Formation of marine boiler : A boiler in one form or another will be found on every type of ship. Where the main machinery is steam powered, one or more large watertube boilers will be fitted to produce steam at very high temperatures and pressures. On a diesel main machinery vessel, a smaller (usually firetube type) boiler will be fitted to provide steam for the various ship services. Even within the two basic design types, watertube and firetube, a variety of designs and variations exist.

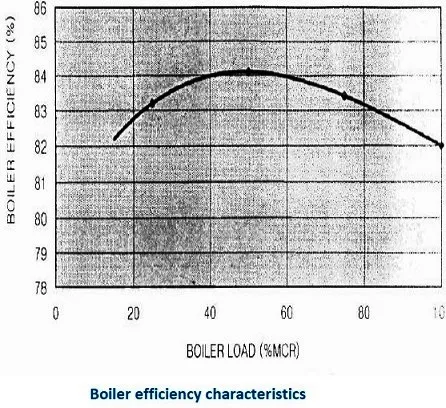

Fig (i): Boiler efficiency characteristics

Boiler energy efficiency measures

Figure (i) shows typical energy efficiency characteristics of a boiler that is normally specified by boiler manufacturer. As can be seen, the boiler efficiency is a factor of its load.

In operation, the efficiency tends to be lower than the above design values. There are a number of major areas that need to be managed in order to keep the auxiliary boiler at its highest energy efficiency levels as signified by Figure (i).

Fouling of surface

The boiler main function is to generate steam at correct pressure and temperature and with best energy efficiency. Optimal energy efficiency means optimal transfer of fuel energy to boiling water via various boiler pipes and heating surfaces. Aspects that could lead to a reduced rate of this heat transfer include:

· Fouling of boiler tubes and heat transfer surfaces on the gas side

· Fouling or scaling of boiler tubes on the water side.

The above will normally translate into a less heat transfer from gas and more heat retention by the exhaust gases as they leave the boiler. Thus high boiler outlet exhaust gas temperature could be a good indication of such fouled conditions. To remedy the case, maintenance practices should include boiler’s soot blowing, de-scaling, good water, combustion adjustments (to reduce soot formation) and son on. For this purpose, the heat transfer areas of the boiler must be monitored.

The soot blowing of the boiler must be done regularly as build-up of soot acts like an insulator and reduces the heat transfer rate. The same goes for the buildup of scale in the water tubes. The stack temperature must be monitored regularly and any increase in it means that heat recovery is not optimum. High increases of exhaust gas temperature beyond those experienced after the last cleaning would indicating build-up of fouling and would require another cleaning action.