Introduction

We started to learn about one of the most important marine diesel engine components namely the piston in the previous article. In this article we will proceed to learn about the working conditions, construction and types of pistons.

Working Conditions & Construction of the Piston

Since a piston is used to seal the combustion chamber so that the combustion process takes place inside the enclosed space, you can well imagine the conditions to which the piston is subjected. On an average the upper part of the piston known as the piston crown is subjected to temperatures in the range of 450oC.

It is not possible to describe the construction of each different type of piston but an example of the construction of the oil cooled piston manufactured by B & W would give a clear idea about the general construction and all other pistons follow the same, give and take a few features.

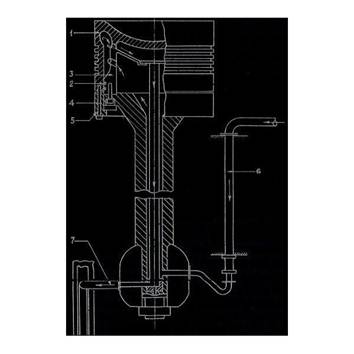

The figure below shows the sketch of one such piston and the parts are labeled as follows

1. This is the piston crown which refers to the upper part of the piston and is directly exposed to the combustion chamber and the high temperature therein. It is made out of simple casting of steel and has got grooves for piston rings.

2. Sealing Ring

3. Cast Iron Insert

4. Skirt

5. Clamp Ring

6. Cooling Oil Inlet Pipe

7. Cooling Oil Outlet Pipe

The arrows also indicate the direction of cooling oil flow and you can make out how this oil enters and leaves the piston and hence helps to keep the piston cool despite the high temperatures to which its crown is exposed. As seen earlier though the temperature above the crown could reach as high as 450oC, the cooling oil helps to maintain just around 110oC at the ring zone.

An actual photograph of a marine diesel engine picture would also help to visualize the construction on the real component, although this is not necessarily the same model as depicted in the schematic diagram but good enough to give an idea to the reader.