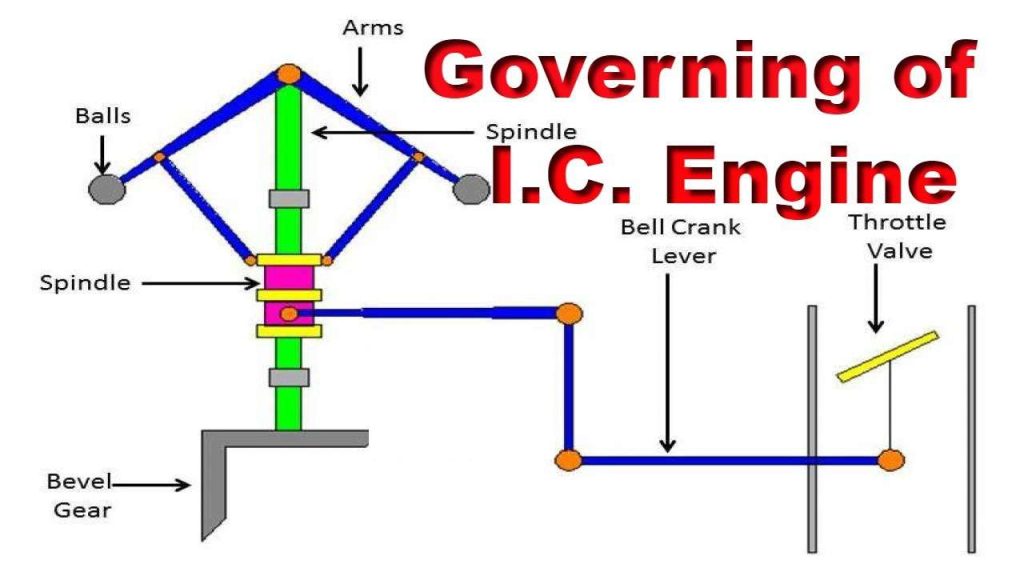

(1) In petrol engines control is accomplished by means of a throttle valve which is placed in the intake manifold immediately following the carburetor. The amount of opening of the throttle valve determines how much mixture may enter the cylinder. In automobiles the throttle valve is operated by foot control or accelerator pedal.

The mean effective pressure in the cylinder will change and consequently the power developed in the engine cylinder. The position of the throttle valve may be controlled by the speed governor of the centrifugal type. For certain applications the throttle may be positioned as a function of load while the speed is held constant.

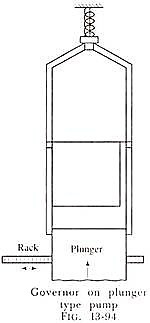

(2) In Diesel engines the fuel flow is regulated by centrifugal governor which actuates link rods which operate some device on the fuel pump for by-passing a portion of the fuel which would otherwise be injected into the engine cylinder. In plunger type injection pump, the governor changes the relative angular position of the plunger as shown in fig. 13-94. The governor operates on the rack.

Since the Diesel engine does not rely on fixed proportions of air and fuel for combustion, any fuel ratio may be used upto a point where the oxygen is all consumed.

(3) In gas engines there are three methods of governing-

(i) Hit and miss method of governing

(ii) Quality governing

(iii) Quantity governing.

(i) Hit and Miss Method of Governing:

Fig. 13-93 shows the arrangement for hit and miss type of governing.

In this arrangement when the speed rises above the permissible value, the governor sleeve rises and the lever attached to the sleeve lifts the pecker block so that the gas valve does not open; as a result only air is taken into the engine cylinder.

Thus for this cycle no power is developed in the engine cylinder due to the complete absence of the fuel and as a result the speed falls. The speed continues to decrease till the pecker block falls back into the position. Thus we see that explosions are missed intermittently, but every charge is of normal strength.

This is a simple way of governing gas engines but is not much used on other engines because this method has the disadvantage of having a comparatively large variation in speed owing extra scavenging which takes place immediately after the missed explosions. This is an efficient method from the point of view of economy in gas consumption.

(ii) Quality Governing:

In this method the strength of the mixture is changed. When the speed is high the air-fuel ratio is increased. This results in a lower pressure and hence a reduction of speed takes place.

Ignition is not always satisfactory with this type of governing. It is impossible to find the most suitable point for all mixture strengths. The thermal efficiency is also reduced.

(iii) Quantity Governing:

In this method the mixture strength remains the same, but the quantity of mixture admitted to the cylinder for compression. The compression ratio is unaltered. The air standard efficiency remains the same. There is less pressure created by the combustion of the fuel, less work is done during that cycle and consequently there is a reduction in speed.

The governor gives the admission valve a short, as a result it will open by a small amount and hence a small quantity of air-gas mixture will enter the engine cylinder. This is the light load condition. If the admission valve has a large stroke, then it will open a large amount and hence a large quantity of air gas mixture will enter the engine cylinder. This is the heavy load condition.

Since in this method there is an impulse in each cycle due to the explosion of a correct mixture, it has the advantage of giving a more even turning moment and closer limits of speed variation. This method of governing is preferred for spark ignition engines.