A ship floats in water during a major part of its lifetime except when it is in a drydock or when it is ultimately broken down into pieces. Since water is a good friend but a dangerous enemy, there are always chances of flooding of the ship and I am sure you remember what happened to the fateful Titanic on its maiden voyage. Hence ship safety is of ultimate importance and every care is taken at design and conception stage to ensure that various parts of the ship, especially the hull and the engine room are safe from flooding.

Water Tight Enclosures

Apart from strengthening the ship’s hull using stiffeners and frames, it is important to have water tight enclosures especially at places where it is important to have a door in a bulkhead for access purposes but it is necessary to maintain water tightness as well. There could be several such situations for example such as the shaft tunnel access from the engine room is via a water tight door.

This may seem to be a minor requirement but just imagine a ship stuck in rough waters due to weather conditions or any other damage due to grounding or collision and the importance of having water tight arrangement in such situations cannot be overemphasized.

Working of the Water Tight Doors

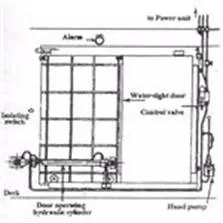

The concept and working of a water tight door in a bulkhead on board a ship can be best explained with the help of a diagram which is shown here. The various parts of the water tight door and bulkhead arrangement have been clearly labeled in the diagram and these include the following.

· Hydraulic cylinder which is necessary for mechanical operation of the door to open and close it.

· Hand pump which is necessary in case of failure of the mechanical system so that there is always a manual option for operation of the door.

· The necessary monitors and controls in the form of alarm and control valve which get activated for safety purposes.

· A remote switch from where the door can be operated as desired in case of emergency or any other situation where direct access is not possible. An indicator at this remote location which shows the status of the door as either being open or closed.

· Depending on the location and situation these doors could either open through sliding or like normal hinged doors. The material of construction of these doors is strong and durable material which could be either mild steel or cast steel. It is also required that these doors can operate without fail even when the ship is listed to around 15 degrees which is necessary to ensure safety in an actual emergency situation.

· In the actual manufacturing yard, the testing of the door is done either by applying high hose pressure of water and checking for water leakage at the other side or by submerging the door under the required pressure of water before it is actually fitted on to the ship.

· It is also worth noting that since cutting of the door in the bulkhead leads to reduction of strength, it is important to counter this effect by providing extra stiffeners and frames to reinforce the same, otherwise water may not get through the water tight door but might rupture the bulkhead itself which would defeat the very purpose of having a water tight door.

Comments are closed