When it comes to choosing a ship fire extinguisher, we need to keep in mind different types of combustible material and fluids which are located in different parts of the ship along with the fire extinguisher reaction with the source of a fire. Based on the above-mentioned classification, portable fire extinguishers are classified and used according to the classes of fire as per IMO.

The portable type onboard fire extinguisher used in the marine or maritime setup is also known as plunger type fire extinguishers because of the plunger mechanism used to release the extinguishing agent. There are five main types of fire extinguishers used on ships:

1. Soda Acid Fire Extinguisher

2. Water Extinguisher

3. Foam Extinguisher – Chemical and Mechanical

4. Carbon Dioxide Extinguisher

5. Dry Powder Extinguisher

1. Soda Acid Extinguisher

A soda acid type fire extinguisher is recommended for putting out fires which involve burning of class A fires. The soda acid extinguisher can be found in the accommodation area of the ship.

Sodium bicarbonate (soda) and sulphuric acid are the prime components of the extinguisher. They combine to form a chemical reaction to produce carbon dioxide gas, which is used to smother the fire.

Soda acid fire extinguisher diagram:

The arrangement of the extinguishers comprises of a container which holds the sodium bicarbonate solution. A small glass bottle (phial) containing sulphuric acid is placed below a plunger mechanism, which is covered by a safety glass along with a screw and cap at the top.

When the plunger is struck hard, the glass bottle breaks, resulting in mixing of acid and soda, a chemical reaction takes place which produces carbon dioxide gas.

The carbon dioxide gas pressurises the space above the liquid (used for extinguishing the fire) and forces it out through the internal pipe of the nozzle.

Note: As the CO2, which is used in soda acid fire extinguisher, may create a toxic effect in confined spaces, Soda Acid Extinguishers are now banned on ships.

2. Water Extinguisher

To counter the A-Class fire, portable water type fire extinguisher of 9Ltr are used. The outer container is filled with water and fitted with a CO2 Cartridge (inner container) which forces the water out of the container with pressure.

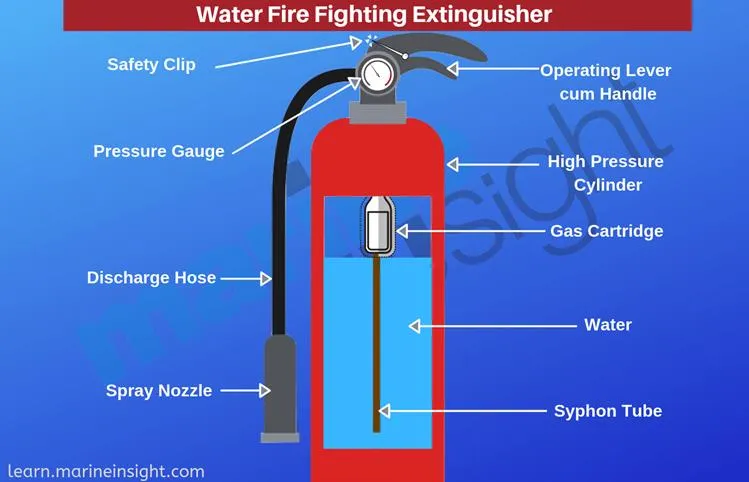

Water type fire extinguisher diagram:

To operate the extinguisher, first, the safety pin/clip is released. When pressure is applied on the plunger, the CO2 cartridge ruptures and forces the water out of the extinguisher.

3. Foam Extinguisher – Chemical and Mechanical

Foam extinguishers are used to extinguish Class B fires and are located near flammable liquids. There can be two types of foam fire extinguisher depending upon its contents-

· Chemical foam type fire extinguisher

· Mechanical foam type fire extinguisher

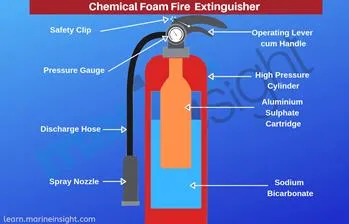

Chemical foam extinguisher – The chemicals used in this foam type fire extinguisher are sodium bicarbonate and aluminium sulphate. The main container is filled with sodium bicarbonate, whereas the inner container is filled with aluminium sulphate.

