Threads are of prime importance, they are used as fasteners. It is a helical groove, used to transmit force and motion. In plain shaft, the hole assembly, the object of dimensional control is to ensure a certain consistency of fit. The performance of screw threads during their assembly with nut depends upon a number of parameters such as the condition of the machine tool used for screw cutting, work material and tool.

· Form measurement includes

· Screw thread measurement

· Gear measurement

· Radius measurement

· Surface Finish measurement

· Straightness measurement

· Flatness and roundness measurements

Screw Thread Measurement

Screw threads are used to transmit the power and motion, and also used to fasten two components with the help of nuts, bolts and studs. There is a large variety of screw threads varying in their form, by included angle, head angle, helix angle etc. The screw threads are mainly classified into 1) External thread 2) Internal thread.

Screw Thread Terminology

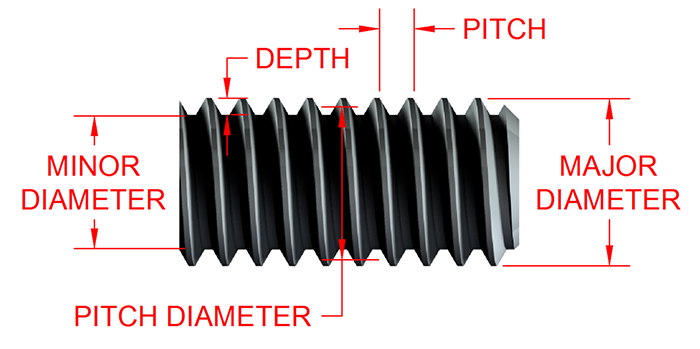

· Pitch

It is the distance measured parallel to the screw threads axis between the corresponding points on two adjacent threads in the same axial plane. The basic pitch is equal to the lead divided by the number of thread starts.

· Minor diameter:

It is the diameter of an imaginary co-axial cylinder which touches the roots of external threads.

· Major diameter:

It is the diameter of an imaginary co-axial cylinder which touches the crests of an external thread and the root of an internal thread.

· Lead:

The axial distance advanced by the screw in one revolution is the lead.

· Pitch diameter:

It is the diameter at which the thread space and width are equal to half of the screw thread

· Helix angle:

It is the angle made by the helix of the thread at the pitch line with the axis. The angle is measured in an axial plane.

· Flank angle:

It is the angle between the flank and a line normal to the axis passing through the apex of the thread.

· Height of thread:

It is the distance measured radially between the major and minor diameters respectively

· Addendum:

Radial distance between the major and pitch cylinders for external thread. Radial distance between the minor and pitch cylinder for internal thread.

· Dedendum:

It is the radial distance between the pitch and minor cylinders for external thread. Also radial distance between the major and pitch cylinders for internal thread.

Error in Thread

The errors in screw thread may arise during the manufacturing or storage of threads. The errors either may cause in following six main elements in the thread.

1) Major diameter error

2) Minor diameter error

3) Effective diameter error

4) Pitch error

5) Flank angles error

6) Crest and root error

1) Major diameter error

It may cause reduction in the flank contact and interference with the matching threads.

2) Minor diameter error

It may cause interference, reduction of flank contact.

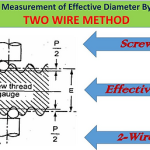

3) Effective diameter error

If the effective diameter is small the threads will be thin on the external screw and thick on an internal screw.

4) Pitch errors

If error in pitch, the total length of thread engaged will be either too high or too small.

The various pitch errors may classified into

1. Progressive error

2. Periodic error

3. Drunken error

4. Irregular error

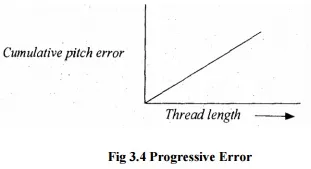

1) Progressive error

The pitch of the thread is uniform but is longer or shorter its nominal value and this is called progressive.

Causes of progressive error:

1. Incorrect linear and angular velocity ratio.

2. In correct gear train and lead screw.

3. Saddle fault.

4. Variation in length due to hardening.

2) Periodic error

These are repeats itself at regular intervals along the thread

Causes of periodic error:

1. Un uniform tool work velocity ratio.

2. Teeth error in gears.

3. Lead screw error.

4. Eccentric mounting of the gears.

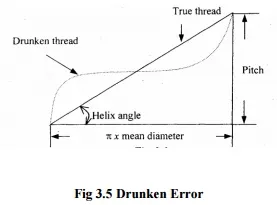

3)Drunken error

Drunken errors are repeated once per turn of the thread in a drunken thread. In Drunken thread the pitch measured parallel to the thread axis. If the thread is not cut to the true helix the drunken thread error will form.

Fig 3.5 Drunken Error

4) Irregular errors

It is vary irregular manner along the length of the thread.

Irregular error causes:

1. Machine fault.

2. Non-uniformity in the material.

3. Cutting action is not correct.

4. Machining disturbances.

Effect of pitch errors

· Increase the effective diameter of the bolt and decreases the diameter of nut.

· The functional diameter of the nut will be less.

· Reduce the clearance.

· Increase the interference between mating threads.