Alternate Maritime Power or AMP is an anti-pollution measure which helps in reducing air pollution generated from diesel generators by using shore electric power as a substitute.

AMP is used when the ship is halting at a port so that the engines of the ship (working on diesel) do not need to be used unnecessarily. This, in turn, helps in reducing the emissions from the ships by a great margin. This process is also called cold ironing

The process of cold ironing can be explained with the help of a few simple steps:

· When the ships are being loaded or unloaded in a port or dock, alternate marine power is supplied to them

· This is done so with the help of supply cables that are plugged into an electricity supply board in the port on one end and to the ship’s power supply board on the other

· The process is called cold ironing because, in the olden days when the ship’s mainframe engines used to be rested, they used to get cold while the power was being transferred in this manner

· The process leads not just preservation of the marine ecosystem but also contributes to lesser usage of diesel and other oily power supply materials

· AMP provides power for lights, refrigerators, air-conditioners and other equipment on a ship

· The power coming from the shore can be from a separate power generation unit or from the power plant supplying power to the port city or town.

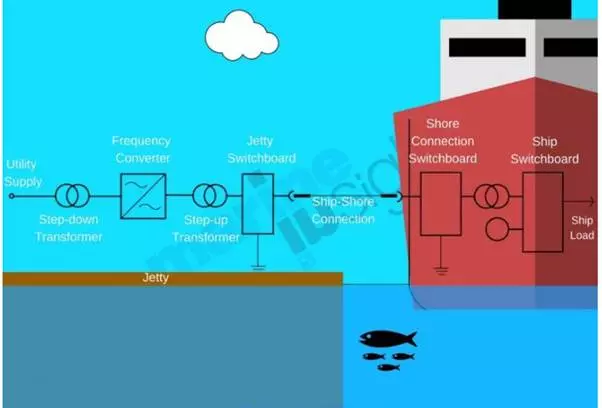

At present, there are four different variations in the AMP that is provided from the port to a ship or a tanker. The same can be listed as follows:

· 11000 Volts of AC (Alternate Current)

· 6600 Volts of AC

· 660 Volts of AC

· 440 Volts of AC

As different countries around the world are becoming more aware of the clean environment, some ports like Los Angeles Port have already taken initiatives to ensure the environmental protection by reducing air pollution.

For e.g. ships berthing at Los Angeles Port or other California ports are required to stop idling the engines (low load operation) and transfer the power source to a land base. This allows the ship to switch-off its generators, thereby giving a significant reduction in noise and air pollution.

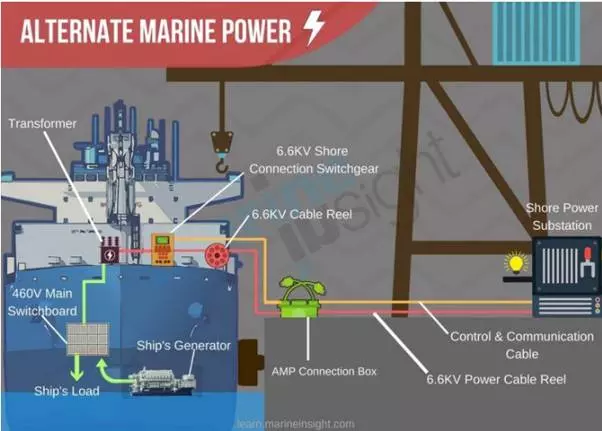

The AMP system comprises major components such as – Cable Reel, Reel Control Centre & Pendant, Amp Connection Box, 6600v Shore Panel, Transformer, Main Switch Board, Amp Control Panel.

Let’s understand each of them below:

Cable Reel

The cable reel is a ship-mounted reel that is designed to handle electrical cables that connect the ship to a land-based power source when moored at a port. The cables act as conduits for electrical power and fibre optic communication.

Once the cables are connected, the cable reel reels up for certain seconds every few minutes (according to the design) in order to recover any slack that results from ship movements and wind by changing to automatic mode. The cable reel is grounded to the hull with the help of a grounding bolt.

Reel Control Center & Pendant

The reel control centre is an IP enclosure, which incorporates the electrical switchgear required to control the cable reel operation. A pendant controller with 4 functions acts as the operator interface, and the indicator lamps mounted on the door of the enclosure provide the feedback.

AMP Connection Box

AMP connection box is the place where shore cables coming from the other end of the cable reel are connected. They are two in number, one at port side and other at the starboard side. The box is used for changing the connection of plugs to the mooring side. Usually, the plugs maintain connection except during maintenance.

6600V Shore Panel

This panel is a switchgear for receiving electric power from the shore. A vacuum circuit breaker (VCB) and an earthing switch (ES) for high voltage are equipped herein, along with a protection relay for high voltage.

Transformer

When AMP system is in use, the shoreside power is transformed from the high voltage to low voltage, and the power is supplied to the main switchboard (MSB).

Main Switchboard

AMP panel in the main switchboard (MSB) can operate by an automatic or manual operation to synchronise with the shore power without leading to blackout situation.

AMP Control Panel

AMP system is controlled by this panel. It has a condition monitoring function.

Fibre Optic Communication

In some AMP systems, fibre optic communication is used between shore and ship. A fibre optic cable goes along inside the cable for the purpose of communication. Clean fibre optic components are a requirement for quality connections between fibre optic equipment. Any contamination in the fibre connection can cause a communication failure. Even microscopic dust particles can cause a variety of problems for optical connections. By comparison, a typical human hair is 50 to 75 micrometres in diameter and is about 8 times larger than a dust particle. So, even though dust might not be visible, it is still present in the air and can deposit onto the connector. In addition to dust, other types of contamination must also be cleaned off the end face.

