As more data-driven and detailed applications are being developed for marine electronic devices and with the convergence of multiple devices, the user interface icons are becoming more densely grouped. The more tightly packed the screen icons are, the more accuracy is required from the touchscreen to activate a specific icon among all the choices. Accuracy remains important within individual applications as well. Some navigation applications allow a chart to be developed when you accurately identify a start and stop location on the map. The ability to identify a specific location within a dense map enables the software to create the best passage from the current location to the desired location.

Integrated Touchscreen System

To help ensure the successful integration of touch-enabled devices that meet these critical application needs, device manufacturers expect the touchscreen manufacturer to supply a matched touch system that includes the touch sensor, touch electronic and often, touch drivers. Receiving a matched touch screen package helps ensure that the touch-enabled device will work optimally in the marine environment. It also provides the device manufacturer with one product source if there are issues with integration or product functionality.

Worldwide Support

Another important consideration for the device manufacturer is having reliable product support wherever the device is designed, manufactured and serviced. In most cases device manufacturers design the product in one location and manufacture it in another, either in their own facility or at a third-party contract manufacturing location. Either way the ability to interface technically in the local language at the point of design and the point of manufacture speeds the development process along and makes it easier to bring the product to market.

The 3M Solution

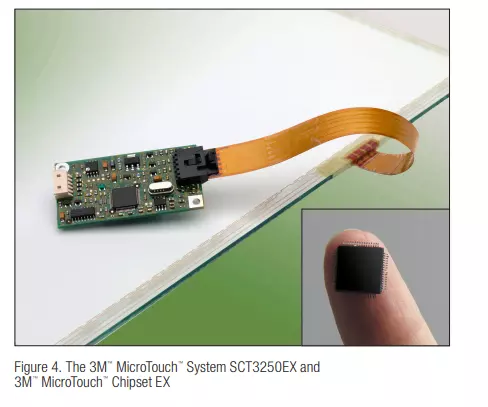

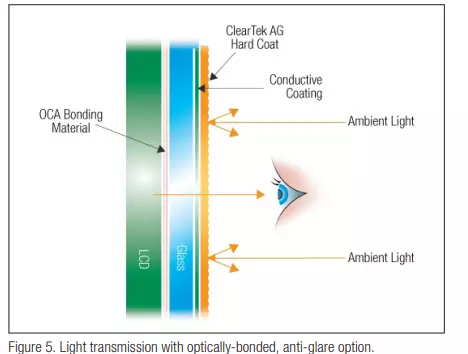

For marine electronic devices, the 3M™ MicroTouch™ System SCT3250EX (with either chipset or controller) is the best solution for the stated application needs [FIGURE 4]. The SCT3250 sensor is an all-glass, surface capacitive touch sensor with 3M-proprietary optical and anti-glare coatings. Light transmission of the SCT3250 sensor is 91.5% (±1.5%). This is slightly higher than plain borosilicate or soda lime glass which has a light transmission of approximately 90%. Borosilicate and soda lime glass are the most commonly used glass types for touch sensors. The lower transmittance of plain glass is due to light reflectance from the front and back surfaces of the glass. Light can come from the LCD, from an ambient source in the environment or can be direct sunlight. 3M’s optical coatings enhance light coming from the LCD by scattering the ambient light from the front surface. [FIGURE 5] This surface scattering prohibits direct reflection back at the viewer, thus allowing light coming from the LCD to make its way to the viewer’s eyes. The combination of

these two coatings helps increase the brightness of the display image by enabling more light from the source to be seen by the users’ eye.

Light transmittance can be increased by bonding the touchscreen directly to the LCD. As mentioned previously, the air gap between the LCD and the touch surface provides a medium through which light can be scattered, reflecting multiple times off the same surface and effectively decreasing the amount of light perceived by the eye. Closing the air gap with an optically clear adhesive enables light from the LCD to pass directly from the LCD source to the user’s eye with minimal loss of light from reflectance and light scattering. 3M has extensive experience with optically bonding touchscreens to LCD’s and is a leading manufacturer of optically-clear adhesives for various markets. Removing the air gap through optical bonding helps maintain its color

saturation, making it appear brighter and giving more depth to dark colors than unbonded displays, which in effect increases the contrast ratio of the display and makes it easier for the viewer to see the display image.

It is critical to understand the material characteristics of the bonding material. Some bonding materials have negative interactions with chemical compounds that may be present on the touchscreen. The bonding material may cause an interaction that changes the electrical characteristics of the touchscreen making it non-functional. The bonding material can also change the perceived color, so it is important to use materials that are color indexed properly.

Color can be affected by optical coatings. 3M-patented coatings are designed to remain color neutral. This is achieved through matching the indices of refraction to ensure no single coating is reacting negatively to another coating. A negative interaction between coatings can lead to a hue or color shift as defined in CIELAB.

Color can also be affected by UV light exposure, depending on the materials used in touchscreen construction. An example of a negatively impacted construction is a 5-wire resistive glass-and-polyethylene (PET) construction. With ongoing exposure to UV light, the PET can yellow, fade or crack. The amount of discoloration or change in the PET surface is in direct relation to the length of UV exposure and to the intensity of the exposure. The SCT3250 touch sensor is impervious to discoloration from UV exposure due to its all-glass construction.

