Resurfacing of bronze rudders and propellers is required after the boat has been subjected to the ravages of seawater immersion. This causes several types of corrosion that along with flow induced damage leave the components badly pitted, necessitating a spell on the slips to remove them for repair.

Most boat rudders and propellers are cast from good quality alloys in an attempt to reduce corrosion and other wear from immersion and operation in seawater. Depending on the design and requirements of the boat, a boat’s rudder can be fitted outboard, being hung aft, or inboard hung under the hull. Inboard rudders are more efficient and not so susceptible to wear as the outboard ones, although outboard rudders can save space and are more easily fitted and maintained.

Boat propellers are designed to suit the hull and engine configuration, having three, four, or five blades.

The following sections examine the repair of worn rudders and propellers; the first section deals with the different forms of attack on them in the underwater sea environment.

Causes of Rudder and Propeller Wear

The rudder and propeller are under constant assault from the following threats.

· Corrosion from seawater

Propellers and rudders cast correctly from good quality alloys have a good resistance to seawater corrosion. Over time, immersion in seawater forms a film on the boat’s propellers and rudders, acting as a protection against extended use in seawater.

However, cheaper inferior alloys that have been badly cast will not develop this overall protective film, but a patchy one. This allows the seawater to corrode the components, exhibiting the classic green color oxides in bronze components and red/brown oxides for stainless components.

· Erosion

This is a mechanical form of corrosion caused by the rotation of the propeller producing air bubbles. These bubbles flow aft, constantly bombarding and bursting against the rudder surfaces, creating pitting.

· Cavitation

Cavitation can attack the propeller on its scrolls or at the blade tips. It is caused by excessive loading or constant high revs. The blade tips become eroded due the action of the seawater flowing around the tip of the blade from the pressure side to the suction side. An example of cavitation damage to a propeller is shown below; please click on the image to enlarge.

· Galvanic Corrosion

This is caused by dissimilar metals in contact being immersed in seawater, an excellent electrolyte! This acts as a battery, with the current flowing from the less noble metal to the more noble one. An example of this is a bronze propeller fitted to a stainless steel shaft. Galvanic corrosion increases with a rise in temperature of the seawater, and galvanic coupling can also occur in a rudder or propeller that has been cast from an inferior alloy.

· lectrolytic Corrosion

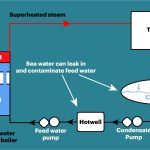

Finally, it is worth mentioning electrolytic corrosion. This occurs gradually due to bad earthing (grounding) of the components, but it becomes a really serious problem when the boat is tied up at a marina and connected to shore electricity supply. The battery effect we saw in the galvanic corrosion is similar to this situation, except that this time stray currents provide the power. All boats fittings, including bronze rudders and props, create an electric circuit with the marina steel piles initiating the corrosion.

Repair of Bronze Rudders and Propellers by Resurfacing

The repair of bronze rudders and propellers normally requires the boat to be pulled up onto a slipway, lifted out of the water to the quayside or dry-docked.

The resurfacing and machining of the rudder can be carried out by an experienced DIY person. However because of balance requirements and blade profile, propeller resurfacing and subsequent machining is best carried out by a professional repair engineering company.

There are several methods used to resurface the components to their original thickness and profiles; two current ones are;

· Bronze Alloy Epoxy Resins

· Laser Coating

Epoxy Resins

The components are transported to the boatyard’s workshop where they are shot-blasted using nonmetallic grit to create a key for the epoxy filler. They are then dipped into a bath containing a cleaning fluid such as a tetrachloroethylene-based degreasing agent before being dried. Old cloths or rags are not used for this operation as threads can be left on the rough surfaces that can act as wicks, so therefore air drying is normally used.

The components are now ready for the application of the epoxy. This is carried out manually using suitable flat and round wooden bladed hand-tools.

Epoxy is normally supplied in two parts of different colors to assist with the mixing; a thick paste is used for corrosion/erosion damage on the rudder; a more liquid epoxy mix being applied to the pitting on the propeller.

Once cured, a further coat of epoxy can be applied then the components left aside and allowed to fully cure until the epoxy is hard.

The components can now be machined; the rudder by a milling machine, before final sanding to a smooth finish by hand.

The propeller is machined using a machine tool such as a CNC or other specialist milling machine to the original blade configuration. The components can now be re-fitted to the boat.

Author’s Notes on Protection against Corrosion

Prevention is better than a cure so I have included a few notes on protection against corrosion;

1. Zinc anodes can be used to help protect the components from galvanic corrosion. Aero-dynamic shaped anodes can be bolted to the rudder to prevent galvanic corrosion between stainless pins and rudder/rudder bushes. A split zinc anode collar supplied in two halves can be fitted around the prop shaft just f’ord of the propeller. This will prevent galvanic corrosion between the stainless steel prop shaft and the bronze propeller. A sketch of the arrangement is shown below.

2. A galvanic isolator can be fitted to the boat’s electrical earthing circuit to prevent stray currents causing electrolytic corrosion damage.

3. Although laser coating using powder is a relatively new method of resurfacing, in the past I have built-up worn steel components such as screw conveyors and wear plates using stick welding. This provided quite a hard surface that proved difficult to machine using normal equipment; a 6″ hand grinder did the job in the end.

4. I have included a link to laser coating technique in the reference section for information and a link to US companies specializing in resurfacing rudders and propellers.

Comments are closed