PETROL ENGINES

Classification of Petrol Engines

• Two Stroke cycle Petrol Engines

• Four Stroke cycle petrol Engines

FOUR STROKE CYCLE PETROL ENGINES

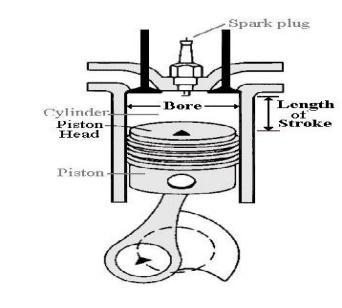

Construction :

• A piston reciprocates inside the cylinder

• The piston is connected to the crank shaftby means of a connecting rod and crank.

• The inlet and exhaust valves are Mounted on the cylinder head.

• A spark is provided on the cylinderHead.

• The fuel used is petrol

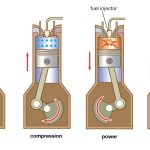

Four Stroke Petrol Engine- Working

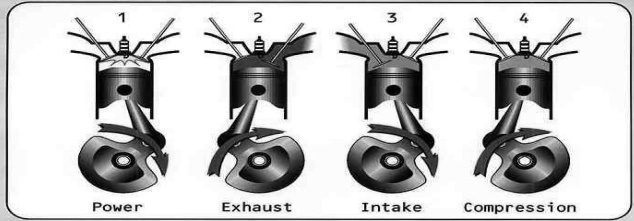

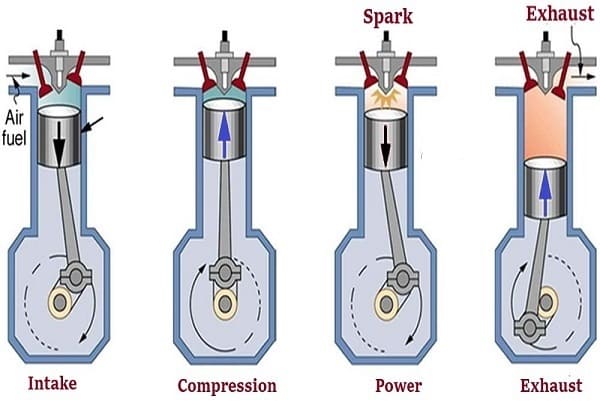

(a) Suction Stroke (First Stroke of the Engine)

• Piston moves down from TDC to BDC

• Inlet valve is opened and the exhaust valve is closed.

• Pressure inside the cylinder is reduced below the atmospheric pressure.

• The mixture of air fuel is sucked into the cylinder through the inlet valve.

(b) Compression Stroke : (Second Stroke of the piston)

• Piston moves up from BDC to TDC

• Both inlet and exhaust valves are closed.

• The air fuel mixture in the cylinder is compressed.

(c) Working or Power or Expansion Stroke: (Third Stroke of the Engine)

• The burning gases expand rapidly. They exert an impulse (thrust or force) on the piston. The piston is pushed from TDC to BDC

• This movement of the piston is converted into rotary motion of the crankshaft through connecting rod.

• Both inlet and exhaust valves are closed.

(d) Exhaust Stroke (Fourth stroke of the piston)

• Piston moves upward from BDC

• Exhaust valve is opened and the inlet valve is closed.

• The burnt gases are forced out to the atmosphere through the exhaust valve (Some of the burnt gases stay in the clearance volume of the cylinder)

• The exhaust valve closes shortly after TDC

• The inlet valve opens slightly before TDC and the cylinder is ready to receive fresh charge to start a new cycle.

Summary :

• Compression ratio varies from 5 to 8

• The pressure at the end of compression is about 6 to 12 bar.

• The temperature at the end of the compression reaches 250o C to 350o C

Comments are closed