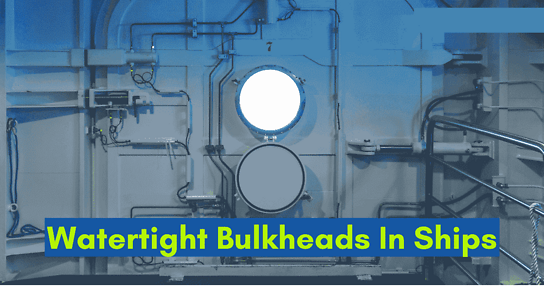

The safety of a ship in damaged condition is majorly dependent on the strength and integrity of its watertight bulkheads. There are a lot of factors that go into deciding the position of watertight bulkheads in a ship, and designing them structurally.

Watertight bulkheads are vertically designed watertight divisions/walls within the ship’s structure to avoid ingress of water in the compartment if the adjacent compartment is flooded due to damage in ship’s hull

The position of the bulkheads along the length of the ship is primarily decided by the results of flood-able length calculations during the assessment of damaged stability of the ship. However, once their positions are fixed, there are a lot of factors coming into play, for example: types of watertight bulkheads, their uniqueness based on their position, structural design, etc.

Collision Bulkhead

A collision bulkhead is the forward-most bulkhead in a ship. There are two factors that determine the position of a forward collision bulkhead. The final position of the collision bulkhead is so decided that it takes into consideration both the factors listed below:

Factor 1: Position based on flood-able length calculations.

Factor 2: Position based on the classification society code books. Most of the classification society rules have an allowable range of distance at which the collision bulkhead can be placed from the forward-most point of the ship’s hull. This distance is usually a function of the length of the ship and factors related to the shape of its bow.

Factor 3: Position based on SOLAS rule, which states that the collision bulkhead should be located aft of the forward perpendicular at a distance not less than 5 percent of the ship’s length of the ship or 10 meters (whichever is less). The distance must also not exceed 8 percent of the ship’s length.

However, the position of the collision bulkhead should be such that maximum cargo storage volume is achieved.

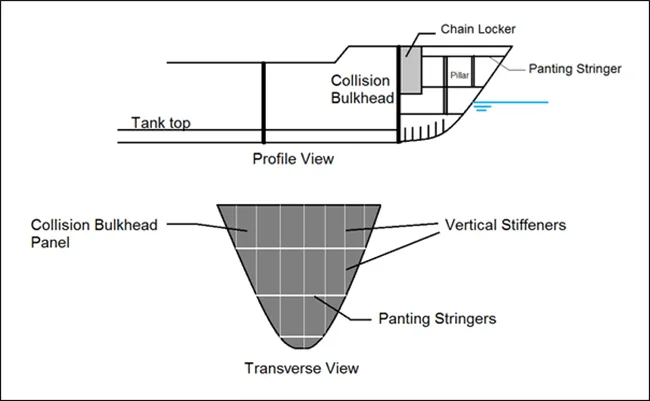

The collision bulkhead is a heavily strengthened structure, its main purpose being limiting the damage of a head-on collision to the part of the bow forward to it. To limit the damage to its forward region also means that the collision bulkhead is watertight bulkhead. It is usually vertically stiffened with sections of scantlings higher than those on the surrounding structures. It is also stiffened by triangular stringers of higher scantling, called panting stringers. Panting stringers are usually provided at every 2 meters from the bottom, forward of the collision bulkhead.

Figure 1: Collision Bulkhead (profile and transverse view).

As per SOLAS rules,

· The collision bulkhead must be watertight upto the bulkhead deck. A bulkhead deck is basically the deck level upto which all the watertight bulkheads are extended.

· For providing access to chain locker room and the forward part of the bulkhead, steps may be provided on the collision bulkhead. However, this must not violate Factor 3.

· There must be no doors, manholes, access hatches, ventilation ducts or any openings on the collision bulkhead below the bulkhead deck. However, the bulkhead can be allowed to have only one piercing below the bulkhead deck for the passage of one pipe to cater to the fluid flow to the forepeak ballast tank. The passage of the pipe must be flanged and must be fitted with a screw-down valve which can be remotely operated from above the bulkhead deck. This valve is usually located forward of the collision bulkhead. However, the classification society certifying the ship may authorise a valve aft of the bulkhead provided it is easily serviceable at any condition, and is not located in the cargo area.

· In case of ships having superstructures at the forward region, the collision bulkhead is not terminated at the bulkhead deck. It must be extended to the deck level next to the weather deck. This would ensure sufficient structural continuity and keep the shear forces within safe limits.

· If the collision bulkhead is extended above the freeboard deck, the number of openings on the bulkhead should be restricted to a minimum in order to ensure sufficient buckling strength. All the openings should be watertight.

Comments are closed