Cable Reel Overview

Cables: The cables act as conduits for electrical power and fibre optic communications. They are specifically designed for reeling purposes, having exceptional flexibility and high tensile strength. A special sheathing compound provides high resistance to the harsh marine environment.

Drum: The drum is used to store the cables. The internal diameter of the drum is selected to meet the minimum bend radius requirements of the cable and to ensure an optimal relationship between reeling torque and cable tension. The external diameter of the drum is selected to ensure that the full cable length can be accommodated.

Guide: The guide acts to provide a relatively frictionless path for the cables between the drum and the side of the ship. It consists of a number of rollers arranged in a radius that is greater than the minimum allowable bend radius of the cable.

Collectors: The collectors facilitate the transmission of power and data between the rotating reeling cable and the fixed machine cables.

Hydrodynamic Drive: The Hydrodynamic drive is a specially designed reduction gearbox that incorporates an oil-immersed torque-regulating clutch. Torque is produced by shearing oil between two rotating metallic disks. The amount of pressure acting at the interface, and therefore the torque output, can be easily adjusted over a large range.

The concept of AMP has come a long way. In the initial days, cold ironing was used just as a recharging accessory for the tankers. However, seeing that the usage has widened and grown so much in these past few years, it can be assumed and hoped that alternate marine power will become a tool far more vital and necessary than what it is today.

Ship/Shore Changeover Procedure

There are two methods of changeover – an automatic change and a manual change.

As for an automatic change, a synchronization and load shift are performed automatically. A manual change can perform a synchronization and load shift by manual operation. Automatic and manual synchronous change is performed by running of only one generator. It is necessary to decrease the load and obtain changeover at minimum load.

MP Connection Procedure

· First, confirm that the generator is on the minimum load possible and voltage is around 440V. To lower the cable guide, first connect the operation remote to the reel, after which, the reel is ready for operation. The Power On indicator lamp on the Reel control centre will light up.

· Press up and hoist up the cables from their parking position. The reel will stop rotating automatically when the upper limit is reached.

· Direct the cables to the cable reel guide and prepare it for lowering by pressing down button.

· Press down button and lower the cables, keep a check there is no snag, twist or turn. Keep lowering the cables until it reaches the port personnel on the jetty.

· The port personnel must pull the cables towards the connection box while the cable is still unwound, then remove the protective caps on the end of the cables and connect them to the shore terminal. The cable plugs should be connected according to colour coding and should be connected correctly.

· Once the cables are connected, change the selector switch to automatic mode. The reel should then automatically operate in order to recover any slack that results from ship movements and wind.

· You will have to confirm with shore personnel whether fibre optic communication will be used or not. If yes, then you will have to turn on fibre optic switch inside main switch mode. If no, then communication can be done via VHF or Phone.

· Try out the emergency stop on AMP control panel. The pilot ready lamp should turn off confirming positive working of the emergency stop.

· Try out emergency stop on cable reel control panel. The pilot lamp should turn off confirming positive working of the emergency stop. Reset from the panel.

· After completion of all tests, you are ready to turn on the VCB and close the breaker. Confirm with the shore personnel that VCB can be closed and upon confirmation, close the VCB

· After closing the VCB, you are ready for synchronisation. This can be done automatically or manually. First, you need to check shore receiving parameters to check if they are all correct and in range. For automatic synchronisation, press synchronise on the AMP control panel and the shore power will synchronise with ship’s generator power. For manual synchronisation, you can synchronise with synchroscope method or three bulb method

· Once shore power has synchronised with the ship’s generator power, you can offload the ship’s generator so that all the load can be taken by shore power. Once the generator is offloaded and the breaker is open, the ship can be said to be running on alternate maritime power.

The shore charges for the power it supplies in KWH. So, it is always advisable to have minimum load possible when on alternate maritime power so that costs don’t increase significantly.

AMP Disconnection Procedure

· Disconnection procedure is reverse of connection procedure. You have to take shore supply offload and ship’s generator on-load by following these steps

· Start ship’s diesel generator and take it on-load by synchronising it with shore power automatically or manually. After the generator is on-load successfully, offload the shore power by opening the VCB. Open the VCB only after confirming with shore personnel.

· Once the AMP VCB is open, the ship is running on ship’s generator and no more cold ironing. Cables should be made ready for disconnection.

· Change the selector switch to manual mode and press the DOWN button to slacken the cables

· The port personnel must disconnect the plugs & sockets and re-fit the covers.

· Press the UP button to retrieve the cable. Avoid dragging the plug protection covers along the jetty, it is preferable that these are manually handled in order to reduce wear.

· Continue pressing the UP button until the upper limit is reached. With the assistance of another person, press the down button and guide the plugs into the parking zone. Turn off reel control centre.

However, even as cold ironing has a lot of advantages, there are quite a few disadvantages to the process. The crucial disadvantages can be explained as follows:

· Problems pertaining to cost. The consumption of electricity can be enormous owing to the size of the ships and tankers. This factor is the primary negative contributor to AMP

· Every port and harbour where such ships halt for the loading and offloading of cargo and thereby for the cold ironing process will require a huge investment to set up the equipment for AMP

· Even certain ships are not compatible and suitable for the process of alternate marine power. The cost of equipping these tankers with the right kind of AMP gadget will also require an enormous investment

· The reduction in pollution occurs only when the ship is stationary. When the ship is actually in the water, then because of the usage of conventional engines, pollution will still spread in the marine atmosphere.

Comments are closed