A hydrophore system is used on a ship to maintain constant water pressure to all parts of a ship ( varying over different lengths and heights ) at all times without continuous pump operation.

Based on their working medium it can be further classified into a freshwater hydrophore system and salinity water hydrophore system.

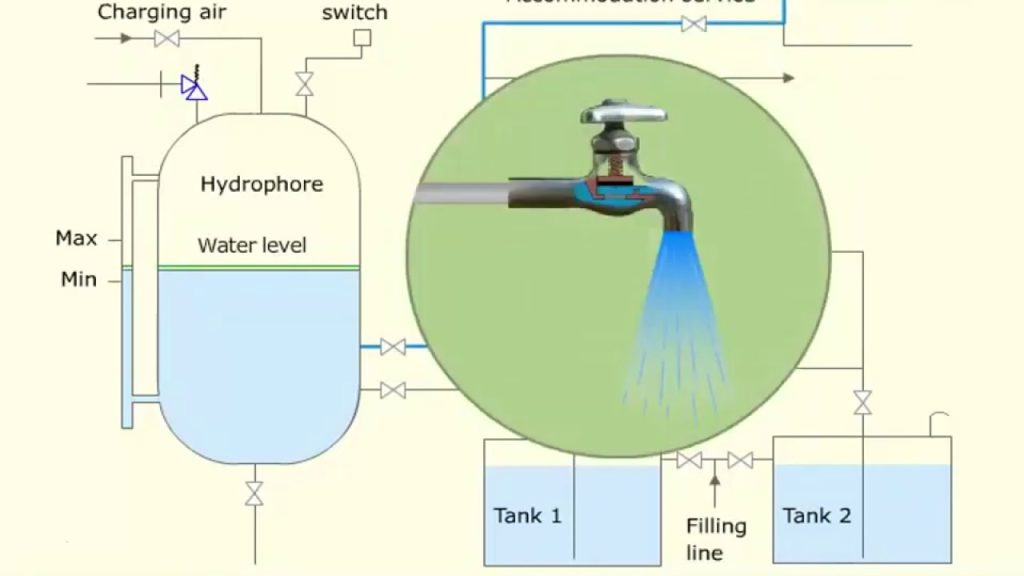

The system consists of at least two hydrophore tanks, freshwater pumps, different gauges to monitor, freshwater tanks, few safety devices, a few automation for pump cut in and cut off, and compressed/pressurized air.

Why Use Hydrophore System In first Place

Have you ever imagined how freshwater is transported to all decks and places on the ship? Do they use Pumps 24 hrs? No ! Hydrophore system is used onboard to provide water to all compartments and decks on a ship. There is the continuous use of water on the ship from drinking to sanitary purposes.

So to reduce unnecessary power consumption and maintenance costs for pumps; hydrophore systems are installed on a ship.

Most of you must be familiar with the water tanks on the top of our home or on street at quite some hight (Huh?) where pumps are used to store water.

Gravity works as a source to supply water at desired pressure at all points. Ships too have tanks to store water (fresh and domestic water tanks), but instead of having them at the top; They are situated at the bottom of the ship out of the reach of gravity to be used as a method to transport water.

So we have domestic and drinking freshwater system onboard ship which utilize the pressure in hydrophore tanks to supply fresh water. Freshwater from the domestic fresh water tank is pumped to the hydrophore tank through any of the two pumps.

These pumps are controlled by the pressure switches installed on hydrophore tanks. When the pressure inside the hydrophore reduced to a certain value the pump start. On board ship, there is a separate hydrophore tank and supply line for drinking water known as drinking fresh water line.

© IMO – 2018 | CC BY 2.0

How Does Hydrophore System Works?

Hydrophore system works on one of the simplest principles known as “Water is incompressible”. Water is stored in the hydrophore tanks situated in the engine room; It is then pressurized using compressed air from the air bottle via a pressure reducing valve.

An equilibrium is maintained in between the levels of air and water with air pressure; which helps in transporting water to the top. In the drinking freshwater system, the output from the hydrophore tank goes through a U.V sterilizer before consumption.

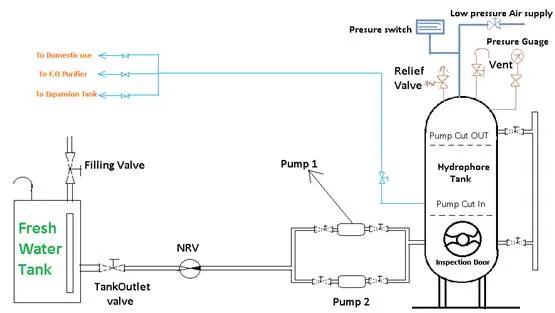

In the hydrophore system, a hydrophore pump (Centrifugal) takes suction from the freshwater tank through the tank outlet valve, non-return, and pump suction valve.

