This article discusses the different types of compressors used on board, the uses of compressed air on board, unloading of compressors, safety features of compressors, operating procedure of compressor, routine maintenance of reciprocating compressor, valves overhaul procedure, trouble shooting, etc

Different Types Of Compressors Used On Board

Compressors are used for compression of gases by decreasing the volume and imparting a corresponding increase in pressure. There are a different types of compressors used for different uses onboard. We have refrigeration compressors used in air conditioning and refrigeration. We have air compressors for supplying compressed air; we have compressors on the engine turbochargers supplying compressed air to the engines for combustion. There are different types of compressors like centrifugal compressors, rotary vanes compressors, rotary screw compressor, reciprocating air compressors, etc. In this article we shall be discussing the reciprocating air compressors.

Onboard we have different types of air compressors in use. There are main air compressors used for supplying high pressure air for starting of the main engine and auxiliary engines, control air compressor for supplying control air, topping air compressors for topping up and taking account of the leakages, and on some ships we have deck air compressors to give air for the use on decks. In addition we have a special oil free compressor for filling up the breathing air bottles known as the breathing air compressors.

Generally two pressures of air are used: 30 bars high pressure air used generally for starting of the engines and 7 bars low pressure air used for control and general service air. In the choice of an air compressors for applications requiring air above 7 bars, we generally use reciprocating air compressors as it has a more positive sealing in comparison to the other types of compressors like rotary vane, centrifugal, rotary screw etc. In reciprocating compressors the compression ratio of 1:7 is the limit due to the rise in temperature, thus to get 35 bars pressure the machine has to be a double stage compressor with intercooling. Most of the marine compressors used are two staged reciprocating compressors with intercooling and aftercooling.

Marine Reciprocating Engine

Uses Of Compressed Air Onboard Merchant Ships

* On merchant ships compressed air is used for a variety of uses some of which have been mentioned below:

* For automation and control of main engines, auxiliary engines, etc.

* For starting of the main engines, auxiliary engines, emergency generators, emergency fire pumps, etc.

* For heaving the life boat up by the use of an air motor.

* For pressurizing the hydrophores for domestic fresh water and sanitary water used in accommodation.

* For use in the sewage plant for conducting aerobic sewage breakdowns.

* For use in fog horns and ships whistles.

* For use in pneumatic tools like pneumatic grinder, pneumatic chisels, pneumatic drills, pneumatic spanners, etc.

* For use in painting operations.

* For general cleaning.

* For soot blowing of the boilers.

* Used in pneumatic pumps for oil transfer.

* And used as general service air

Unloading Of The Compressors

All compressors need to be unloaded during starting, stopping, and at regular intervals. It is for the following reasons:

1. During the starting of a motor the starting current is very high, so to avoid further overloading of the motor the compressor is started unloaded. When the current comes down to the running value, the unloader is closed and the compressor comes on load.

2. As the air is compressed in volume it releases a large amount of moisture. This oily water mixture is incompressible and if it is present inside the compression chamber it can damage the piston and the valves. For this reason also the compressor is started unloaded so that all the moisture present inside is drained.

3. At stopping the same is done so as to drain all the moisture inside and in preparation for the next starting.

4. Intermittently the compressor is unloaded to remove the condensed water inside which could go outside with the air.

For the purpose of unloading there are different types of unloaders some of them are pneumatic and some are solenoid operated. They all have a timer in the circuit which energizes the solenoid at the starting, stopping, and intermittently.

SAFETY FEATURES OF MARINE COMPRESSORS

Marine compressors have various safety features and cutouts installed so that they will trip when running in an unsafe mode. The compressors are reliable machines, but have to be maintained properly and in the proper intervals. There have been cases of the cylinder heads bursting and often resulting in fatalities. The various safety devices put in a marine compressor are as follows:

1. Lubricating oil low pressure trip

2. Cooling water high temperature trip

3. Motor overload trip and Motor overheating trip

OPERATING PROCEDURE OF A RECIPROCATING COMPRESSOR

The operating manual of the particular machine would give the specific items to be checked and the same must be read by the marine engineer upon joining the ship. However a rough guideline has been presented below:

1. Lubrication: check the oil level in the sump and in the lubricator tank.

2. Unloading: the valves in the unloading lines must be open.

3. Pressure gauge cocks: the cocks must be slightly open to avoid excessive pressure fluctuations which can damage the pressure gauges.

4. Air filter: check that the air intake filter is clean.

5. Cooling: check that the cooling water pressure is correct and in the case of attached pumps a visual check of the pump and all the valves in the line must be open.

6. Relief valves: some relief valves have hand testing levers given for testing, the same can be done.

7. Air line piping: check that all the valves in the discharge piping are open and correctly lined up.

8. Final check: the compressor can be turned a few revolutions with a turning bar to check for the free movement.

After the above checks have been made a compressor may be started with the unloaders open.

ROUTINE MAINTENANCE OF RECIPROCATING COMPRESSORS

Though the maintenance done on the compressors onboard would depend on the manufacturer’s advice and the planned maintenance program set up by the company, the below is a rough guideline about what is to be done for a new joining marine engineer.

1. Clean air filter at 250 running hours. Though neglected and often thought as ordinary, this filter is in fact very important as it is filtering the contaminants from coming inside the compression space and reducing abrasions on the liner surface. Also a dirty air inlet filter can raise the delivery temperature of the air to a dangerous level which can be well above the lubricating oil flash point and near the auto ignition point. Thus a badly maintained air inlet filter can cause an explosion.

