Advantages of the duplex strainers

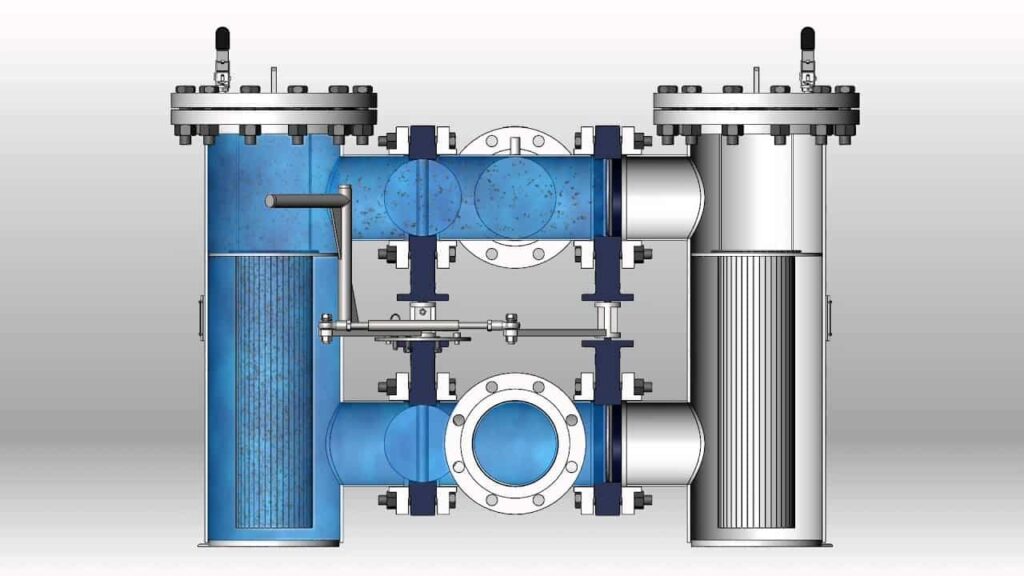

During normal operations the strengths of the duplex filter is that it can be completely operated maintenance-free, except for checking the seals and cleaning of the filter element. With two filter chambers connected with a changeover valve one chamber is always in operation while a clean filter chamber is in standby mode. Duplex filters are primarily used where shutting down machines and systems are not practical or highly uneconomical, for example, in the maritime or the production industry.

How the duplex strainer works:

Filtration phase

While one filter chamber of the duplex strainer is in filtering mode, the other chamber is always with a cleaned filter element off line. The liquid passes through the filter element and over time the pressure drop in this filter chamber will increase. The increased pressure drop is an indication that particles have been accumulated and cleaning is required. Optional a differential pressure indicator can be installed on the duplex strainer.

Cleaning phase

By activating the switch plug, the clean filter chamber will be put in operation and the dirty filter chamber is simultaneously switched off. Switching to the clean filter chamber is carried out without a pressure surge.

For cleaning, the contaminated filter chamber is depressurized by the vent screw, the housing cover is

removed and the filter element has to be removed. The filter element is cleaned by flushing it with a cleaning fluid and subsequently blown out using compressed air.