Emission from ships exhausts account for a 2-3% of all global CO2 emissions, along with quite sizeable amounts of SOx and NOx emissions. However, the International Maritime Organization (IMO) has capped the NOx in exhaust emissions and reduced the sulfur content in HFO used by ships main engines.

An Overview of Heavy Fuel Oil

The crude is partially cleaned up on the offshore oil production platform, from where it is pumped ashore through sub-sea pipelines. When the crude reaches the refinery, it is subjected to further dewatering and filtration then heated to 659°F. It is then fed into the Atmospheric Distillation Unit where the different factions are drawn off, and sent for further processing to petroleum and diesel oil, etc. This leaves a residue at the bottom of the column, known appropriately as “bottoms.”

It is from these bottoms that the residual fuel is drawn off; the remainder of the bottoms is fed into the Vacuum Distillation Unit where they are further treated under vacuum.

The sulfur content at this stage of processing can be as high as 6% m/m and must undergo further processing to reduce the content to IMO 2010 regulations of 4.5%. (The measurement m/m represents the percentage mass of sulfur dioxide gasses in the total mass of the emissions.)

Regulations Governing Exhaust Gas Emissions from Ships Engines

Image: Smoking Cruise Ships on the Nile from Wiki Commons by Remih

Due to the effect of ships main engine exhaust emissions to the atmosphere (as above), new legislation on stricter control and limits of ships exhaust emissions of oxides of nitrogen (NOx’s) along with oxides of sulfur (SOx’s) are in place.

NOx Emissions

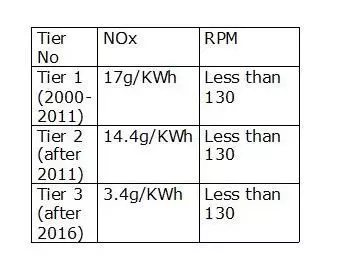

These limits have been laid down by the International Maritime Organization (IMO) through the “International Convention on the Prevention of Pollution from Ships” known as MARPOL 73/78. The legislation for emission of NOx’s is in three tiers, being shown in tabular form below;

Author’s Notes:

1. Permitted NOx emissions are set according to the engine RPM; I have selected 130 RPM since low revving ships main diesel engines are the most popular.

2. The emissions of NOx are a product of the combustion air that contains oxygen and nitrogen. Therefore it can be controlled by designing the engine to operate at optimum efficiency, using the most modern components, and, when running maintaining engine temperatures to achieve this.

SOx Emissions

MARPOL have stipulated that the Emissions (SOx) are controlled by the removal of sulfur from the HFO, effectively creating a low sulfur HFO, or by the use of exhaust gas scrubbers as an alternative.

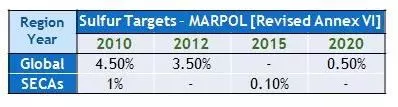

The permitted sulfur content in HFO is shown below;

○ 4.5% m/m prior to January 2012.(Current)

○ 3.3% m/m after January 2012

○ 0.5% m/m after January 2020

The table below shows permitted levels of sulfur in HFO both in Europe and Globally.

Image: MARPOLE 6 Sulfur Targets from Wiki Commons by Pisco.

Some engine manufacturers preferred to use fume treatment plants in the form of scrubbers in lieu of the reformulation of heavy fuel oil. To accommodate them MARPOL have set limits on SOx emissions at 6g/KWh (as SO2) after scrubbers. But remember there is still the effluent to get rid off!

The next section deals with the processing of HFO in terms of energy use and emissions during reformation of the fuel.

Desulfurization of Heavy Fuel Oil Processing – Energy and Emissions

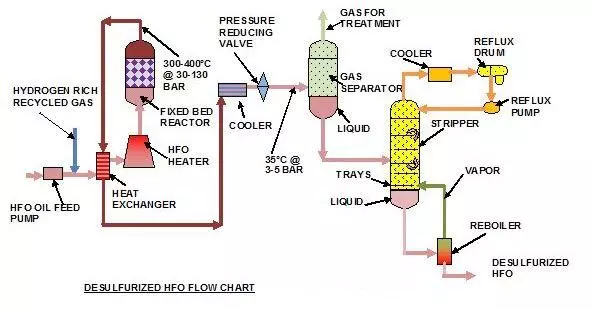

Hydrogen-rich recycled gas is injected to the HFO before it is pumped through a heat exchanger. From here it is fed through a fired heater where it is heated to 300-400°C @ between 30 and 130 bar, causing it to become vaporized.

This vapor now passes through a fixed bed reactor where in the presence of a catalyst, a hydro-desulfurization reaction occurs.

The resultant gas is then cooled to 35°C and 5 bar before being passed through the stripper tower where any remaining H2S is removed. The liquid gathering at the bottom of the stripper is the desulfurized heavy fuel oil. One method of achieving this is shown below.

Now, this process is quite efficient but energy intensive due to the high temperatures and pressures required in circulating and vaporizing the HFO. This is accompanied by the emissions of gasses to the atmosphere that consist largely CO2, one of the most prominent of the greenhouse gasses.

So, we have to weigh up the damage caused by these gasses produced in the desulfurization process against the benefit of the reduction in sulfur dioxide and decide if the process is worth while.

According to some of the leading scientists who are experts on these matters, the CO2 produced will increase total anthropogenic emissions by 0.01%, but make savings of overall SOx emissions from combustion of the desulfurized HFO by ship’s engines of 6%.

As a marine engineer I tend to support the desulfurization of the HFO, not only because of the reduction in SOx emissions to the atmosphere, but the added benefit to the ships engines running on low-sulfur fuel.

I have seen the damage to pistons, liners, fuel injectors and pumps through sulfuric acid attack, as well as the problems caused by acid entering the lube oil system. The penalty to the ship owners is of course the cost of the reformulated fuel. However, this must be compared with the savings on engine parts/maintenance, and lube-oil changes, before deciding to use the low-sulfur fuel or, to fit gas scrubbers to mitigate the SOx in their ships exhaust system.

Comments are closed