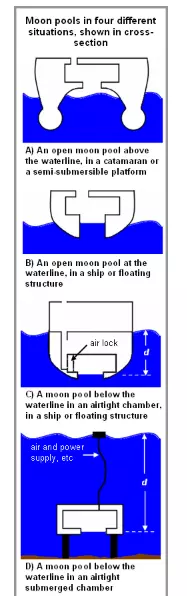

It is a mobile offshore installation akin to a ship which is specialized for exploration and drilling of oil and gas resources more specifically for scientific exploratory purposes. Mostly, it is used for deep and ultra deep applications involving exploratory and drilling purposes. The first drillship was the CUSS I, designed by Robert F. Bauer of Global Marine in 1955. The CUSS I had drilled in 400 feet deep waters by 1957.Apart from regular drilling purposes, the drillship may also be used for maintenance and surveillance purposes such as casing and tubing installation, subsea tree installations or wellhead capping. Drillships though expensive and of high precision in operating and maintenance, is often believed to be the most proficient mode of offshore technology trend where like any conventional ship, it can be transferred from one place to another anytime and that too without the use of any tugs , heavy lift ships or any other towing system. However a mandatory mooring system should be kept or a DPS positioning system should be employed. Generally, underneath the derrick through the hull is the moon pool which connects the deck to the sea directly. Sounds pretty interesting, isn’t it ? The moonpool is generally an opening of the deck floor with the water in any marine research vessel, drillship, sometimes icebreakers, diving support vessel for easy exposure to the underwater environment or for the easy steup of the drilling equipment as done here. Generally moonpools are situated in four different positions, above the waterline, at the waterline, underneath the waterline or deep submerged depending upon the requirements, the vehicle or the design. So, for a drillship the moonpool provides easy accessibility for the drill equipment or manpower for the purpose of maintenance of the drill equipment or underwater survey. However immense care has to be taken during the design stage to ensure the moon pool compensates the loss of strength in the deck or hull, maintain stability and trim and avoid flooding or leakage.

A simple way to understand what a drillship is to do in order to drill, a marine riser is lowered from the drillship to the seabed with a blowout preventer (BOP) at the bottom that connects to the wellhead. All this is done through the moonpool intricate to the hull. Drillships also have their own storage and processing system . However, in terms of positioning and stagnancy during drilling operations, the semi-submersibles have an upper hand.

Fig ; Tiger series drillship

Comments are closed