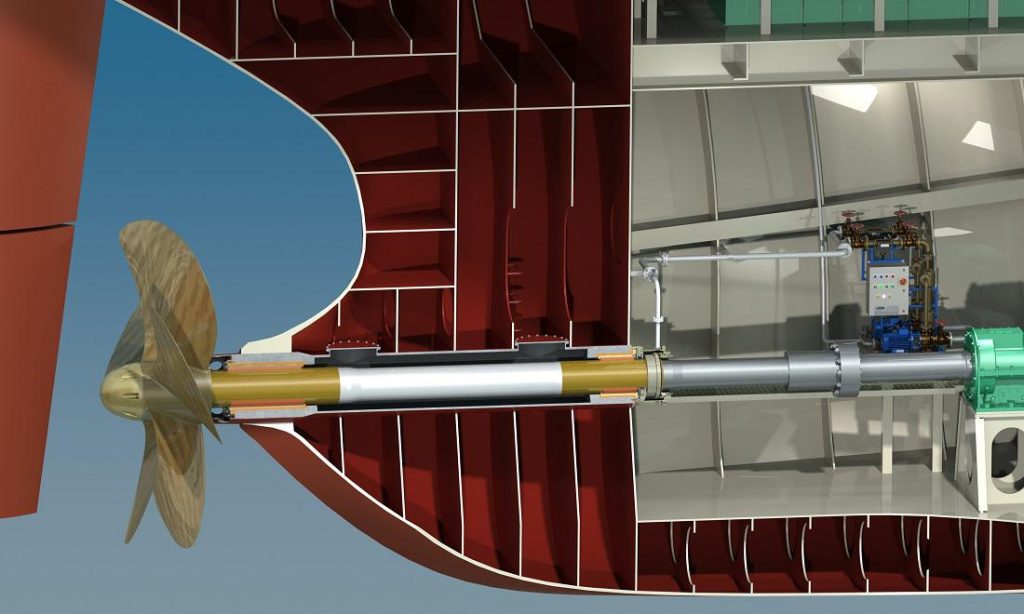

In a marine engine the function of the thrust block, propeller shaft, and stern tube are closely related, being responsible for the efficient transmission of the engine’s power to the propeller and ensuring the control of torque and propeller shaft alignment from the thrust block to the stern tube.

The thrust block is also known as the “Tilting Pad Bearing” or often the “Michell Bearing” after its inventor Anthony Michell, an Australian mining engineer.

Before these came along, ship’s engines were forever breaking down due to overheating thrust blocks. In those days (which were even before this old Irish Engineer’s day), multiple thrust collars were machined onto the propeller shaft with slots accurately machined into the thrust block to match these. Lubrication was supplied by a pump, but it was virtually impossible to obtain equal load on all the components, and hence the breakdowns.

Back to the present: the thrust block is situated just aft of the main engine and its purpose is to transmit the torque produced by the rotating propeller and shaft down into the ship’s structure.

The propeller shaft runs between the thrust block and the stern tube and is supported by a number of shaft bearings fitted along the length of the shaft. The stern tube contains supports and several seals for the propeller shaft as it passes through the ship’s stern before connection to the propeller.

The following sections examine the purpose of the thrust block, propeller shaft, and stern tube. We start by looking at the construction and operation of the thrust block.

Thrust Block Purpose and Operation

When I was at sea as a first tripper Junior Engineer, I well remember asking an old Aussie chief engineer about the purpose of a thrust block. He thought for a few moments, and then answered that if there was no thrust block the propeller and shaft would try to push the engine into the foc’s’le head. That was over forty five years ago, and it was not a bad analogy.

