which made making of a ship very cumbersome and time-taking.

However, post-World War II, the modern techniques of Welding took over. Welding as we know is a safe,convenient and firm way of joining metals. Without delving into the details some of the various methods of welding involved are :

1. Electric-Arc Welding

2. Electro-Slag Welding

3. Shielded Metal Arc Welding

4. Submerged Metal Arc Welding

5. Gas Metal Arc Welding

6. Ceramic Welding

7. Laser Welding

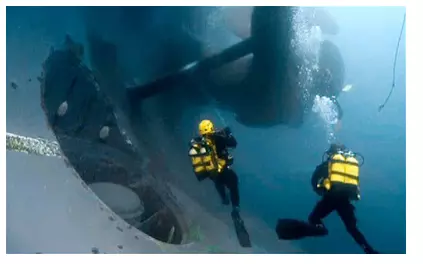

Fig. 7 Underwater welding repair of hull

While each of them have their own pros and cons, other methods of metal joining like Adhesive Bonding and Mechanical Joining Techniques are often used as well.

Keel :

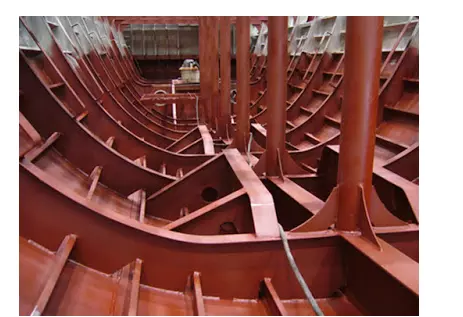

Fig. 8 Typical closeup view of keel network

All of you must be familiar with this term. It is often referred to as the backbone of any ship. It is the chief structural member in the form of the center plane girder that runs longitudinally from fore to aft, generally a beam around which the entire hull is supported. This could be worth saying that the entire hull grows from strength to strength about the keel at the base. The structural strength and integrity of the keel is a key determinant to the safety and the performance of the ship.

Maybe, this is why keel laying ceremony is celebrated in such an aura in any shipbuilding project!

The keel forms are divided into three principal types:

· Flat keel. The commonest form of every keel. A highly strengthened, flat beam is placed parallel to the ground. Most of the large ocean-going vessels and other bigger ships nowadays have this type of keel. This accounts for lower resistance, accurate draught; but is susceptible to grounding.

Fig.9 Keel laying of an old design flat-plate keel

· Bar keel: An old design of keel, still used in many smaller vessels and boats involves a rectangular cross-section flange poised over the bottom-most part of the hull. They are becoming rarer these days, thanks to its added weight problems which increase draft without increasing the displacement. However, having the unique property of jutting out below the main hull form closure ,bar keels are still alluded as a ready-hand solution to excess rolling.

· Duct keel is the hollow form of the keel floor in some ships, generally running from collision bulkhead to engine room bulkhead with the provision of allowing piping systems throughout its expanse.

Fig. 10 Inside a duck keel passage of an LNG carrier

Strakes:

They specifically refer to the bottom and side shell plating which are the supposed points of maximum stresses. Strakes are categorized as Bottom Strake, bilge strake and Sheer Strake. The bottom shell plating follows a unique system of nomenclature in almost all ships,i.e. in the form of successive alphabets with the keel as reference (e.g. A strake, B strake etc.).

The first stake in the order of appearance is also termed as Garboard Strake.

Similarly, the strake situated at the “turn of the bilge” is referred to as the Bilge Strake.

The upper-most strake near the deck edge is the Sheer Strake. It may be worth saying that as these are the critical points of high stresses, additional strengthening is provided to these plating to sustain high amounts of unpredictable loads.

Other members: Even if the ship looks complicated, its structural components are not that much complicated or massive as they might seem.The items are very basic like columns, struts, beams, flanges, angles, brackets and stanchions. Maybe these are not all. Small to negligible members exist in every minuscule of the vessel to give rise to the proper functionality of the structure. The nomenclature of all such members are different according to their role and location.Their role may be variant in the either of the following forms:

· Construction

· Support

· Strengthening

· Stiffening

Fig. 11 Diagram of all the basic structural parts of an arbitrary hull section

Although strengthening and stiffening are not exactly same, we simplify our topic of discussion by the convenience that the corresponding structures employed in ship construction are one and the same. We next a brief insight into the stiffening members.