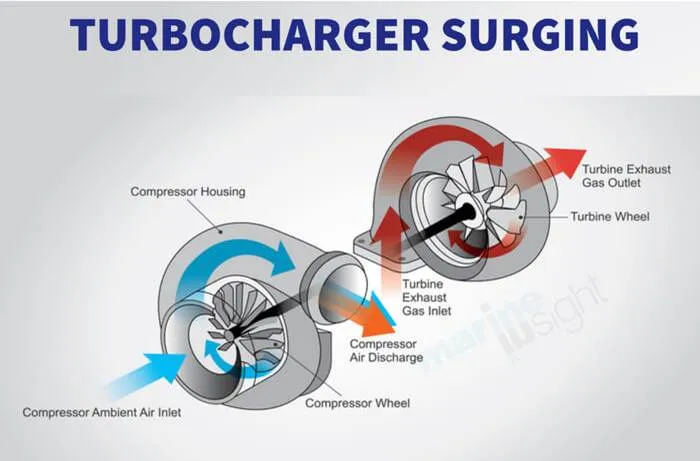

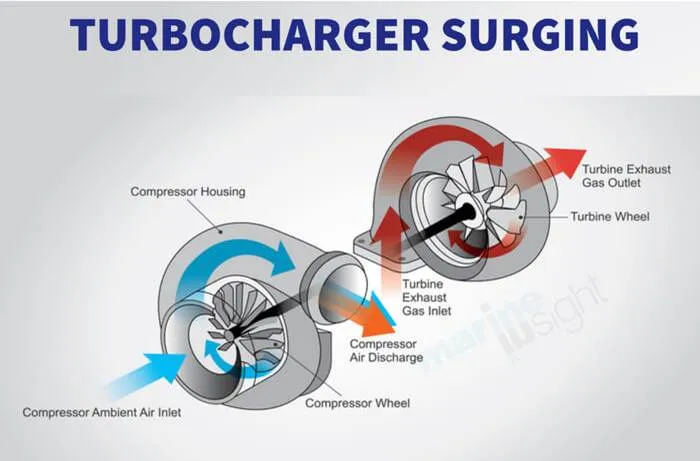

Turbocharger surging may be defined as a high pitch vibration of audible level coming from the blower end or compressor end of the turbocharger. It is frequently experienced in low-speed diesel engines, and a sea-going marine engineer must have heard this howling sound generated from the engine at least once in his/her sea career.

Whenever the breakdown of gas flow takes place in the turbocharger, a reversal of scavenging air occurs through diffuser and impeller blades into the blower side which causes surging. In simple words, a big mass of oscillating airflow can cause vibration of the turbo compressor impeller and its vanes, which make the compressor unable to operate normally, producing a high pitch noise as a reaction, which is known as compressor surge.

Credits: abb.com

Other terminologies such as turbo surge or engine surge may also be used to describe this phenomenon, but the directly involved component in surging is the compressor of the turbocharger or the turbo-compressor. The turbine side or exhaust gas side of the turbocharger does not play a direct role in the surging process. It may undoubtedly affect the performance of the complete turbocharger, which may lead to the turbocharger surging.

During engine operation at sea, few events of surging may occur as it also depends on external factors such as sea state, weather, abrupt manoeuvring, crash stop, etc. Such cases of compressor surge are acceptable. However, the engineer on the ship must ensure that the condition of the turbocharger bearing and the lube oil are in good service condition.

If the surging happens during normal engine operation and the frequency of engine surge is high, it may lead to damage to the bearing and in some cases, results in mechanical failure of the compressor rotor. Hence, the turbocharger surging is a result of various engine parts not performing in sync. A worn out engine cylinder or fuel system may lead to problems in the engine and the turbocharger. This will result in less air flow to the compressor against the higher back pressure, making the compressor surge.

Therefore, turbochargers must be matched properly with the engine air consumption rate and pressure across the operating range of the engine and should not fall into the surge limits.

The Surge Line

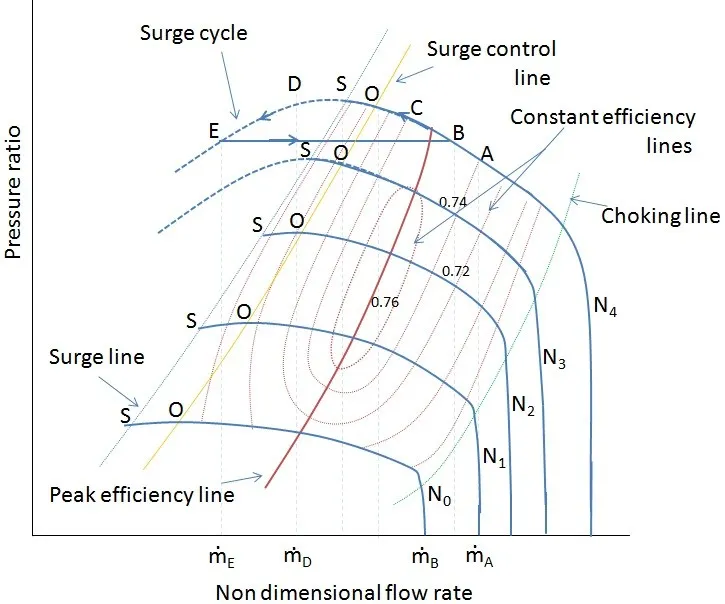

As shown in the graph, the operating line of the engine should maintain the pressure and volume of the intake air at point A to maintain the equilibrium and efficient working of the turbocharger. Suppose, there is an increase in the intake air volume, the pressure will decrease on the line of constant speed. To maintain the equilibrium, i.e. to be on the operating line, the volume has to decline.

