Everyone knows that a ship is propelled with the help of a propeller located at the aft of the ship. However, they may not know how the propeller is connected to the engine located inside the ship. A stern tube, situated at the aft of the ship, helps in this purpose.

The propeller is the only part of ship’s machinery, apart from the rudder, that is located outside the ship’s engine room. Have you ever seen the propeller of a ship and wondered how it is connected to the inside of the ship? Have you ever wondered where the shaft holding the propeller goes when it vanishes into the ship’s hull? If so, then you have come to the right place.

The propeller, a part of the propulsion system of the ship, needs a power source to rotate it. A marine diesel engine located inside the ship supplies the power to the propeller. Both the diesel engine and propeller are very heavy: locating them both at the same place inside the ship would disturb the ship’s stability. It is for this reason a stern tube along with a propeller shaft is used.

What is a Stern Tube?

The stern tube, as the name suggests, is a hollow tube-like structure at the stern or rear part of the ship. A ship needs a propeller to drive it forward against the waves. The propeller, located outside the ship, needs to be connected to the engine inside the ship’s engine room.

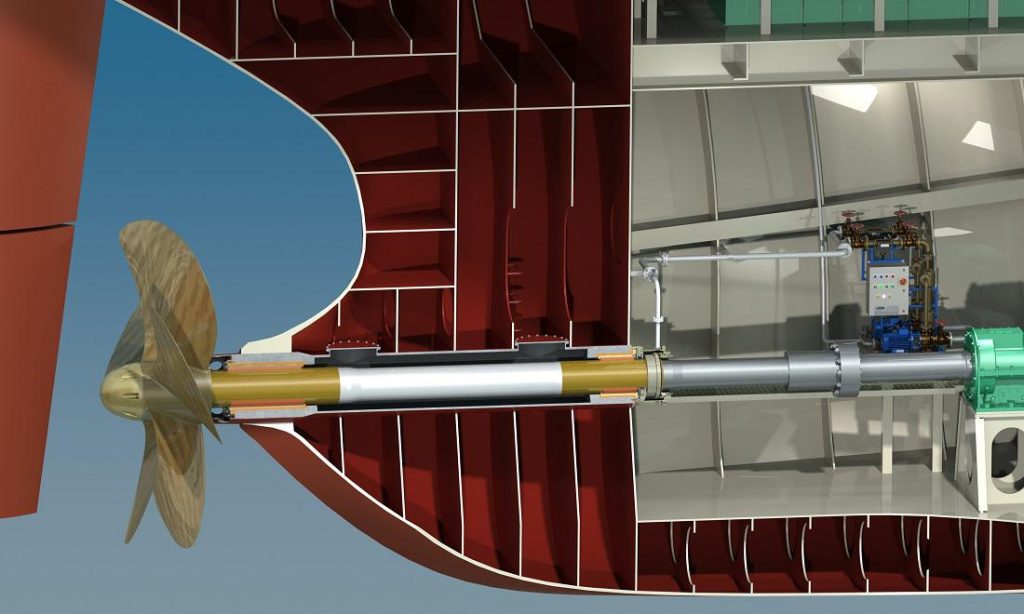

A long shaft known as the propeller shaft is used for connecting the ship’s engine and the propeller. The stern tube is a narrow hole in the hull structure at the rear end (aft peak) of the ship, through which the propeller shaft passes and connects the engine and propeller.

Inside the Stern Tube

The stern tube of a ship has a peculiar shape and arrangement for carrying the propeller shaft. As the shape of the ship is streamlined at the aft end, there is very little space to accommodate the propeller shaft arrangement. The stern tube is situated at the aft peak of the ship’s hull and the propeller shaft arrangement is also situated at the same level. The forward end of the stern tube is supported by the aft peak bulkhead and the aft end of the stern tube gets its support from the stern frame of the ship. Throughout the length, the shaft is supported by specially designed brackets and narrow floors inside the stern tube.

Stern tube Bearings and Glands

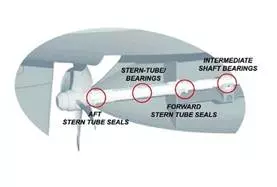

The total weight of the propeller shaft inside the stern tube is carried by the bearings known as the stern tube. The weight of the overall stern tube arrangement, along with the bearings is carried by the stern frame and the internal framing of the ship’s hull structure at the aft peak area. Moreover, there are generally two bearings inside the stern tube for supporting the shaft, located at both the ends. The main function of stern tube bearings is to allow an unrestricted and smooth rotation of the propeller shaft.

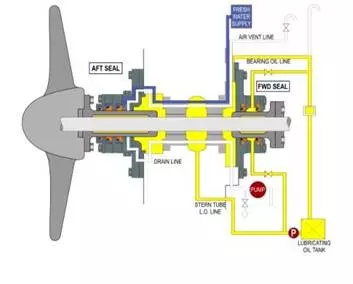

Apart from stern bearings, the stern tube also houses water and oil sealing glands known as the stern glands. The stern tube is a sensitive part of the ship where the sea water can easily seep inside. The stern glands thus seal the area between the stern tube and the propeller shaft. The glands are attached at the forward end of the stern tube and prevent the passing of seawater into the ship. The glands also prevent the leaking of oil from the stern bearings into the sea.

Seawater Lubricated Stern Tube Bearings

Editor’s Note: Thordon Bearings, Inc. contacted us to say we should include information on Seawater Lubricated, a method that is recommended by the EPA. As we were not familiar with this method, they graciously provided the following content and illustration to supplement this article.

Prior to the 1950’s, propeller shafts operated in water lubricated lignum vitae (a dense wood) bearings and used stuffing boxes as seals at the hull penetrations. The bearings however required regular replacement and the packings then available for the stuffing boxes were not ideal.

With increased environmental awareness and new legislation, there has been a return to seawater lubricated stern tube bearing systems. Improvements in water lubricated material technologies have resulted in greater choice of materials which can now offer improved and predictable bearing wear life with zero risk of oil pollution from the stern tube.

A seawater lubricated open system uses seawater as the lubrication medium in place of oil. The seawater is taken from the sea, pumped through non-metallic shaft bearings and returns to the sea. No stern tube oil is needed. There is no aft seal; only a forward seal to prevent seawater from entering into the engine room. Proven materials and new designs of non-metallic bearings now offer performance similar to metal shaft bearings.