Very simply, marine insulation is an insulation product that is rated for use in marine applications. Insulation can typically be found in the walls and ceilings of a ship, but there are countless uses for custom insulation. Marine insulation can be found in boats, yachts, commercial vessels, shipping vessels or even offshore oil rigs.

Insulation is also meant to reduce the transfer of thermal heat, vibrations, and noise in and around the ship or offshore rig. Traditionally, marine insulation used cork-based products and mineral wool insulating products.

However, there have been many advancements in material science over the past several years. For example, the introduction of fiberglass-based insulation materials, polyurethane-based materials, aluminum-based insulation materials and much more.

Modern and advanced materials offer high-quality insulation properties while at the same time offering better weight performance. Modern insulation materials are also designed to meet the rules and regulations set by the International Maritime Organization. These rules dictate thermal, fire, and noise insolation.

What Makes Marine Insulation Different From Normal Insulation

Marine insulation is not the standard industrial commercial insulation you’d find in a concrete or metal building. A distinguishing characteristic of marine insulation products is its ability to withstand humidity and water. Marine insulating material should not be affected by water, especially salt water.

By default, sea ferrying vessels are exposed to a lot of water and humidity. Water and humidity can be directly responsible for the deterioration of a number of materials – insulation included. As such, unlike commercial and residential insulation, marine insulation solutions pay a lot more attention to resistance to water-induced deterioration.

Another way in which industrial and marine insulation differs is how marine insulation can play more than one role. Marine insulators should yield thermal, fire, and acoustic insulation to be effective. Marine insulators have superior thermal and acoustical performance, and can also provide noise control.

Typically, with residential and commercial insulators, their main focus is to offer effective thermal insulation with some level of fire insulation within a building envelope. However, in the marine environment, the insulating material should insulate against fire, thermal heat, and acoustic to be effective.

Marine Applications

The different types of insulation solutions available on the market are used for different applications and marine equipment. As you can appreciate, every insulation solution has its own unique properties that make it stand out from other insulators. Some of the insulation applications include:

1. Fire Insulation

For this particular application, incombustible insulators are used owing to their fire resistance performance. Drilling rigs, merchant ships, and naval vessels are susceptible to disaster in case of a fire outbreak.

Noncombustible insulators and other fire stops are used to reduce the risk of fire spreading from one end of the vessel to the other. Some of the insulation products used for this application include stone-wool and fiber-glass insulators.

Fire insulation product can either be plain insulation or insulations with facing. Plain insulation is typically used in areas where the insulation will lie beneath a fishing construction. On the other hand, insulation with facing is used in applications where the insulating material will remain visible such as suspended ceilings. As such, fiberglass cloths, aluminum foil, and other such insulators are used.

2. Thermal insulation

Thermal insulation is used to reduce the transfer of heat between the object of interest and the outside environment. In the case of marine application, it involves keeping the searing heat from radiating into the vessel or structure. In the case of commercial and naval vessels, the personnel quarters are insulated to create a more habitable environment.

Container shipping vessels use thermal insulation to maintain cold temperatures. Containers that contain products that need chilling or deep freezing are insulated to reduce heat transfer.

3. Pipe Insulation And Air Ducting Insulation

Insulating pipes and air conditioning ducts involves making the pipes and air ducts inherently insulating even before making additional steps. For instance, air ducts and pipes that carry temperature-sensitive air masses such as conditioned air are typically coated with aluminum foil. An additional layer of fiberglass cloth is applied thereafter for thermal and condensation insulation.

Alternatively, pipes that carry hot fluids are made to withstand higher temperatures. For example, the steam line or the chimney, which vents exhaust hot air from the engine. For instance, such air ducts and pipes are made using stainless steel which has a higher resistance to high temperatures. Thereafter mineral wool can be applied on the ducts and vents for even more insulation.

4. Acoustic Insulation

Marine insulation also involves acoustic insulation. Sound vibrations spreading across a vessel can create a number of issues. Not only is it uncomfortable for personnel working and living on a vessel, but it can also cause structural problems.

Moreover, there are limits to the noise and vibration transmissions as set under the ISO standard 6954. With this in mind, efforts are made to insulate the noise produced by the engine and its components, whether electrical, diesel or turbine.

The Different Types of Marine Insulation Products

There are plenty of high-performance marine insulation products for shipbuilders to choose from. Each insulation product offers a unique set of characteristics and benefits. Some of the most popular insulation products on the market include:

1. Mineral Wool Insulation

2. Microporous Structural Insulation

3. Hull boards Insulation

4. Fiberglass Insulation

5. Elastometric Pipe Cover Insulation

6. Fiber Blanket

7. Aluminum Coating Insulation

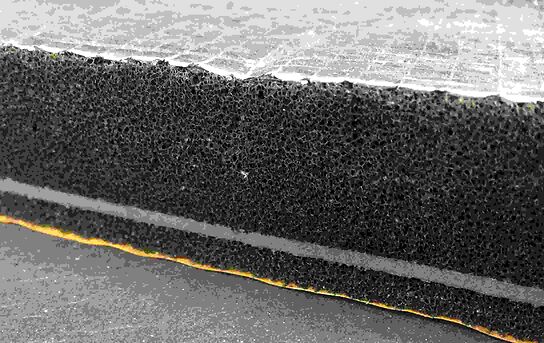

8. Foam Insulation

Foam insulation can be spray, pour, block/sheet, or flotation foam insulation.

9. Wired Mat Insulation

This type of insulation is particularly used in chimney and smoke ducts as it can withstand high temperatures.

It is important to note that a wide variety of insulations are used in insulating a vessel or an offshore rig. The use of a particular type of insulation is dependent upon the part of the vessel or rig that is being insulated. For example, a coast guard vessel may have different requirements than a cruise ship. The goal, however, is to always use the best insulation solution for a particular application.