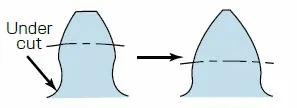

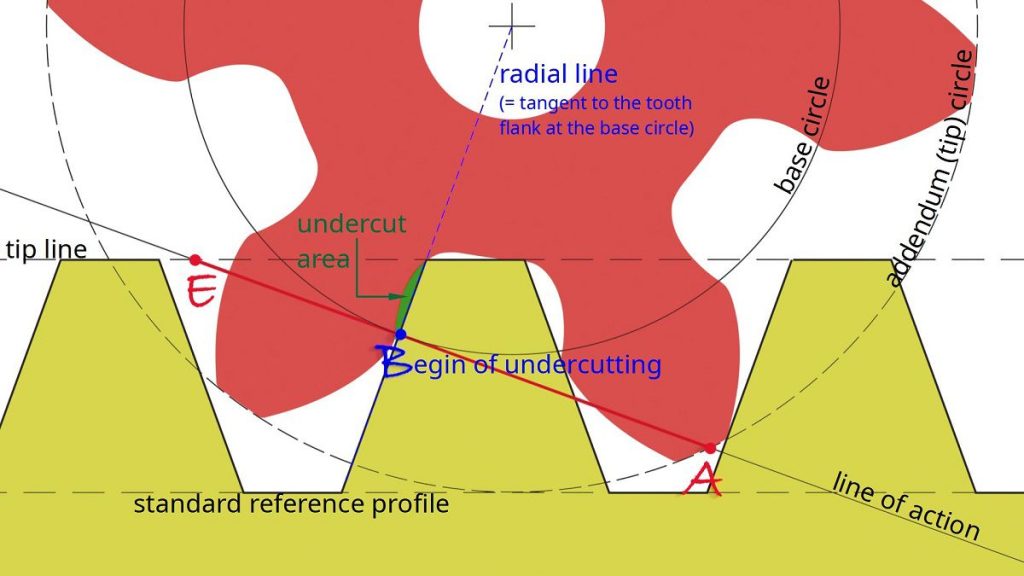

The undercut of gears is also called deeper cutting and indicates the phenomenon of cutting the root of the gear deeper than the involute tooth curve. This can happen when there is interference between a tooth cutting tool and a gear or between the two meshing gears. When the undercutting is large, the root of the gear becomes narrower and the tooth form becomes weak in its bending strength.

The main reason for undercutting to occur is, when cutting a gear with a small number of teeth (for standard gear with 20° pressure angle, number of teeth z = 17 or less), the tip of the cutting tool goes beyond the interference point.

To prevent undercutting without changing the number of teeth, a method called profile shifting is used. Profile shifting means changing the depth of the cutting tool and in the case of undercut, a positive profile shift is used. In this case, the root of the gear tooth becomes thicker. There is a limit to the amount of positive profile shift, and caution should be exercised since when the shift is excessive (x = +0.5), the tip of the tooth becomes pointed.

In addition, the examples of gear terminology related to undercut are involute tooth form, profile shifted gear, positive profile shift, etc.

Comparison with positive shifted tooth profile

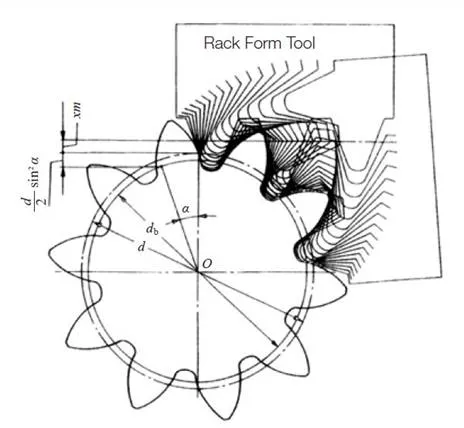

Generation of positive shifted spur gear

(α = 20 degrees, z = 10, x = +0.5)

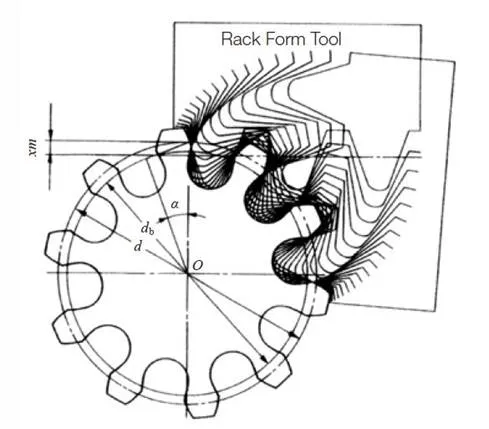

Generation of negative shifted spur gear

(α = 20 degrees, z = 10, x = -0.5)

Comments are closed