Safety valve can be classified according to the amount that the valve will lift against the spring pressure.

· Ordinary Spring Loaded

· High Lift

· Improved High Lift

· Full Lift

· Full Bore Relay

The area of the bore of the valve governs the theoretical maximum amount of steam that can pass through a valve of any design.

The higher the valve lift that can be produced, the closer that the amount of steam passing between the valve and the seat will equal the maximum amount that can pass through the bore and the more efficient that the valve will be at dispersing the excess steam pressure. Here, Bore area = Lift area

Now, maximum effective lift (L) will be according to: Bore area = Lift area, L = D/4

Using the maximum effective lift as ideal, typical lifts for each type of valve are:

Ordinary Safety valve = D/24

High Lift Safety valve = D/16

Improved High Lift Safety valve = D/12

Full Lift Safety valve = D/5

Full Bore Relay Safety valve = D/4

Ordinary Safety Valve

It has lipped valve lid to increase the lift to D/24.

Valve lid is fitted with location wings to hold lid in alignment on the seat.

There is a clearance between valve lid and spindle guide bush D/4 to allow valve to lift fully on easing gear.

But, wings on valve lid can restrict steam flow and may cause jamming of the valve. Valve can jam in guide bush also. It has limited lift to D/24. Waste steam will used to accumulate above the valve and lower the spring force by acting downwards on the lip of the valve lid.

Now, this type of valve is rarely used.

High Lift Safety Valve

It has lipped valve lid and lid is fitted with location wings. It has separate piston and cylinder ring uses waste steam pressure to increase the lift to D/16.

But, wings on the valve lid restricts steam flow and it may cause jamming of the valve. Also, piston and cylinder ring can jam.

This type of valve has been replaced by the Improved High Lift valve.

Improved High Lift Safety Valve

It has lipped valve lid and of without wings. It has close fit lid on the spindle and it acts as a locator also. This is suitable for low and medium pressure boilers. These valves increase their lift over that of a simple spring loaded mitre value in two way: By specially shaped valve seat & By using waste steam pressure to increase the valve lift.

When the lid of the valve lifts, escaping steam is trapped in the annular space around the valve face; the resultant build-up of pressure acting upon the greater valve lid area causes the valve to lift very sharply.

This valve makes use of the waste pressure to increase the valve lift.

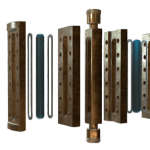

Full Lift Safety Valve

It’s a modern version of improved high lift safety valve. Hopkinson Hylif is a very famous design of this type of valve. It is winged valve and it doesn’t have floating ring.

When the valve lifts due to overpressure, it allows the escaping steam to act upon the full area of the enlarged face of the valve disc, lifting it up into the fixed guide sleeve. This prevents waste steam pressure acting on top of the valve and a vent is provided to keep the space between the valve disc and the spindle guide at atmospheric pressure. And, the waste steam pressure acting upon the face of the valve disc lifts it and helps to compress the spring.

Full Bore Relay Safety Valve

This type of valve consists of main and pilot control valves and both are linked with boiler pressure. When the excess boiler pressure has been relieved the pilot valve closes, so opening the ports and allowing the operating steam to vent to the atmosphere and this releases the pressure acting on the piston. The main valve is closed by the boiler pressure acting upon it. As there is no spring to oppose this force, the higher the boiler pressure the greater the closing load, just opposite to spring loaded valve.

Note:

Valve is continuously subjected to high temperature, so there is chances of valve seizure is more, that’s why operate every Saturday.

If any leak in steam pipe line, easing gear can be used to lift safety valve and to let the steam out.

Valve & valve seat, foreign particles stuck & deposited, operate easing gear and open safety valve, so that particles goes away due to steam passing.

Blow down of safety valve:

Opening at set pressure and closing slightly below the set pressure is called blow down of safety valve.

Blow down pressure can be adjusted by blow down ring (remove bolt & lift ring using screw driver).

Drain: No valve should be provided, so that nobody can shut drain. If no, drain water gets accumulated in valve and reduce the lift of safety valve.

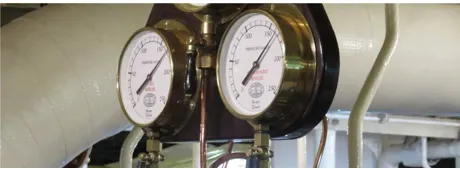

Setting of Safety valve:

· Take accurate displaying dial gauge.

· Take sufficient water in boiler.

· Shut the steam outlet valve.

· By-pass the High Pressure cut-out.

· Now, fire the boiler.

First put gauging tool in any one valve (Gauging tool valve is locked, so that it will not lift up)

Set the 3% working pressure in the other valve, by adjusting the compression nut.

After setting safety valve, measure distance between compression nut and top of the bolt.

Make a split collar (In lathe machine), and cut into two half.

Put in under the compression nut, so that anyone can’t adjust compression nut.