2. Clean and inspect valves at 250 running hours. The valve is the heart of the compressor, and it operates once every revolution. The valves can be damaged due to impact forces or due to the ingress of foreign particles. Excessive lubrication also has been known to damage the valves. The valves should be removed, inspected, and overhauled at regular intervals. A broken valve can fall onto the piston and cause extensive damages, thus for this reason the valve maintenance is of vital importance.

3. Change crankcase oil at 500 running hours. Lubricating oil can lose its property over a period of time due to the onerous operating conditions. However the synthetic lubricating oils can be used for a longer period.

4. Check drive belts at 250 running hours. A v-belt is generally used to drive the cooling water pump. The tightness of the belt should be checked and adjusted to the correct value at proper intervals. In addition a belt dressing spray would protect the belts as well as increase the transmission of the power and reduce the slippage.

5. Check unloader operation at 250 running hours. At a regular interval the operation of the unloaders should be checked and if not satisfactory should be investigated and corrected.

The above is an example of the routine maintenance of the air compressors. In addition to the above at routine intervals the piston would have to be pulled out and the piston rings changed, bumping clearances checked, bearings changed. All this would be done on the basis of the planned maintenance program based on the manufacturer’s advice.

VALVES OVERHAUL PROCEDURE

The compressor must first be electrically isolated with the fuses removed and an electrical isolation and work permit granted by the chief engineer. Thereafter the first stage and the second stage suction and discharge valves should be removed and brought to the workshop for overhauling.

Marine compressors use the HOERBIGER automatic valves. The suction and the discharge valves look similar; however the direction of the operation and the spring stiffness differs. The suction valve springs are of lower spring stiffness than the discharge ones and they must never be mixed up. Also when using new spare parts the part number must be carefully checked from the operation and maintenance manual to avoid mixing them up.

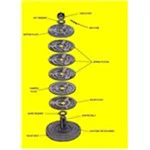

When opened up the suction valves are found to be in clean condition while the discharge valves would have some degree of carbonization. In case a valve is opened up and some parts are found to be broken, all the broken parts must be located to avoid any further damage to the machine. An exploded view of the compressor valve has been shown and the overhaul procedure is as follows:

1. Remove the split pin and open the castle nut.

2. Dismantle all the parts and soak in kerosene or clean diesel oil.

3. Clean all the parts with a soft brush. In case of a hard deposit a copper plate of washer can be used for the scraping action.

4. Check the valve plates and the valve seats for any damage and cracks. If any signs of fatigue cracks on the valve plates are present, then the valve plate must be replaced with new ones. The valve plate must never be turned over and used as it can lead to fatigue failure.

5. The valve plate and the valve seat must be separately lapped on a surface plate using fine and extra fine grinding paste.

6. Thereafter all the parts must be washed with diesel and cleaned with compressed air.

7. The valve should then be assembled, with the lapped surface of the valve plate and the valve seat facing each other.

8. After the assembly of the valve the operation of the valve should be checked by a soft wooden stick.

After the overhaul the valves have to be checked for leakage. The space above the valve plate should be filled up with water or light oil like kerosene. If after a few minutes no drop in level or leakage is there then the valve is satisfactory for the use. While installing care should be taken to avoid the interchange of the suction and the discharge valves, as it could lead to an explosion due to over pressurization of the compression chamber.

Compressor Automatic Valve

Troubleshooting Marine Compressors

Though the problems encountered onboard differ from ship to ship, a brief guideline is given regarding the causes of the different symptoms.

1. Lube oil pressure low: causes can be leakage in pipes, suction strainer choked, oil grade wrong, gear pump faulty, faulty pressure gauge, increased clearances of the bearings, and oil level low.

2. Cooling water high temperature: causes can be cooling water valves closed, cooling water piping blocked, cooling water pump belt lose or broken, cooling water pump faulty, no flow of cooling water, and low level of cooling water in the expansion tank.

3. Compressor noisy: causes can be bearings worn, crankshaft end play high, discharge pressure high, poor foundation, small bumping clearance, piston rings worn, liner worn out causing piston slap, valves not properly seated, and valves broken or faulty.

4. First stage discharge pressure low: causes can be that the first stage suction valve is not closing fully and allowing the air to leak during the compression or it is not opening fully allowing less air to come in the chamber or the discharge valve is faulty and opening prematurely or incorrect springs have been fitted which are compressing on little pressure, intake filter fouled, leakage from piston rings.

5. First stage discharge pressure high: causes can be that the second stage suction valve is not holding and while compression high pressure air is coming to the intercooler and showing an increase in the pressure, intercooler tubes choked.

6. Second stage discharge pressure low: causes can be leakage from the piston rings, second stage suction valve faulty and allowing the air to escape, second stage discharge valve leaking or opening prematurely due to wrong springs fitted.

7. Second stage discharge pressure high: causes can be obstruction in the after cooler, obstruction in the discharge valve, air bottle pressure high, second stage discharge valve springs very stiff.

The above is just a brief exposure to the problems encountered onboard and how it must be investigated. An experienced marine engineer keeps an eye on the parameters and knows when maintenance is expected.

Conclusion

A compressed air system used onboard is very important to the marine engineer and without any air the ship would soon become a dead ship. The various parts of the compressed air system, be it the compressors, the pipe lines, or the air bottles have to be maintained in good condition. In this article a brief guideline has been given about the compressors used onboard, use of compressed air onboard, the safety devices fitted, the importance of unloading during starting, the operating procedure, the basic maintenance, the valves overhaul procedure and the trouble shooting have all been discussed.