Anchors play a critical role in the maneuvering of ships and aid them in safely docking at ports and on the high seas. To keep an entire vessel (weighing a few hundred tons) in place, a heavyweight known as the anchor head provides the resistive forces.

Have you ever wondered how such a heavyweight is lowered and raised from the ocean bed or seafloor?

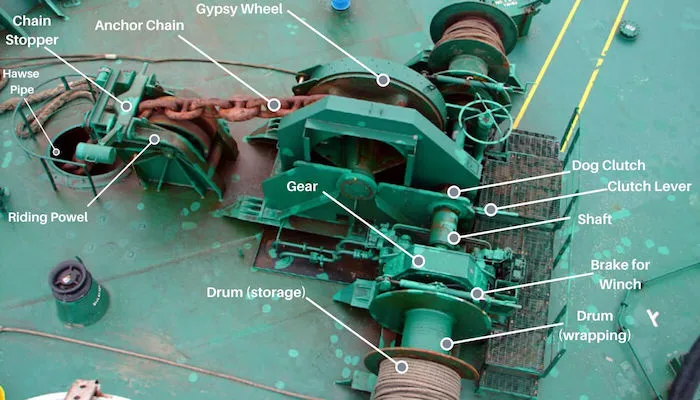

A mechanical device known as the anchor windlass is used for this very purpose.

A windlass refers to any pulley or mechanical system used to shift large weights in a vertical or horizontal direction. It was invented by the ancient Greek scientist Archimedes and was used for general purposes such as to draw water from wells or to aid in lifting heavy construction equipment.

As technology advances have placed larger demands on the shipping and goods transport industry, heavier anchors required to stop larger ships have also been pressed into service.

Owing to this, advanced anchor windlass systems have also been used to effectively operate the anchor and associated machinery. In this article, we will examine what an anchor windlass is, and how it operates.

Basic Design of a Windlass

A windlass is any device used to move considerably heavy weights using a pulley system. A barrel with a chain or cable wound around it is operated using a belt or crankshaft. This shaft provides a circular motion that is able to lift heavy weights without having to expend the energy needed to normally haul it.

The crank can either be operated manually (as in the case of drawing water from wells) or using a motor (used in large construction cranes) and is attached to the barrel in such a way that it can rotate about a central axis.

The principle behind using a pulley design is that large weights can be lifted by distributing the load between multiple cables instead of a single chain. Thus, by exerting a limited amount of effort, a considerably heavier load can effectively be raised.

The issue with using such types of designs is that a large strain is placed on the cable or chain used to shift the load. In case the mechanism is stopped midway through operation, adequate steps have to be taken to prevent the cable from breaking under tension.

Most materials can suffer from fatigue or stress-related failure under loads of tension. Thus, for an anchor windlass that has to lift a weight of nearly a ton, specialized mechanisms have to be used to ensure that the weight of the anchor head is taken off the anchor rode while the operation is stalled. This will be discussed in further detail in the below sections.

Comments are closed