Chemical foam extinguisher diagram:

The inner container has a cap at the top which is kept in place by a plunger.

The plunger is turned to release the cap and the extinguisher is then inverted for both the chemicals to mix. Carbon dioxide is produced from the chemical reaction which pressurizes the container from inside and forces out the foam.

This type of portable foam fire extinguisher chemical equation is shown below:

Al2 (SO4)3 + 6 NaHCO3 -> 2Al (OH) 3 + 3Na2SO4 + 6 Co2

Note: Chemical Foam Extinguishers are now banned on ships because of the poisonous effect which the gas can create.

Mechanical foam – This extinguisher type also consists of two containers- the outer one is filled with water, whereas the central one has carbon dioxide charge and foam solution. The mechanical foam fire extinguisher uses a long hosepipe connected to the dip tube inside the internal structure of fire extinguisher which allows it to use the foam portable fire extinguisher upright.

mechanical foam type fire extinguisher diagram showing different foam extinguisher parts:

The central container has a plunger mechanism at the top which when depressed releases the carbon dioxide and allows foam and water to mix.

The foam and water come out of the nozzle, creating mechanical foam. This extinguisher is operated in an upright position.

4. Carbon Dioxide extinguisher

Carbon dioxide extinguishers are mainly used for class B or class C fires. They are not used for accommodation areas and confined spaces because of the gas used in lethal. These are widely used as engine room fire extinguisher.

CO2 type fire extinguisher diagram:

Carbon dioxide is stored in liquid form under pressure. A central tube acts as an outlet for carbon dioxide gas. A plunger attached to a bursting disc at one end and a trigger at the other is used to release the carbon dioxide gas. The liquid changes to gas as it comes out of the extinguisher through a hose.

5. Dry Powder Extinguisher

Sodium bicarbonate powder is used to extinguish almost all types of fires. It is mainly located in the engine room and near electrical equipment.

Dry powder extinguisher contains sodium bicarbonate powder in the outer container.

DCP extinguisher diagram:

A small container with carbon dioxide is placed beneath the plunger mechanism.

When the plunger is pushed, it releases the carbon dioxide gas, which in turn forces the dry powder out of the discharge nozzle.

Semi-Portable Fire Extinguishers:

The semi-portable type of fire extinguisher is higher in capacity and weight than the portable ones. They are considered to be the second line of defense in case the portable fire extinguisher fails to stop the fire exposure.

As they are heavier to lift, it is provided with a wheel-trolley arrangement which can be dragged to a nearby fire location. These can be a semi-portable foam fire extinguisher or semi-portable DCP type fire extinguisher.

These extinguishers are kept onboard on that location which has a higher risk of fire. E.g. The semi-portable type fire extinguisher is located near the boiler and incinerator in the engine room and also in the galley. The galley fire fighting system in a ship may include a small CO2 fixed firefighting setup apart from the portable galley fire extinguisher.

