The first diesel – battery electric hybrid tugboat Carolyn Dorothy has been built and is operating in San Pedro Harbor. The distinctive design combines a diesel engine, power generator, batteries and main drive electric motors/generators, reducing fuel consumption and emissions to the atmosphere.

Introduction to the First Diesel-Battery Electric Hybrid Tugboat

The Carolyn Dorothy is a hybrid tug, being of a diesel electric design, with a few added innovative ideas.

However, being a hybrid design does not affect her pulling power as she can handle the same tonnage of ships as her sister tugs, only more efficiently and environmentally friendly.

The tug was a joint design by Foss Rainier Shipyards, who built and now operate her.

This is an article in marine engineering, and in particular the operation of a hybrid tug operating in the very busy San Pedro Harbor, California.

We begin with a quick look at the history of steam/diesel electric ships, how typical diesel electric ships operate, and then examine the Carolyn Dorothy.

History and Operation of a Diesel Electric Ship

Many types of merchant and navy ships have been powered by turbo or diesel electric motors for over a hundred years. I remember when I was at sea in the sixties, seeing an American T2 oil tanker in the Persian Gulf, being a survivor of the 2nd world war and still sporting her grey paint. These tankers were mass produced and a number were turbo-electric drive.

During World War 2, submarines were diesel electric, the diesel charging the batteries that drove the prop shaft whilst submerged.

Today numerous modern cruise liners including Cunard’s Queen Mary 2, and naval ships of all nations are turbo or diesel electric driven. The drive motors are a very efficient and versatile design allowing greater maneuverability and shaft torque.

There are many advantages of this type of drive over the conventional diesel direct drive, the main advantages being efficiency increase and reduced emissions to the atmosphere.

Carolyn Dorothy: The First Diesel-Battery Electric Hybrid Tugboat

As can be seen from above image the hull of the hybrid tug appears identical to the other Dolphin class tugs it is working alongside in San Pedro Harbor.

However here the similarity ends, the engineroom contains the hybrid designed power units, their specification is listed below;

Main engines – 2 x Cummins QSK50 main engines, each producing 1342kW at 1800 rpm, reduced to 270 rpm through a gearbox driving the props.

· Power generation – 2 x Cummins QSM11 generators, each producing 300kWe.

· Batteries – 126 x 12 volt, marine deep cycle gel lead-acid batteries.

· Electric drive – 2 x 746kW Electric Siemens Shaft Motor/ generators located on the output shafts, operated by clutches.

· Propellers – 2 x 2.4m dia, 4 bladed propellers incorporated in Azimuth Thrusters.

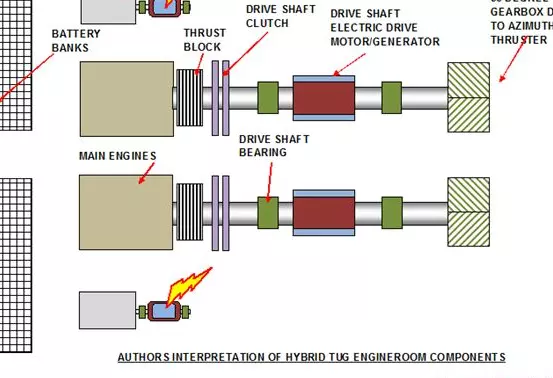

I have included a layout of the engineroom of the hybrid tugboat, (as I see it) and typical stern drive Azimuth Thrusters

There are numerous configurations for using the hybrid engines; however the designers have selected four applicable modes;

1. Minimal Emission – power is supplied by the batteries for the normal ships services as when tied up. This mode is also used for short runs of 4 knots, powered by the shaft generator/motors. This mode is used 65% of the time.

2. Eco Cruise – this mode is used for barge work and typically uses both generators to provide power to the driveshafts via the shaft motor/ generators, and is used 13% of the time.

3. Mid Range – for up to 45% power, both main engines are used. This mode is used 15% of the time

4. Full Power – both main engines plus the two power generators are used in this mode, used 7% of the time.

The Engineroom Components of the Hybrid Tugboat.

The components are used to drive the hybrid tugboat in the following manner;

· Main Engines – used to drive the tugboat via main shafts. The main shaft drive can also charge the batteries via the motor/generator, in the generator mode.

· Power Generators– used to charge the batteries, and drive the main shafts through the shaft electric motor/generator, in the motor mode, along with main engines when working at maximum HP.

Batteries – used on standby and when tied up, they can also be used to drive the shaft through shaft electric motor/ generator in the motor mode for short periods. The batteries can also be charged from shore-side electric supply when tied up alongside.

It is the combination of these three major components which make the Carolyn Dorothy a unique design that can be fitted retrospectively to most tugboats, and indeed to larger sea-going vessels. This is a fine example of a shipbuilder / owner and operator being in the forefront of environmental considerations of ships exhaust gas emissions to atmosphere.

Comments are closed