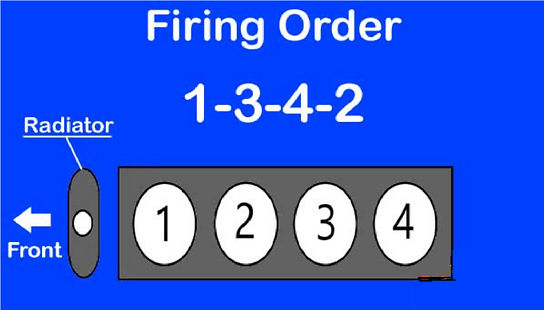

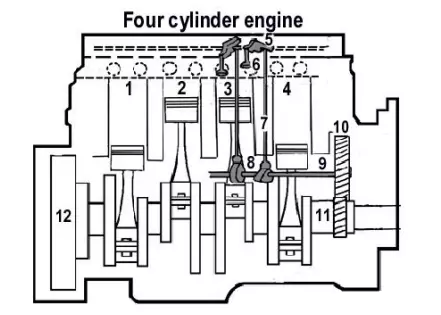

Most marine engines have several cylinders for more power and smoothness. (The cylinders are identified by numbering them in order, from the front of the crankshaft (inboard end) to the back (propeller shaft end)

Above, the cylinders are numbered 1- 4. The timing assembly consist of rockers 5, valves 6, push rod 7, cams 8, camshaft 9 and timing gear 10. The crankshaft is 11 and the flywheel 12.

In engines with several cylinders, the cylinders are designed to fire one after the other, to increase the smooth delivery of power. They do not fire in consecutive order (1,2,3,4,5,6,7,8), as this would have the effect of twisting one end of the crankshaft while the other end tries to catch up. Instead, cylinders are designed to fire, first at one end of the engine, then at the other. In this way, the power thrust is more evenly balanced on each end of the crankshaft.

Typical firing orders for internal combustion engines are:

Four cylinder engines 1,3,4,2 (sometimes 1,2,4,3)

Six cylinder engines 1,5,3,6,2,4 (or 1,3,5,6,4,2)

Vee eight cylinder engines 1,5,4,8,6,3,7,2 is most common

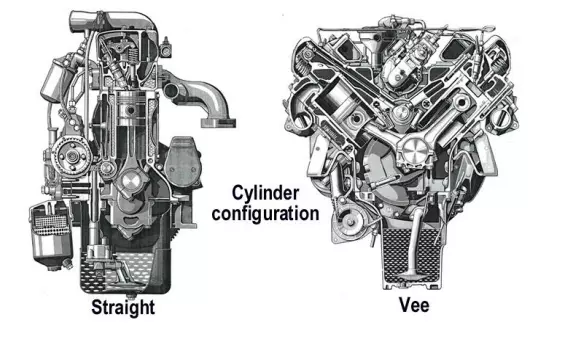

The cylinders are usually configured in a straight line along the centre of the block, being called straight. Alternately they can be configured in the vee or v arrangement as shown below fitting greater power potential in a more compact space.

Some auto engines arrange the cylinders in a horizontal plane with pairs of pistons punching out to opposite sides of the block, hence its name the boxer engine, which provides balanced performance.

Valve timing

Valve timing is the critical relationship between the position of the crankshaft and the opening and closing of the inlet valves and exhaust valves. The valve train is geared or has a chain drive with sprockets on the camshaft and crankshaft. Any slight variation from the correct timing setting will result in loss of power and overheating. Any large variation and the engine will not start.

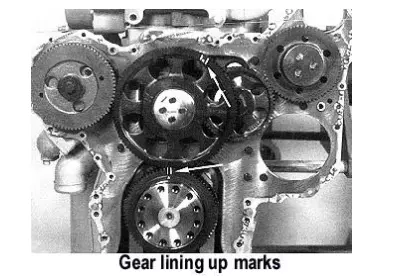

To accurately check the valve timing, it will be necessary to remove the timing cover to gain access to the timing gears. The gears or sprockets are fitted to the crankshaft and camshaft by keys so they can only be fitted in one position. However, they can be incorrectly lined up to each other.

The operators manual will indicate what the timing marks look like and in the case of chains, what the sprockets should line up with. Typical lining up marks for gears are shown below:

When timing has been found to be correct, the tappet clearances (also referred to as valve lash) should be checked. Whenever the cylinder head is overhauled, the valves are reconditioned or replaced, or the valve operating mechanism is replaced or disturbed in any way, the tappet clearance must be adjusted – also when the cylinder head has been re-tightened after the initial run in period.

As the valve and valve operating gear heats up in service, the clearance between the rocker arm and the valve stem decreases. If insufficient clearance is allowed, the valve will be prevented from seating. The correct clearance will be specified by in the operator’s manual. Some manufacturers state clearances for an engine is at its normal operating temperature, others when the engine is cold, while some give both. Clearances will vary as much as 0.128 mm (0.005”) between a cold and the normal operating temperature of an engine. Usually, an exhaust valve will have a greater clearance than an inlet valve because of their different operating temperatures.

Too much clearance will cause excessive wear, noisy operation and altered valve timing, that is, late opening and early closing. If the clearance is insufficient and the valve does not seat properly, it will result in loss of compression through valve leakage, burning and eroding of the valve and seat and general overheating.

In the extreme, it is possible that the piston could strike the valve resulting in a bent valve stem, damaged piston or worse if the valve or piston should break. If the valve operating mechanism is disturbed in any way and the engine is cold, but only a hot tappet clearance is given, the tappet clearance must be checked. If required, further adjust when the engine is at its normal operating temperature. The most common form of adjustment for tappet clearance is by means of a screw and lock nut located in one end of the rocker arm. The clearance is measured by means of a feeler gauge between the valve stem and rocker arm when the valve is in the fully closed position. This is usually done when the piston, under the valve being adjusted, is on top dead centre at the end of the compression stroke. An easy way to identify the above is as follows: On a six cylinder engine with a firing order of 1 5 3 6 2 4, turn the engine over in the direction of rotation. When the inlet valve and exhaust valves are rocking on number 6 cylinder (i.e. the piston finishing its exhaust stroke and starting its induction stroke) adjust the inlet and exhaust valve clearances on number 1 cylinder which will just be completing its compression stroke and commencing its power stroke. On the crankshaft, the bottom end journals on numbers 1 and 6 are 180° to each other, 2 and 5 are 180° to each other, and 3 and 4 are 180° to each other. What you are doing is adjusting number 1 tappets while number 6 is rocking, then adjust number 5 because it is the next one in the firing order to be on top dead centre while number 2 is rocking, adjust number 3 while number 4 is rocking, adjust number 6 while number 1 is rocking, adjust number 2 while number 5 is rocking, and adjust number 4 while number 3 is rocking.

On a Detroit Diesel, the exhaust valve/s can be adjusted on the cylinder on which the unit injector follower is fully depressed. This means that fuel injection is taking place so it is at the end of the compression stroke and the beginning of the power stroke.