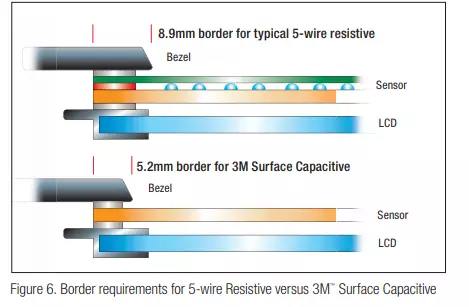

The all-glass construction not only provides a resistance to UV exposure but enables device manufacturers to seal the touchscreen within the device to a high “water ingress”standard of NEMA4 or IP66. These are two common industry standards which define the amount and velocity of water the device must be capable of withstanding. The glass thickness of SCT3250 sensor is 3.18mm (± 0.25mm) typical. The screen can be clamped to a bezel under force without damage and will continue to function under the pressure. Some technologies, like 5-wire resistive, struggle to achieve a water tight seal. 5-wire resistive sensors are made by separating two conductively-coated substrates with spacer dots. The force needed to create a water tight seal may inadvertently depress the spacer dots and put the two conductive surfaces in contact with each other thus creating a false touch input. Resistive touchscreen manufacturers suggest clamping the touchscreen outside the viewable area. This may make the integration of the marine electronic device more difficult and may require a wider border or bezel area. Figure 6 is a representation showing the difficulty in sealing resistive in a water tight device due to border area and sensor construction.

The marine environment is one of extremes, so product robustness is very important. One major focus of this robustness is the durability of the touchscreen’s front surface. Marine device manufacturers need to maintain the optical clarity of the display under environmental conditions like high UV exposure, as well as requiring scratch resistance for functional durability and optical clarity. The SCT3250 sensor is an all-glass solution that is unaffected by extended UV exposure, so it does not degrade or change color and thus maintaining its optical characteristics are maintained.

3M’s surface capacitive technology uses the proprietary 3M™ ClearTek™ Hard Coat and a separate scratch-resistant top coat. A common way to compare the scratch resistance of glass and other materials is to use the MoHs hardness scale. MoHs hardness refers to the ability of a material to resist scratches or abrasions. It was devised by Friederich Mohs in 1812 and ranks gemstones according to hardness. The softest gemstone has a rating of 1 and the hardest has a rating of 10. A diamond is representative of a 10 on the MoHs scale. The 3M ClearTek hard coat and scratch-resistant top coat provide functional scratch-resistance against common materials that have a MoHs rating of less than 7. Materials that fall into this category can create an aesthetic scratch, but not a functional scratch.

Another aspect of robustness is the ability to operate in climates with very different temperature ranges. A marine electronics device can be found in the cockpit of a boat in the cold climate of the Arctic and in the warmer and more humid climate of the equator. The touchscreen system which includes electronics must be able to operate under these varying conditions. The SCT3250EX system is an all-glass solution that can operate in temperatures as high as 70 degrees C and as low as -40 degrees C. By comparison, a standard 5-wire glass-and-PET construction cannot generally operate in temperature ranges greater than 35 degrees C or less than -10 degrees C. Another concern for 5-wire resistive glass-and-PET touchscreens in use at higher temperatures is the different coefficients of expansion of the glass, PET and bezel materials of the marine device, which may lead to buckling of the PET top sheet when it is clamped tightly to the bezel. Because SCT3250 sensor is a single layer material construction it has a single coefficient of expansion and will not exhibit any of the issues of a 5-wire resistive glass-and-PET construction.

As user interfaces become increasingly complex with more data available on the same display, the ability to accurately pick a specific icon becomes more difficult and more important. The reported touch coordinates of the SCT3250EX touchscreen system are within 1% of true position, based on the diagonal dimension of the touchscreen. This enables more icons to be displayed on the touchscreen without negatively impacting the ability of the user to accurately select the targeted icon.

Marine device manufacturers are interested in getting a complete touchscreen system from one manufacturer. This ensures that the electronics and the touchscreen work optimally together with reduced compatibility and integration issues. 3M Touch Systems sells component systems. Our electronics products can be purchased either as a separate controller that can be integrated into an overall design or can be provided as a chip set solution. The advantage of the chip set solution is it allows the device manufacturer to add the touchscreen circuitry and chip on to an existing board design. This effectively decreases the amount of space and can help shrink the overall design package of the electronic device.

3M touch products are supported by mechanical, electrical and firmware engineers who are able to maximize performance of the overall system. 3M understands the value of purchasing a touchscreen solution from one source that provides optimized functionality and maximum reliability.

Marine device manufacturers are worldwide operations that are looking for the same support from their supply chain. Most manufacturers have multiple regional design centers with manufacturing occurring either in a third separate location or at a third-party integrator. The ability to support design centers and manufacturing locations with local, in-country personnel is important. The language barriers that can exist with companies that do not provide worldwide support are not an issue with 3M. The ability to communicate and technically support design centers and manufacturing plants shortens product development time. This enables the device manufacturer to develop a product and bring it to market faster, enabling them to respond to market and consumer needs more rapidly.