There are many oil and gas discoveries which are out of reach of fixed structures for one reason or another. They may be in extremely deep water, or the oil or gas deposit might be too small or too widely spread to warrant the high cost of building a fixed structure. In these cases, seabed-completed wells may be connected to a floating platform moored above the field, using a production marine riser. The limiting conditions for fixed installations are not clearly defined, and they have been used in some cases for depths of over 250 meters, although this is in a benign environment. Floating platforms can also be used as the basis for an Early Production System (EPS), in which the appraisal wells drilled from a floating drilling vessel are completed at the seabed and produced to a floating platform carrying the required process plant and other facilities. This allows production to begin and create income whilst a fixed platform is being designed and installed for full field development. In this article, there are some discussions about three main types of floating offshore structures which are Tension Leg Platforms, SPAR and FPSO.

Tension Leg Platforms (Tethered Buoyant Structures)

One more form of offshore platform is what is known as the Tension Leg Platform, or Tethered Buoyant Structure. This method is intended for oil and gas production from water depths of over 500 meters. The platform works in much the same way as a taut moored buoy, which is anchored to the seabed using a vertical wire. The Tethered Buoyant Structure is basically a large, semi-submersible floating vessel, which uses a heavy gravity anchor to moor it to the seabed. Tension force is maintained in these vertical cables by adjusting the buoyancy of the floating platform, to ensure positive tension at all times. This method reduced marine response in the platform to effectively zero in vertical terms, and very little in horizontal terms. Horizontal drift can be further reduced as necessary. By using buoyance against a tension mooring system, this allows the use of a semi-submersible floating platform which can carry an additional load, balancing this out by increasing the buoyancy.

This type of structure is still under development, and there are still many problem points to iron out. How widespread it will become in the future is largely dependent on solving these issues, along with a thorough economic assessment comparing the system to other available ones.

Figure 1 – Tension Leg Platform

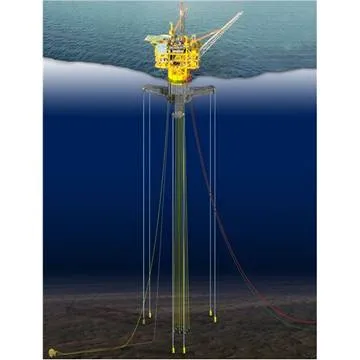

Example of Tension Leg Platform: Magnolia Platform (Figure 2) is an offshore oil drilling and production Extended Tension Leg Platform in the Gulf of Mexico. It is the world’s deepest ETLP, reaching 1,432 m, beating the Marco Polo TLP by 120 m

Figure 2 – Magnolia Platform

SPAR

SPAR, which takes its name from the nautical term for booms and masts on a ship, is designed to present a small profile with minimal effect on wind and current. It uses an elongated cylindrical structure which floats in much the same way as an iceberg. This is moored to the seabed using steel or polyester cables. To keep a low center of gravity and prevent the SPAR from tipping over, the bottom of the SPAR features a ballast made of a heavy material, such as magnetite iron ore. Due to the shape of its underwater profile, the SPAR is more vulnerable to vortex shedding (eddies), which can result in significant vibrations. To offset this, strakes are built into the frame.

Floating Production Storage & Offloading (FPSO)

A Floating Production, Storage and Offloading (FPSO) unit is a floating vessel used by the offshore oil and gas industry for the production and processing of hydrocarbons, and for the storage of oil. A FPSO vessel is designed to receive hydrocarbons produced by itself or from nearby platforms or subsea template, process them, and store oil until it can be offloaded onto a tanker or, less frequently, transported through a pipeline. FPSOs are preferred in frontier offshore regions as they are easy to install, and do not require a local pipeline infrastructure to export oil. FPSOs can be a conversion of an oil tanker or can be a vessel built specially for the application. A vessel used only to store oil (without processing it) is referred to as a Floating Storage and Offloading vessel (FSO).