|

| AUTOMATIC BACKFLUSH FILTER |

Presenting a latest Innovation in filtration method used onboard for both fuel and lube oil.Used in conjunction with a centrifugal separator as part of a complete lubricating oil system or fuel oil treatment system, the Automatic Backflush filters effectively separate impurities, according to size.Continuous backflushing helps prevent adhesion of retained solids to filter surfaces. This ensures long service intervals and drastically reduces the costs for manual cleaning, filter replacement and filter disposal.

I experienced working with these trouble free automatic backflushing filter on my last tanker vessel.

Before starting lets get familiar with some basic filtering terminology and methods.

Filtration theory

Filtration can be defined as the process of collecting solid particles from a fluid by passing the fluid through a filter medium (which could be a filter screen or a paper element) where the particles are retained.

|

| Filtration Theory |

Two basic methods of filtration are used:

1. Surface filtration, used in strainers and cake filters.

2. Deep-bed filtration, used in depth filters.

In surface filtration the particles are collected on the surface of the filter medium, whereby a filter cake of retained particles is created. This cake can be removed by back flushing the filter.

In deep-bed filtration the particles pass through a filter and are collected inside the filter.

As the solid particles accumulate in a deep bed filter or surface filter, the pressure drop increases during filtration. When the pressure drop reaches a certain level, the filter elements must be replaced or cleaned.

Many a times, onboard ship, we come across dirty Fuel or Lube with excess of sludge which causes frequent increase in pressure drop and hence requires frequent cleaning.

In this context, we then came with duplex filter where the standby filter can be manually cleaned while the other is in operation, without shutting down the system.

|

| Duplex Strainer |

What if I say that there is also a filter which continuously backflushes itself, so that there is a constant pressure drop across the filter.Which means trouble free operation with increased duration of manual filter cleaning.

AUTOMATIC BACKFLUSHING FILTER

A quick overview:

· It is always used in conjunction with a centrifugal separator.

· Can be used both for Lube oil and Fuel oil

· Continuous backflushing– no adhesion of filtrate to filter surface.

Lets have a deeper insight into this.

Many students interpret that an automatic backflushing filter can replace the centrifugal seperator. This is a completely wrong notion. The centrifugal separator cleans the oil and removes the water.The main difference between a filter and a centrifugal separator is that a filter separates the impurities according to size, while a separator works with the density difference between the impurities and the oil.

Working overview

In Automatic Backflushing Filter (ABF), the dirty oil is passed through a set of filter elements, divided into chambers. A part of clean oil coming out of the filter element is used to backflush a part of the filter element. A distributor continuously changes the chamber which is backflushed. In this way at any time, one chamber of filter element is backflushed with the clean oil.

The backflushed oil of filtering chamber is filtered in the diversion part of the ABF. Here also the filter elements are backflushed, leaving behind a minimal amount of dirty backflushed oil.

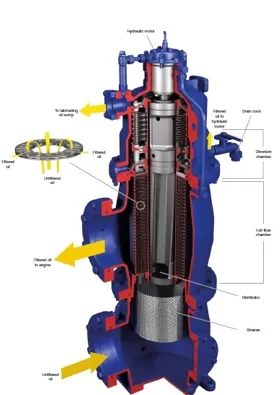

Construction details

The filter consists of the following parts

· Filter housing

· Filtering unit and Distributor

· Motor to rotate the distributor.

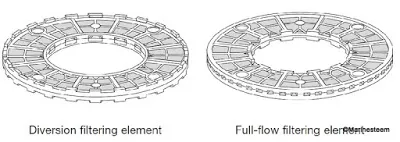

Filter housing has two chambers : Full flow chamber, and Diversion chamber.

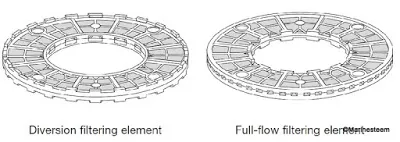

|

| Cut Section Of Automatic Backflush Filter |

Full Flow Chamber

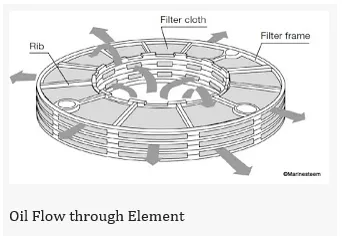

· Contains disc type filter elements,stacked on top of each other.

· Dirty oil enters in the disc stack from center and leaves from periphery.

· Each disc type filter is divided into chambers.

