Dozens of motors are used on board ships for a variety of purposes in both deck and engine departments. Each of these motors has its dedicated starter panel, which is used for the switching purpose i.e. On and Off operations. Like any other machinery system, these motor starter panels also need regular maintenance to ensure smooth motor operation

What is Starter Panel Routines?

Motor starter panel routines include inspection and maintenance of moto ’s starter panel.

· Starter panel routines mean inspection and cleaning of contactor’s (the switch inside the starter panel box controlling the on and off of the motors) contacts

· Checking of connections in the starter panel

· Cleaning of the complete starter panel

· Checks in the terminal box on the motor for loose connections

· Visual inspection of overall starter panel

Why Starter Panel Routines and Maintenance are Important?

Every time we switch on the motor, the contacts in the panel get energized as electricity flows through the contacts (high current flows during starting).

At the time of on/off of the switch, a spark is generated in the contacts for a fraction of seconds. In case of poor contacts, this spark will damage the same, leading to pitting/scoring marks in the contacts along with carbon deposits on the contact surface.

Safety Measures to be Followed While Starting Motor Starter Panel Routines:

1. Switch off the main power supply from the circuit breaker

2. Take out the main fuses in the starter panel, and if required control fuses as well

3. Put the lock out tag

4. Inform the engineer who is in charge of that particular machinery

How to Carry Out Motor Starter Panel Maintenance?

· Open the motor starter panel and the contactors. This would need special ‘T’ type key, which is found with the electrical officer. The panel can be opened when the breaker is switched off

· Take out the moving contacts and the arc huts. Keep a very fine emery paper, good evaporative type contact cleaner, and a clean cloth for cleaning and maintenance purpose

· Mark the moving contacts from where it was removed; clean the fixed and moving contacts, and the arc huts

· Fix the contacts as per the markings and check for any lose connections inside the panel

· By visual inspection we can identify the contact’s condition. T k out the contact, clean it by a smooth cloth or a very fine emery paper and measure the contact’s width by Vernier calliper at 3 different places. Note down the values

· Simultaneously take a same type of new contact, measures and note down the width values measured in 3 different places. Now compare the values to find out the actual contacts condition

· If difference between the values is bigger, replace the contact with a new one (same type)

· Also make sure that the measured value of a single contact must be same on both sides in both moving and fixed type contacts, otherwise there is a high possibility of sparks generation

Important Points

If cleaning of deposited carbon is not carried out at regular intervals, it can lead to two main issues:

· A poor contact – which will increase the spark amount and frequency

· Increase of fire hazard – The deposited carbon will act as fuel for fire

Checking for Loose Connections

Inside the motor starter panels, check should me carried out for loose connections to avoid short circuit, spark or accidents.

How to Check for Loose Connections?

· Tighten the loose screws using a Screw driver, if found any

· Using your hand, try to pull out the wires slowly. If any wire comes out completely or more than it should, take it out and reconnect

· Check the insulation of the connected wires, as because of aging and sparks there is a possibility of damage to the wires

Cleaning of the Starter Panel

· The motor starter panel should always be maintained clean to reduce fire hazards

· Clean the whole starter panel by a wet cloth and use brushes where hands cannot reach

· A vacuum cleaner can be used to remove dust

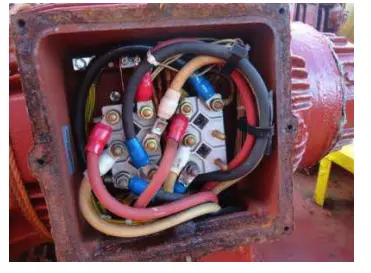

Checking the terminal box of the motor

Motor is a dynamic machine, and thus there will always be vibrations. This leads to loose connections in the terminal box of the motor.

· Open the terminal box of the motor by loosening the nuts

· Check the tightness of the connection by shaking the wires and use the correct size spanner to tighten the connections

· If there are any loose connections, it will lead to sparks in the terminal box causing fire in the motor

· Short circuit is also possible because of a loose connection

After the maintenance is done on the motor starter panel:

· Remove the lock out tag

· Insert the main and control fuses in the starter panel

· Switch on the main power supply from the circuit breaker

· Inform the engineer who is in charge of that particular machinery

· Start the machine and check the starter panel if there is any abnormal sound.

Comments are closed