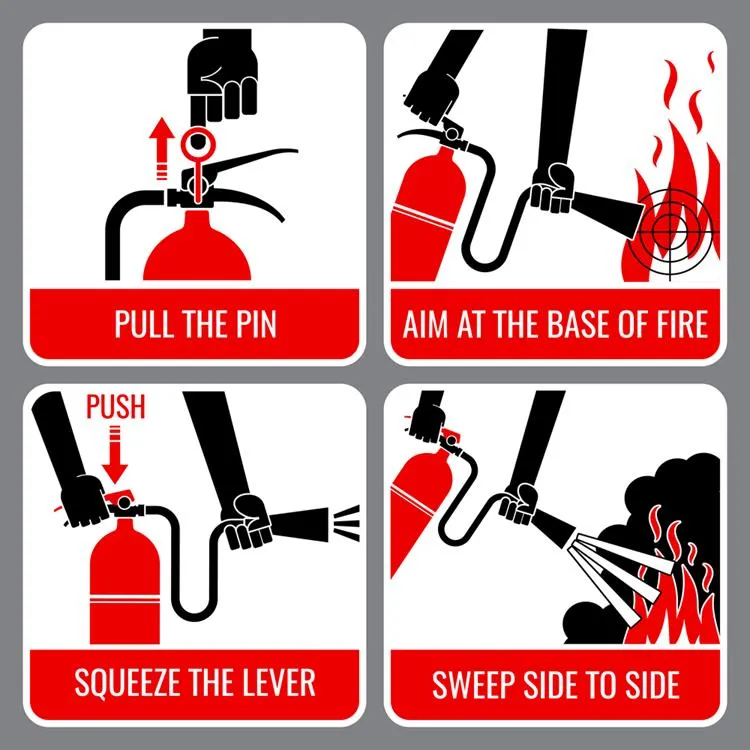

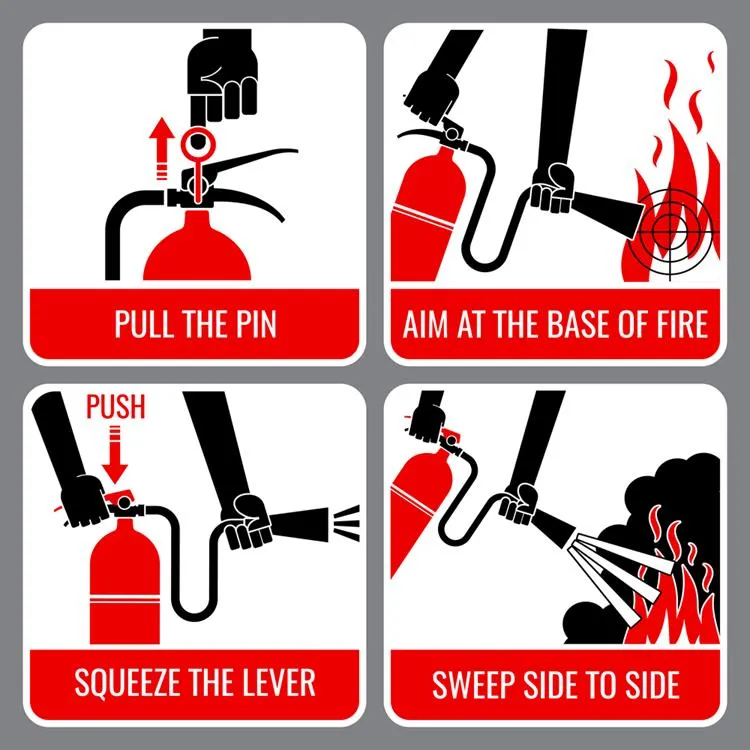

Using a Portable Fire Extinguisher:

The below diagram shows the operating procedure for a portable fire extinguisher:

Maintenance of portable fire extinguishers on ships:

· The portable extinguishers are a type of pressure vessels and should be routinely checked for leakage etc.

· The operating mechanism of the portable fire extinguishers should be regularly checked (where possible) every 3 months.

· The vent holes to be checked for clearance.

· All the cap threads should be lightly greased. There are holes provided in the screw on caps to release any excess pressure. Ensure these holes are clear.

· The plunger should be checked for free movement, and any missing or damaged plunger should be replaced.

· Depending upon the types of fire on board ship, the flag state and class requirement accordingly determines the number, types, and locations of these portable fire fighting extinguishers as per SOLAS.

· The ship’s officer must ensure all the fire fighting equipment, including the fire extinguishers, are always in the state of readiness. Any problem or defect in the fire extinguisher to be reported immediately to the master.

· Check all the markings on portable fire extinguisher are visible including the inspection dates.

· The recharging of the extinguisher to be done as per the instruction supplied by the manufacturer only.

· For DCP, invert the extinguisher once in a while to ensure the powder inside it is agitated.

· Hydraulic tests of all the extinguishers with propellent cartridges to be performed at an interval, not more than 10 years.

Comments are closed