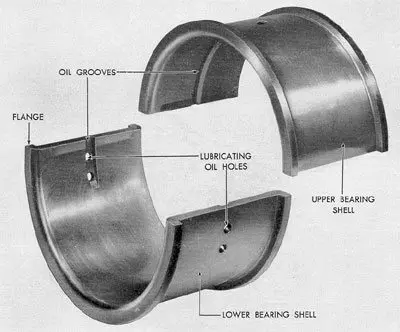

The rotational power of a ship’s propeller is determined by the power produced by the marine engine to rotate the crankshaft. The crankshaft of the main engine is supported and connected to the connecting rod via main Bearings whose main function is to transmit the load without any metal to metal contact.

This is achieved by choosing special materials for manufacturing main bearings which floats the journal pin of the rotating crankshaft when lube oil is supplied to it.

Properties of main bearing materials

· It must be anti-friction resistant

· It must be of anti-corrosive type

· Good running in and grinding in ability

· Good load carrying capacity

· Good embeddability property

· Must support the oil film

· Good tensile and compressive strength

· Must not react with the lube oil

· It must have thermal resistant property to avoid any damage in case it’s running hot

Types of Main Bearing

In maritime industry, there are three famous types of Main bearings used for both propulsion engines which are normally 2 stroke engines and power generation engines which are 4 stroke engines, they are as follows:

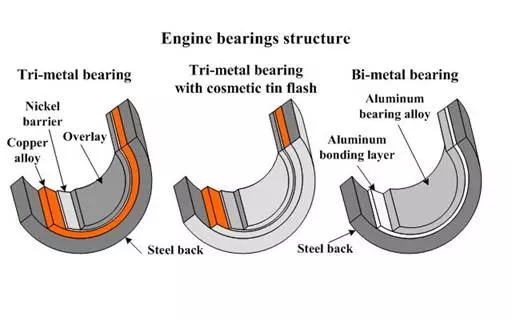

1. Lead Bronze Bearing: This bearings consist of the following layers

· Flash layer: It is the top most layer with thickness of 0.035mm made up of tin and lead. It is used to protect the bearing from corrosion and dust when not in use. This layer flashes off when bearing is running.

· Nickle Barrier: It is the second layer made up of nickel with thickness of 0.02mm. Its main function is to prevent corrosion and avoid diffusion of tin into bearing metal.

· Lead Bronze: The third layer composed of lead bronze which has an excellent anti seizing property and is the principle component which acts as a bearing out of all layers.

· Steel back: Steel back is the last and backing part of the bearing used for shape and support over which all the layers are bonded together.

Gudgeon Pin bearing in a 4 stroke engine is usually made of lead bronze bearing and also used for main bearing for smaller engines.

2. Bi-metal Bearing: This bearing consists of following layers

· Aluminium Tin: The first layer of bi metal consists of Al and Sn with thickness of 0.5 to 1.3mm and this is the main element of this type of bearing.

· Bonding Layer: The bonding layer consists of aluminium and it is 0.1mm thick. The main function of the bonding layer is to obtain a good bond between the shell and the top layer.

· Steel Back: The backing part used for shape and support.

This type of bearings are used in 4 stroke engine main bearings

3. Tri Metal Bearing: These bearings are called tri metal bearing because they consist of three main layers (excluding

flash layer as it flashes off) and a steel back. It consists of-

· Flash Layer: It is the top most layer with thickness of 1 micron made up of tin and lead and used to protect the bearing from corrosion and dust when not in use. This layer flashes off when bearing is in Running in period.

· Overlay: The second layer made up of white metal (Tin Antimony Copper) which is the main component in this type of bearing. Its thickness is 20 microns.

· Interlay: It is the third layer used as anti corrosive layer for overlay. It is of 5 microns thickness.

· Lining: It is the lining layer between interlay and steel back with thickness of 1 mm made up of lead and bronze.

· Steel Back: The backing part used for shape and support.

Used in 2 stroke Main bearing shell