Blackout is one condition each and every mariner is familiar with and also afraid of. It is one situation everyone on the ship is terrified of as it brings the whole ship and its operations to a standstill.

Understanding Blackout Condition

Blackout condition is a scenario on a ship, wherein the main propulsion plant and associate machinery such as boiler, purifier and other auxiliaries stop operating due to failure of the power generation system of the ship – Generator and alternator. With advance technologies and automation, preventive measures are provided to avoid such blackout situations by means of auto load sharing system and auto standby system, in which, the generator set that is running in parallel or standby comes on load automatically when the running diesel generator fails.

What to Do in Case of a Blackout?

In case of a blackout following precautions and actions should be taken:

· Never panic in such situation, be calm and composed. Emergency generator will restore the power in no time

· Inform officer on bridge briefly about the condition

· Call for manpower and inform the chief engineer

· If the main propulsion plant is running, bring the fuel lever to zero position

· Close the feed of the running purifier to avoid overflow and wastage of fuel

· If auxiliary boiler was running, shut the main steam stop valve to maintain the steam pressure

· Find out the problem and reason for blackout and rectify the same

· Before starting the generator set, start the pre- lubrication priming pump if the supply for the same is given from the emergency generator; if not, then use manual priming handle (provided in some generators)

· Start the generator and take it on load. Then immediately start the main engine lube oil pump and main engine jacket water pump

· Reset breakers and start all the other required machinery and systems. Reset breakers that are included in preferential tripping sequence. (Nonessential machinery)

Seafarers require both skills and patience to tackle a situation like blackout, especially when the vessel is sailing or manoeuvring.

However, the best way to tackle such situations is to be calm and composed; and to know your engine room and machinery very well in advance.

Electrical Relay Maintenance on Ships

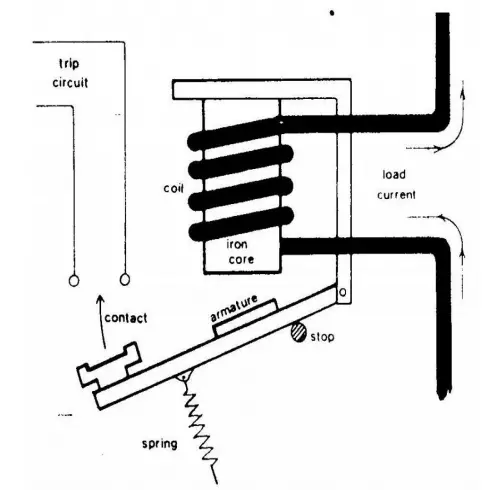

A relay is an important electromechanical safety device in ships electrical circuit and is normally used to open the faulty circuit from the main supply when any kind of electrical fault occurs.

A relay is fitted in the Main and Emergency switchboards of the ship as a protective device.

Relay has to be kept operational and healthy at all times, else at the time of fault if the relay does not operate properly, the whole system may suffer loss of power or damage. The most common application of relays is for overload and short circuit protection.

A ship engineer or electrical officer has to make sure that the relay is efficiently in operation and the maintenance is carried out on the same as per schedule. If during inspection, the relay is found out to be defective it must be replaced immediately with a spare one.

A simple electromagnetic relay will get activated when the magnetic effect of the iron core is sufficiently increased by the excess or high current in the coil, which will attract the iron armature held against the spring force to trip the circuit.

A brief maintenance procedure for relay is given as follows-

· Checks to be carried out on relay contacts for damage due to arcing

· Polish the contact with emery paper to remove rust and deposits

· Check the closing linkage for free movement

· Check the continuity of the contacts with multimeter

· There are arc chutes provided to quench the arcing. Check for burnout of the same

· Check the tension of the spring

· Open circuit and short circuit tests to be performed on the coil by multimeter

· Check the continuity of the trip circuit by multimeter

· Check tightness of the supply terminals.