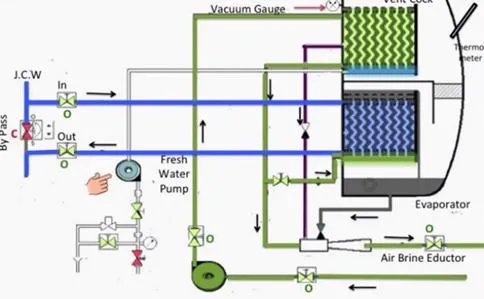

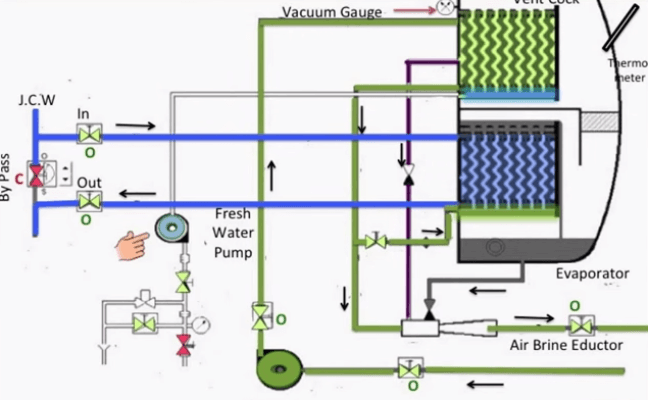

Fresh water generator, one of the important machinery on board a ship, is something that cannot be done without. Fresh water produced from fresh water generator is used for drinking, cooking, washing and even running other important machinery which use fresh water as a cooling medium.

Fresh water is generally produced on board using the evaporation method. There are two things that are available in plenty on ship to produce fresh water –Seawater and heat. Thus fresh water is produced by evaporating sea water using heat from any of the heat source. The evaporated sea water is then again cooled by the sea water and the cycle repeats.

Generally the heat source available is taken from the main engine jacket water, which is used for cooling the main engine components such as cylinder head, liner etc. The temperature available from this jacket water is about 70 deg. centigrade. But at this temperature the evaporation of water is not possible as we all know that the evaporation of water takes place at 100 deg centigrade under atmospheric pressure.

Credits: marineinsight/YouTube

Thus in order to produce fresh water at 70 degrees we need to reduce the atmospheric pressure, which is done by creating a vacuum inside the chamber where the evaporation is taking place. Also, as a result of the vacuum the cooling of the evaporated sea water will also take place at lower temperature. This cooled water is collected and transferred to the tank.

Faults in fresh water generator

Faults in freshwater generator reduce performance of the system, thereby reducing quality and quantity of freshwater produced on ships. These irregularities must be identified and rectified immediately to ensure that the optimum performance of the freshwater generator is achieved.

Typical faults in fresh water generator are:

Loss of Vacuum or Over-pressure of Shell

The shell pressure of the freshwater generator rises and rate of freshwater produced reduces. The reasons are:

1. Air leaks into the evaporator shell in large quantities and air ejector cannot cope.

2. The cooling water flow through the condenser is reduced or cooling water temperature is high. This cause saturation temperature and hence saturation pressure within the condenser to rise.

3. Malfunctioning of the air ejector.

4. The flow rate of the heating medium increased and excess water vapor produced. Since this excess vapor cannot be condensed, shell pressure increases or vacuum falls.

Salt Water Carry Over

Salt water may be carried over in large quantities during operation of the fresh water generator. This is called priming. General reasons of the priming are:

1. Level of salt water inside the shell is high. When the water level is high agitation due to boiling occurs and saltwater may carry over along with the vapours.

2. When the salt water brine density is too high, agitation of salt water occurs which results in priming.

3. Increased evaporation rate.

Gradual Increase in Level of Brine

For the satisfactory operation of the fresh water generator, a constant level of brine to be maintained in the shell. Brine is the concentrated seawater after the liberation of water vapours. This brine is gradually extracted from the shell. Usually, this is achieved by the combined air-brine ejector. It extracts air as well as brine from the shell. Any fault in the ejector or brine extraction pump (in some models) cause the increase in the brine level.

Increase in Salinity of Freshwater

Possible causes are:

· Brine level inside shell too high.

· Leaking condenser tubes or plates.

· Operation of evaporator near shore with contaminated feed water.

· Shell temperature and pressure too low.

· Increased solubility of CO2 generated from the salt water due to reduced seawater temperature. This dissolved CO2 makes water acidic and conductivity of water increases. Hence salinometer shows increased salinity, which is a measure of conductivity and not the presence of salt.

Comments are closed