These pumps can be either self primed or are situated at a lower level that of the tank. Once pumped it is discharged into a hydrophore tank via the pump discharge valve. These pumps are operated based on the hydrophore pressure using a pressure switch. This pressure switch on the hydrophore tank contains a below that expands and contracts based on hydrophore tank pressure.

It is this device which send signal to selector switch that pass on that signal to continue pumping to the selected pump. You can consider it’s working similar to that of below in your bathroom sink.

Once water is pumped in the hydrophore tank to a certain limit; Low pressure compressed air is then introduced from the top at a pressure of 4.5 bar. An equilibrium is maintained at 70% water and 30% air with the pressure of tank be 5.3 to 5.5 bar.

The output from the domestic freshwater hydrophore tank is connected to lines for domestic use, to fuel oil purifier and expansion tank; while the output of drinking freshwater tank to the U.V sterilizer and then to accommodation.

Equipments & Mountings Of Hydrophore System

1. Fresh water pump ( 1 and 2)

2. Vent

3. Suction and discharge valve

4. Non return valve

5. Hydrophore tank

6. Low pressure air line (4.5 bar)

7. Pressure switch

8. Fresh water tank

9. Pressure gauge

10. Inspection gauge

11. Gauge glass

12. Relief valve

Charging Procedure

Charging the hydrophore system is a simple process of adding more compressed air to pressurize the hydrophore tank. Generally the hydrophore tank is under auto mode; which controls the cut-in and cut-out pressure of hydrophore pumps. But to charge the system manually; first open the vent, start the pump and watch the level through sight glass.

Wait for some time, until the water reaches about 70% of the total capacity. Close the vent and open the low-pressure air supply valve. Quickly Charge the hydrophore tank up to it reach 4.5 bar pressure of air.

Once it’s at 4.5 bar reduce the rate of charging pressure air and slowly take it to 5 to 5.5 bar based on manufacturer recommendation. Avoid overcharging, otherwise air will came out of the taps with water. If undercharged the water won’t reach to the top of accommodation.

Now transfer the system on auto. Now the pump will cut-in when the pressure reaches 4.5 bar and cut-out when it reach 5 to 5.5 bar.

In small ships or industries with small hydrophore the system may be required to cut in at 2.5 bar and cut out at 4.5 bar. Make sure the water is always visible through the gauge glass throughout the operation.

Watch-keeping Facts/Tips

If hydrophore pumps are running more than usual, then there is a high possibility of:

· Pipe leakage

· Undercharging

· Open taps at many points

· Wrong pressure switch setting.

Common Problems And Their Solutions

1 ) Under Charge

Being under charge is one of the most common problem of hydrophore. In this condition, the water level is more than 3/4 parts of the volume. This means air is leaking from either; relief valve, isolation valve, air supply valve, vent valve or the gauge glass itself. The situation can be found with no water supply at the accommodation top.

Solution

Temporarily you can fix this problem by switching pump to manual and drain the excess water or utilizing in engine room. Once the water level reach the 3/4th of the tank volume crack open the air supply line to charge it with compress air.

Once the pressure reach 4.5 / 5.5 depending upon your hydrophore cut off pressure; stop the compressor and put the pump back to auto. But for long term solution, you have to apply soap solution on all joints and key leak point. Once leak detected stop and DE-pressurize the system and rectify the fault.

2 ) Over Charged

This is quite rare but possible problem you may face with hydrophore system. In this condition there is more than 1/3rd of the air volume at the pump cut out pressure.

This means there is a leak in air supply line or the valve itself slowly filling tank with more and more air. The situation can result into no water in hydrophore tank in some cases and thus be reacted quickly with care.

Solution

At first fix this problem temporarily by crack open the vent valve and letting some air go. Then when the air pressure is 4.5 bar or 2.5 bar based on its cut in pressure close the vent valve and switch your pump on auto.

Make sure that the pump cutoff at 5.5 bar otherwise the system need immediate maintenance. In long run prepare the system to be DE-pressurize; open air supply valve and overall it.

Once done start the pump on manual and fill the water till its 3/4th of the volume. Open your air supply valve and pressurize tank up till 5.5 bar and set the pump on auto. Make sure to watch that the pump cut-in and cutoff at the desired pressure next time.