Gas shielded arc welding processes use a blanket of a gas, instead of flux, to provide insulation to the arc against the ambient environment. They are used extensively in shipyards to welding the comparatively lighter structures.

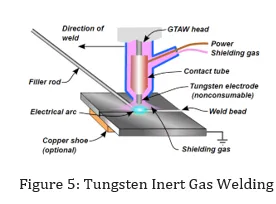

• Tungsten Inert Gas Welding (TIG): In this welding process, the arc is created between a non-consumable tungsten electrode and the parent metal plates. The tungsten electrode is surrounded by a nozzle that maintains a continuous flow of an inert gas around the arc. This inert gas shields the arc from oxygen, hence stabilising it, and preventing oxidation of the weld pool. A filler rod is introduced into the arc, which helps in the fusion of the two metals. The inert gas used in this process is usually Argon. TIG welding is preferred for plates of thickness usually less than 6 to 8 mm.

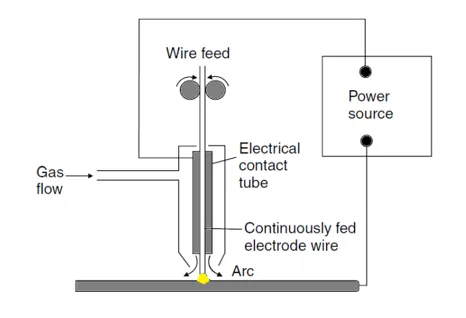

• Metal Inert Gas Welding (MIG): Metal inert gas welding is, in a way, an advancement on tungsten inert gas welding, where the electrode is a consumable metal wire.

Figure 6: Metal Inert Gas Welding.

The welding torch consists of an electrical contact tube which connects the electrode wire to the power supply. The electrode wire is continuously fed into the nozzle by a pair of driver rollers. It passes through the electrical contact tube. The flow of an inert gas is maintained into the welding torch through a separate line leading into the torch. It creates a blanket of inert gas around the stabilized arc.

Carbon dioxide is the most widely used inert gas for this purpose. MIG welding has been widely used in welding of aluminium deckhouses and spherical membrane tanks in liquefied gas carriers.

We will also discuss some of the other welding processes used in the shipbuilding industry for specialised purposes:

• Plasma Welding: This is similar to the process of TIG welding, except for the fact that the tungsten electrode is separated from contact with the plasma. Plasma is shot into the weld joint, which increases the temperature and provides shielding effect. This welding process is used for thinner metal sheets, most usually, in sheet-metal workshops in a shipyard.

• Laser Welding: Laser welding processes are used in advanced shipyards, and since this requires minimum heat input, the welding distortions (we will discuss this in detail soon) produced are minimised. The source of the laser in this process is either carbon dioxide or Nd:YAG (neodymium yttrium aluminium garnet) crystals.

• Thermit Welding: Thermit welding is more of a typical fusion process which is used to hold together large steel sections or forgings, for examples heavy sections of the stern frame of a ship. The heating in this welding process is achieved from a mixture of aluminium and iron oxide.

• Friction Stir Welding: This is a widely used process in shipyards, the source of heat being friction created between the rotating pin and the parent metal plates. The advantage of this welding process is its feasibility in the vertical direction, which makes it possible to friction weld but joints of side shells between blocks of a ship.