However, if there is a slight decrease in volume at point B (at the same pressure as A), it will result in the reduction of pressure on constant speed line. At this stage, the compressor will not be able to maintain the required pressure and the volume will further decrease leading to compressor surge.

Terms Associated with Turbocharger Surge

Surge pressure dip: The surge cycle has a specific pressure dip and if the cycle continues without changing the operating point, the size of the pressure dip will sustain.

Surge cycle time: The time at which the surge starts until the operating point is changed to reach the equilibrium again, i.e. the end of engine surge.

Surge temperature behaviour: As the surge happens, there will be a reversal of air flow, leading to change in the temperature of the upstream.

Surge shaft speed variations: The shaft of the turbocharger containing compressor and turbine wheel will also experience a change in speed during the compressor surge

The turbochargers should therefore appropriately match with the engine air consumption rate and pressure across the operating range of the engine, and should not fall into the surge limits.

Image Credits- Wikimedia/ Sunil Chaudhari

Category of Turbocharger Surging:

Mild surge: The surges happening under mild conditions are not significant. They may rise due to no flow reversal and small oscillations in pressure.

Classic surge: Classic surge which happens due to low-frequency oscillations with larger pressure oscillations.

Deep surge: This is the critical condition when the reversal of the mass flow occurs in the compressor which leads to surging.

What are the Causes of Turbocharger Surging?

The following are the causes of turbocharger surging:

Improper power distribution: Inadequate power distribution between the main engine cylinders may cause turbocharger surging as one unit is producing more power and the other is producing less. Due to this the air consumption required by both the turbochargers differs, which leads to surging.

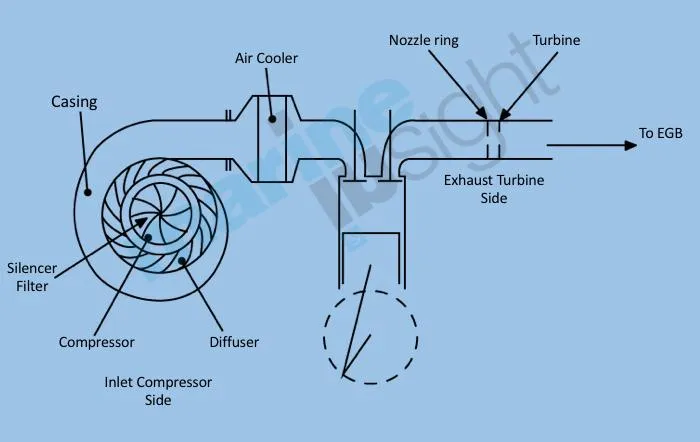

Engine-Turbocharger Arrangement and Associated Parts

Fouled turbocharger parts:

· If the inlet filter for the compressor on turbine side is dirty, then enough air cannot be supplied for combustion, which leads to surging.

· Similarly, if the turbine side is also dirty i. e nozzle, blades etc. enough air cannot be produced for combustion

· Damaged silencer

· Worn out turbocharger bearings

Problems in the Scavenge Air System:

· Fouled air cooler and water mist catcher

· No water circulation inside the cooler

· Fouled cooling tubes

· Carbon deposits in scavenge ports

· High receiver temperature

Problems in the Exhaust System:

Highly fouled exhaust i.e. economizer, if fitted, may cause back pressure in the turbocharger and thus finally lead to surging. Other exhaust problem may be as follows:

· Exhaust valve malfunctioning and not opening properly

· Damaged or blocked protective grating before the turbocharger

· Pressure pulsations after turbocharger and inside the exhaust receiver

· Damaged compensator fitted on the line of turbocharger entry

Problem In the Fuel System:

If the fuel system is not operating efficiently, it can be due to the following problems:

· Low circulating or supply pump pressure

· Air or water in the fuel oil

· Low preheating temperature of the fuel

· Defective fuel pump suction valve

· Sticking fuel pump plunger and valve spindle due to carbon deposits

· Damaged fuel valve nozzle

· Faulty load distribution system

Other Factors:

· Due to bad weather, the engine suddenly starts racing, and sudden load change takes place. This happens because, during bad weather or pitching, the propeller moves in and out of the water, causing the change in load on the engine

· Badly matched engine and turbocharger tuning, which may occur in the old engine due to the isolation of one or more unit or a faulty engine part

· Change in the ambient condition, i.e. pressure and temperature variation

How to Prevent Turbocharger Surging?

The following are the ways to prevent turbocharger surging. However, it is to note that some points may vary with design and construction of the turbocharger.

· Keep the turbocharger intake filter clean.

· Water-wash the turbine and the compressor side of the turbocharger

· Proper maintenance and checks should be done for different turbocharger parts periodically. If there are any issues, turbocharger repair to be done as soon as possible without loading the engine

· Soot blow should be done from time to time in case of economizer or exhaust boiler

- Indicator cards to be taken to assess cylinder and power distribution of individual units

- Ensure the engine auxiliaries and parts which affect the turbocharger are maintained properly

- Efficient maintenance of air cooling system

- Regular cleaning and inspection of economizer

- Regular cleaning and inspection of the exhaust manifold

Comments are closed