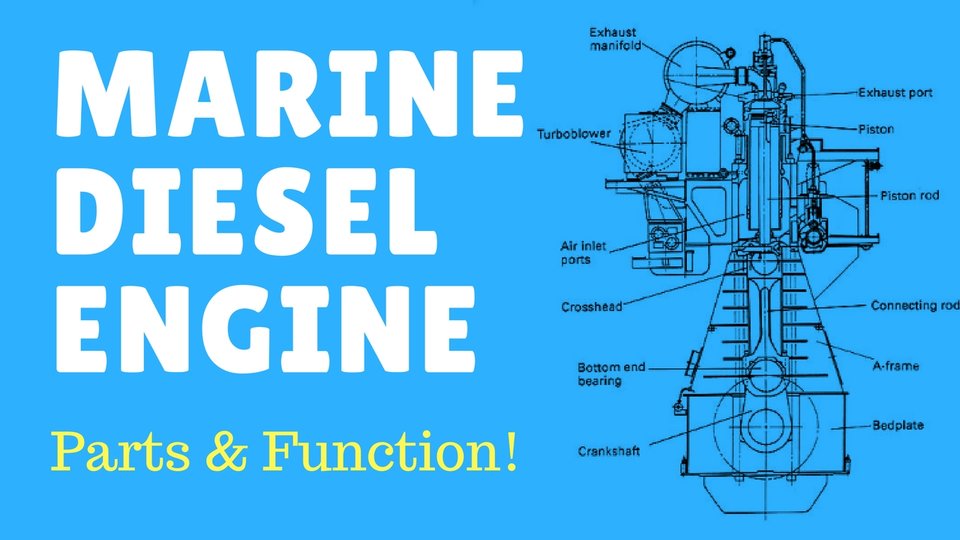

Marine diesel engines are engines used to turn the main propellers on marine ships. These engines are made up of several different components, with each component having a specific function to make the engine work as a whole.

There are 11 main components that make up the engine and they are as follows:

- Bedplate: The foundation block for the two-stroke engine, it is built to withstand the constant force from the engine, but is also flexible enough to handle constant fluctuation.

- Crankshaft: It is the main component behind transmitting power to the propeller shaft

- Camshaft: Controls and operates the main three valves (Inlet, Exhaust and Fuel Injector) within the engine— each valve produces at different speeds

- Frame Box: The frame that essentially supports the bed plate

- Piston: Used to convert the force of expanding gases into mechanical energy during the process of combustion

- Piston Rings: Seal the piston therefore, sealing the combustion chamber preventing gas from leaking into the piston and surrounding areas

- Liner: Provides a durable and heat resistant combustion chamber, preventing combustion products from escaping into the engine itself

- Connecting Rod: Takes power from the piston and transfers it to the crankshaft

- Cylinder head: Supports the valves (Inlet, Exhaust and Fuel Injector) necessary for operation

- Inlet and exhaust valves: Inject fresh air into the combustion chamber and eject byproduct out of the chamber

- Turbocharger: This component increases the overall power and efficiency of the engine

Each component plays an important role in powering and running a marine diesel engine. But the engine can’t run unless all components are in place and are in working condition.

Comments are closed