· At any time any one chamber is continuously backflushed with a part of clean oil from the remaining chambers.

· The rotating distributor ensures that each chamber of disc stack is consecutively backflushed with clean oil from remaining chambers

· This process ensures that none of the chamber clogs with the impurities.

· The electric motor rotates the distributor such that the distributor diverts a part of cleaned oil into the backflushed chamber.

|

| Filter Elements |

|

Diversion Chamber

· The backflushed oil of the full flow chamber is fed to the diversion chamber.

· here also there is stack of disk filters.

· the backflushed oil is filtered in the disk stack and is moved out as clean oil.

· Here also any one chamber is continuously backflushed with the clean oil of diversion chamber.

· The backflushed oil of diversion chamber is sent to

Operating principle

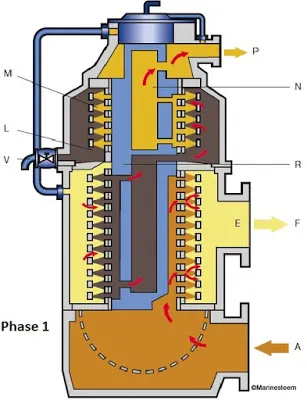

Phase 1

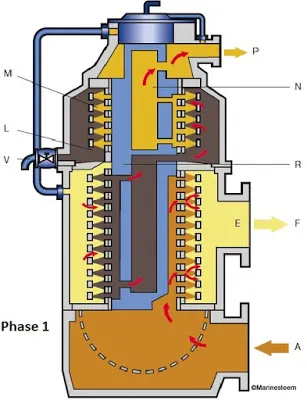

Filtering in the full-flow chamber

1. Unfiltered oil enters the full-flow chamber of the filter at “A” and flows into chamber “B” – the space between the distributor “C” and the inner perimeter of the sleeve where the filter elements “D” are fitted.

2. From chamber “B” the oil is distributed into and through the filtering columns formed by elements “D”. The solids present are trapped.

3. The filtered oil is fed into chamber “E”, where it flows to the engine through the filter outlet “F”. Approximately 200 l/h of the filtered oil flows from chamber “E” to the hydraulic motor “H” through the feed pipe “G” to drive the hydraulic motor.

|

| Phase 1 of Automatic Backflush Filter |

Backflushing in the full-flow chamber

4. While the “full-flow” filtration takes place in all columns except one, solids are removed in one column by backflushing, using part of the filtered oil from chamber “E”.

5. The backflushing oil with its solids passes through channel “K” in the distributor “C” to the diversion chamber “L”.

Filtering in the diversion chamber

6. The backflushing oil passes from diversion chamber “L” through the diversion filter elements “M” to the passage in the distributor “N”.

7. Filtered oil is taken back through passage “N” in the distributor via outlet “P”.

8. In this first phase, no backflushing is performed in the diversion chamber.

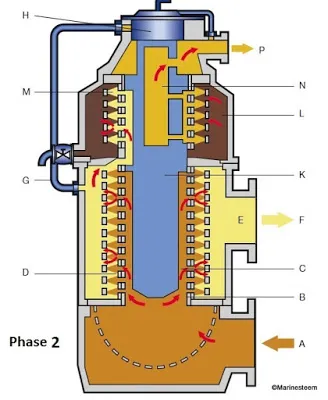

Phase 2

Filtering in the full-flow chamber and diversion chamber

Backflushing in the diversion chamber

In this phase, the distributor has rotated one step compared with Phase 1.

9. Part of the filtered oil in chamber “E” can now pass through the channel “R” in the distributor and through the diversion filter elements “M” (from inside to outside) removing the trapped particles from the outer side of the elements.

10. The particles trapped by the filtering elements “M” can thus settle to the bottom of the diversion chamber “L”. Removal of the filtered solids

11. The solids filtered out in the diversion chamber are then discharged from the system by periodic draining by an automatic or manual valve “V”.

|

| Phase 2 of Automatic Backflush Filter |

Benefits

· Long service interval

· Low maintenance cost

· High filtration efficiency

· Constant pressure drop during operation due to continuous backflushing.

· Filter screen is kept clear by continuous backflushing, which means that long service intervals can be achieved, without accumulation of particles on filter screen.

· Robust disc-type filter elements.

· Simple installation and operation

· Compact, lightweight design.

The filtration method described above gives a peek in the futuristic technology available in the market, the need is now to tap these into the use of betterment of seafaring community.

The ABF technology not only limits its employment in shipping industry, but can be used in wide array of industrial use as well.