Propellers are be classified on the basis of several factors. The classification of different types of propellers is shown below:

A) Classification by Number of Blades Attached:

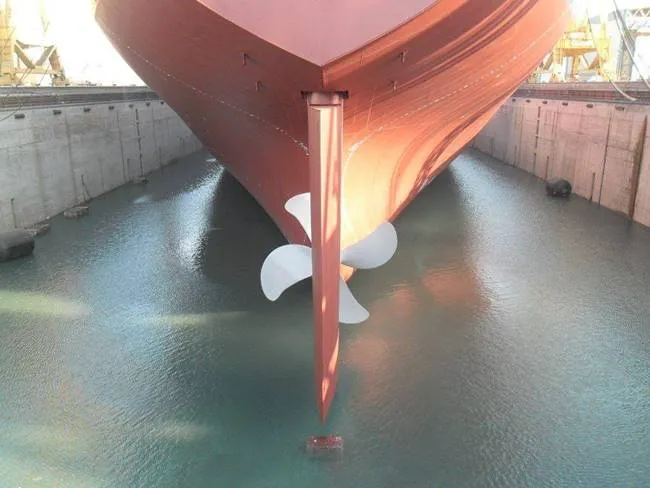

Propeller blades may vary from 3 blade propeller to 4 blade propeller and sometimes even 5 blade propeller. However, the most commonly used are 3 blades and 4 blade propellers.

However, the most commonly used are 4 blades and 5 blade propellers.

The propeller efficiency will be highest for propeller with a minimum number of blades i.e. 2 blade propeller. But to achieve strength factor and considering the heavy loads subjected by the ship, sea and weather two-blade propellers are not used for merchant ships.

3 blade propeller

A 3 blade propeller has the following characteristics:

· The manufacturing cost is lower than other types.

· Are normally made up of aluminium alloy.

· Gives a good high-speed performance.

· The acceleration is better than other types.

· Low-speed handling is not much efficient.

4 blade propeller

A 4 blade propeller has the following characteristics:

· The manufacturing cost is higher than 3 blade propellers.

· 4 blade propellers are normally made up of stainless steel alloys.

· Have better strength and durability.

· Gives good low-speed handling and performance.

· Has a better holding power in rough seas.

· 4 blade propeller provides a better fuel economy than all the other types.

5 blade propeller

A 5 blade propeller has the following characteristics:

· Manufacturing cost is higher of all.

· Vibration is minimal from all the other types.

· 5 blade propellers have better holding power in rough seas.

6 blade propeller

· Manufacturing cost is high

· Vibration is minimal from all the other types.

· 6 blade propellers have better holding power in rough seas.

· With six blade propeller, the induced pressure field over the propeller decreases

Large container ships are mainly fitted with 5 or 6-bladed propellers.

B) Classification By pitch of the blade:

Pitch of a propeller can be defined as the displacement that a propeller makes for every full revolution of 360 ̊. The classification of the propellers on the basis of pitch is as follows.

Fixed Pitch Propeller

The blades in fixed pitch propeller are permanently attached to the hub. The fixed pitch type propellers are casted and the position of the blades and hence the position of the pitch is permanently fixed and cannot be changed during the operation. They are normally made from copper alloy.

Fixed pitch propellers are robust and reliable as the system doesn’t incorporate any mechanical and hydraulic connection as in Controlled Pitch Propeller (CPP). The manufacturing, installation and operational costs are lower than controlled pitch propeller (CPP) type. The manoeuvrability of fixed-pitch propeller is also not as good as CPP.

These type of propellers are fitted in a ship which does not have good manoeuvrability requirements.

Controllable Pitch Propeller

In Controlled Pitch type propeller, it is possible to alter the pitch by rotating the blade about its vertical axis by means of mechanical and hydraulic arrangement. This helps in driving the propulsion machinery at constant load with no reversing mechanism required as the pitch can be altered to match the required operating condition. Thus the manoeuvrability improves and the engine efficiency also increases.

This drawback includes the possibility of oil pollution as the hydraulic oil in the boss which is used for controlling the pitch may leak out. It is a complex and expensive system from both installation and operational point. Moreover, the pitch can get stuck in one position, making it difficult to manoeuvre the engine.

However, the propeller efficiency for the CP propeller is slightly lower than the same size FP propeller due to the larger hub to accommodate the blade pitch mechanism and pipings.

Propeller Dimension: As a general rule, a larger diameter propeller will be more efficient. But the real dimension of the propeller will depend on the type of ship it will be used for and the following factors:

1. Aft body construction and design of the ship

2. Clearance requirement between the tip and hull of the ship

3. General ballast condition of the ship. For tankers and bulkers, the propeller size will be small as compared to containers

4. The design draught of the ship

approximate value Propeller dimension

· For Container ship d/D = 0.74

· For Bulk carrier and Tanker d/D = 0.65

Comments are closed