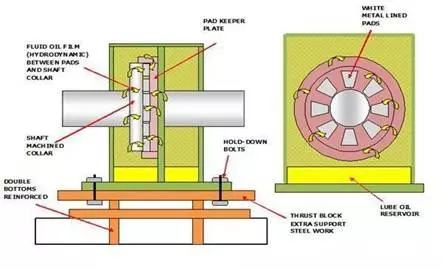

A more technical answer would have been that the purpose of a thrust block on a large marine engine is to transmit the torque produced by the rotating propeller through the housing hold-down bolts into the ship’s structure. (Remember this definition when sitting your marine engineer’s exams.)https://www.youtube.com/embed/xNLE8G3pC0k?controls=0&showinfo=0

The structure under the thrust block is reinforced with steel plates and I-beams above and inside the double bottom tanks or cofferdams.

The thrust block itself consists of a housing which contains a number of wedge-shaped white metalized pads with generous helical oil grooves cut into them. The pads are arranged and fixed around a steel support, holding them against a machined collar on the drive shaft.

The pads are prevented from overheating and premature wear by a fluid film of oil between them and the collar, with the oil supply being hydrodynamic (self-pressurized) due to the rotation of the drive shaft.

There is an oil reservoir in the bottom of the housing which may contain an oil-cooling coil through which seawater is circulated.

I have included a sketch of a Mitchell type thrust block of the type used when I was a boy at sea. However, it will not have changed much except perhaps the pads may now be PTFE lined.

Purpose and Operation of the Propeller Drive Shaft

The propeller shaft is bolted to the main engine flywheel, passing through the thrust block then along the shaft tunnel. Here it is supported by the shaft bearings before passing through the stern tube to drive the ship’s propeller.

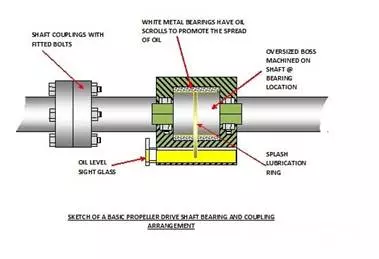

The shaft is manufactured from forged steel, complete with coupling flanges. It is machined leaving a larger diameter at the location of the shaft bearings; this section has to have a fine finish to run within the white metal bearing.

The shaft coupling flange faces are accurately machined and the bolt holes reamed to accept fitted bolts. They are bolted together using high tension bolting, which is tightened using hydraulic tensioning gear.

The supporting bearings are cast in two halves and are usually white metal lined. These have oil scrolls cut into them to distribute the splash lubrication. Nowadays ball bearing shaft supports are being used, but they have been reported as being quite noisy with a tendency to run hot.

A typical prop shaft white metal bearing with splash lubrication is shown here.

Purpose and Operation of Stern Tube

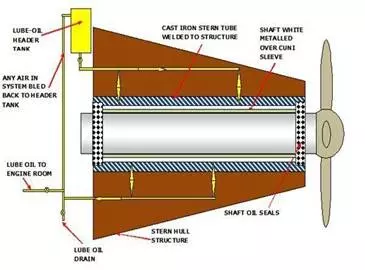

The stern tube is used to support and seal the propeller shaft as it passes through the aft hull. It consists of a cast iron tube welded into the stern frame. In the old days, the shaft inside the tube was bronze coated and run against a longitudinal bearing, which, when I was serving my time in Harland & Wolff Belfast, was made of narrow strips of a very hard wearing wood known as “lignum vitae.”

However nowadays, the propeller shaft has a CUNI (copper nickel alloy) liner shrunk onto it. Babbitt metal is applied over this and then machined, providing the bearing surface between the cast iron stern tube and the propeller shaft. This is lubricated and cooled by lube oil supplied from a gravity tank located under the aft peak. The propeller shaft has mechanical and/or adjustable gland seals fore and aft to prevent the ingress of oil to the sea and the aft bilge well.

Note:

There are several different arrangements of stern tube bearings. Some are similar to the one described, and some having additional water-cooled strut bearings fixed to the outside hull of the vessel, supporting the shaft right up to the propeller. (Notably on RN & US Warships.)

A typical stern tube arrangement is shown below.

Comments are closed