The dual-fuel engine utilizes a “lean-burn” otto combustion process when operating on gas. Here, the gas is mixed with air before the intake valves during the air intake period. After the compression phase, the gas/air mixture is ignited by a small amount of liquid pilot fuel (LFO). After the working phase the exhaust gas valves open and the cylinder is emptied of exhaust gases. The inlet air valves open when the exhaust gas valves close, and the process starts again.

The dual-fuel engine is also equipped with a backup fuel system. In the event of a gas supply interruption, the engine transfers from gas to fuel oil operation (LFO, HFO) at any load instantaneously and automatically. Furthermore, the separate backup fuel system makes it possible to switch over from LFO to HFO without load reduction. During fuel oil operation the DF engine utilizes the conventional diesel process.

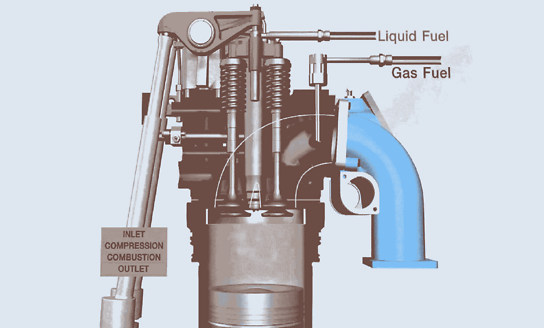

Engine working principle of gas-diesel (GD) engines

The GD engine utilizes the diesel combustion process in all operational modes. In gas mode, the gas is injected at high pressure after the pilot fuel and is ignited by the flame from the pilot fuel injection. The amount of pilot fuel is equivalent to approximately 5% of the fuel energy input at full engine load.

The gas-diesel engine can be switched over instantly to liquid fuel mode operation. The liquid fuel can be light fuel oil, heavy fuel oil or crude oil. In this case, the process is the same as the conventional diesel process.

In fuel sharing mode, the ratio between liquid and gas fuel amounts can be controlled and varied during operation. The operating window for the fuel sharing mode is 30 to 100% load and the gas/liquid fuel ratio can vary according to the fuel sharing window.

The gas-diesel process can tolerate big variations in the gas quality and is especially suitable for “non-pipeline quality gas”, such as associated gas in oil fields.